- Home

- Technical Products

Enterprise Cloud IT Solutions

Test Measurement

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Latest Articles

- About Us

EN

EN

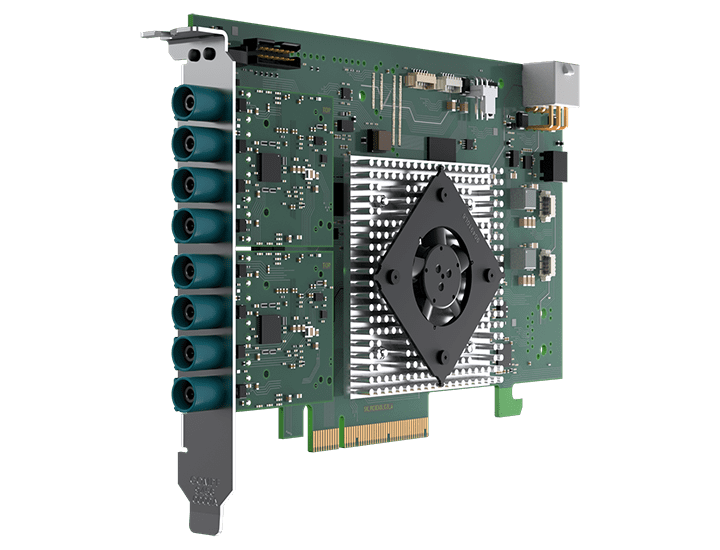

proFRAME Modular Image Capture and Injection Boss Card

GMSL, FPD-Link Adapters Compatible with Different Automotive Camera Tests

proFRAME, jointly launched with Solectrix, is an ideal solution for ADAS system or autonomous driving function verification, hardware-in-the-loop testing, HIL injection, in-vehicle display testing, and smart cockpit testing. proFRAME is a single card that can capture/inject/bypass raw video streams for various applications. It supports 8 simultaneous 10Gbit/s video streams, 4 inputs and 4 outputs, and is compatible with common SerDes protocols, such as GMSL2™ and GMSL3™, FPD-Link™ III and IV, and GVIF.

proFRAME | Modular Image Capture and Injection Boss Card

Product Selection

Product Selection

Core advantages

Core Strengths

Application scenarios

Application Scenarios

Application case

Client Cases

Technical Resources

Technical Resources

Inquire/Buy Now

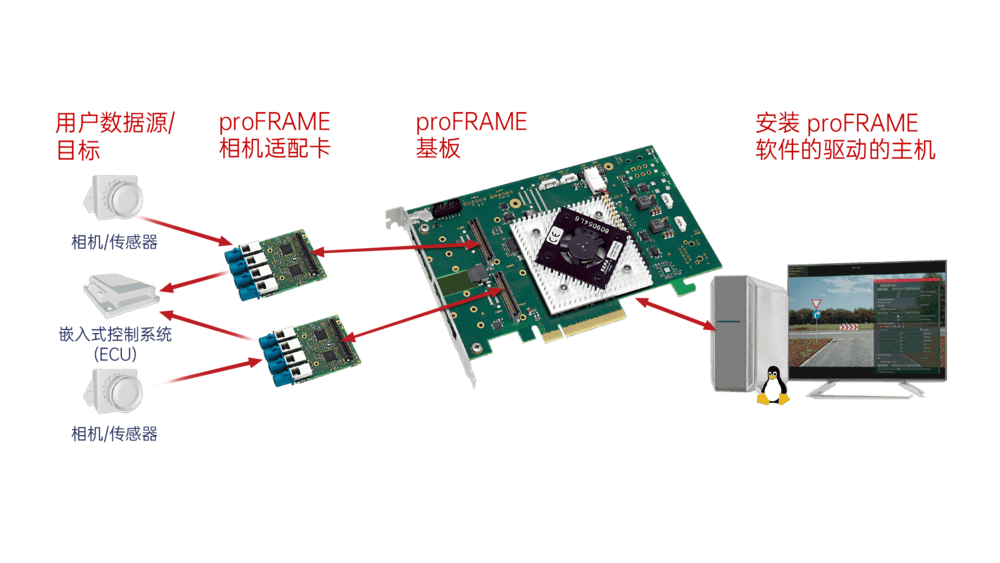

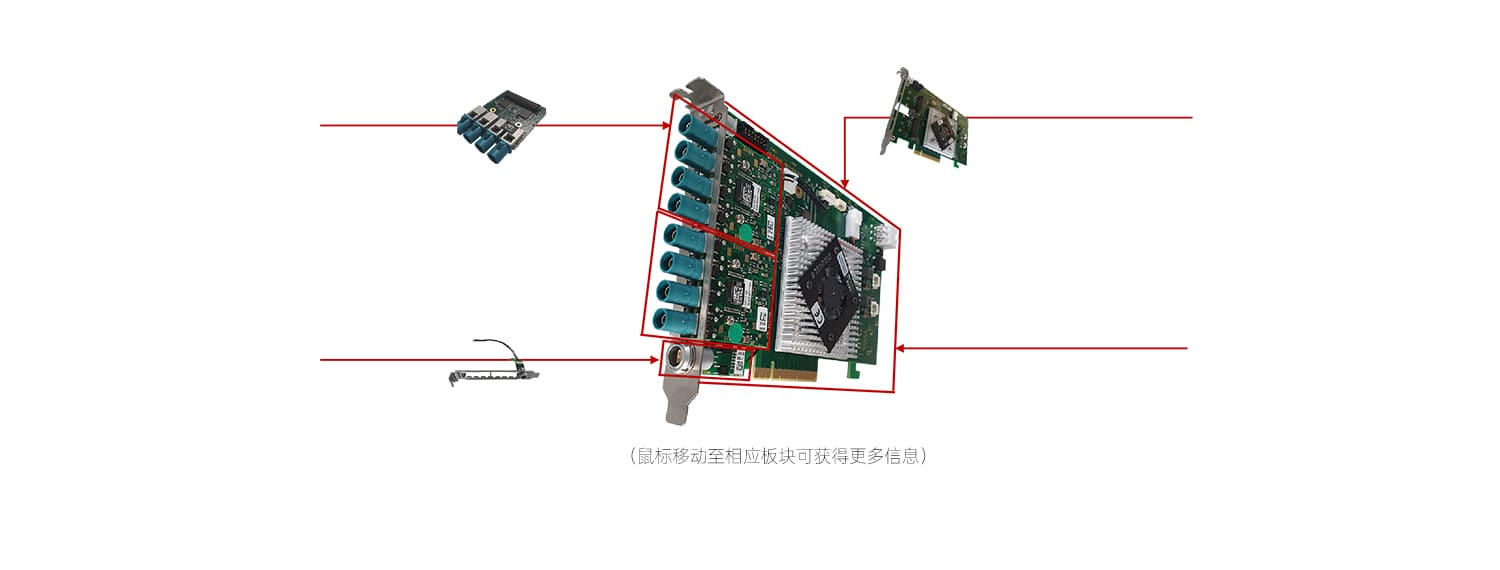

System Composition and Selection

System composition and selection

Baseboards:Powerful FPGA-capable plug-in card for real-time data processing and precise time stamping with proFRAME camera adapter slot for up to 8 cameras. Different adapters are supported depending on hardware generation and product variant.

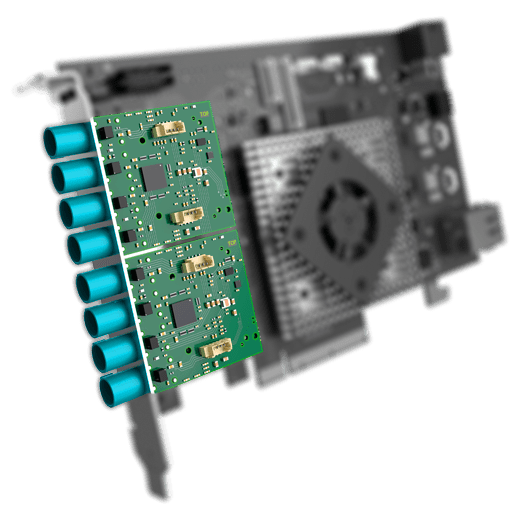

Camera adapter:Includes camera interface and mounts on the corresponding proFRAME substrate.

Software:Integrate the proFRAME Boss Card into your Windows or Linux® system, including GPU accelerated software libraries, sample applications

Accessories:Expansion modules for different scenarios, including Thunderbolt Box (PCIe slot expansion), ledAD3 (LED synchronized illumination module), and Synchronized Trigger Module (Synchronized Trigger Clock signal in/out).

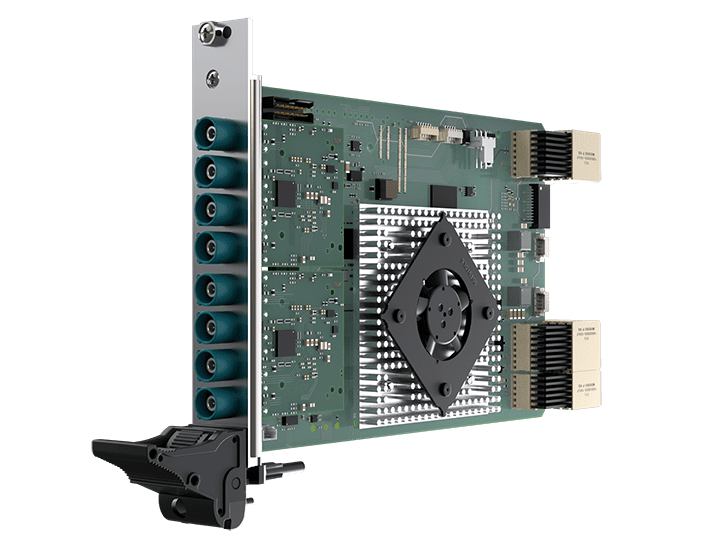

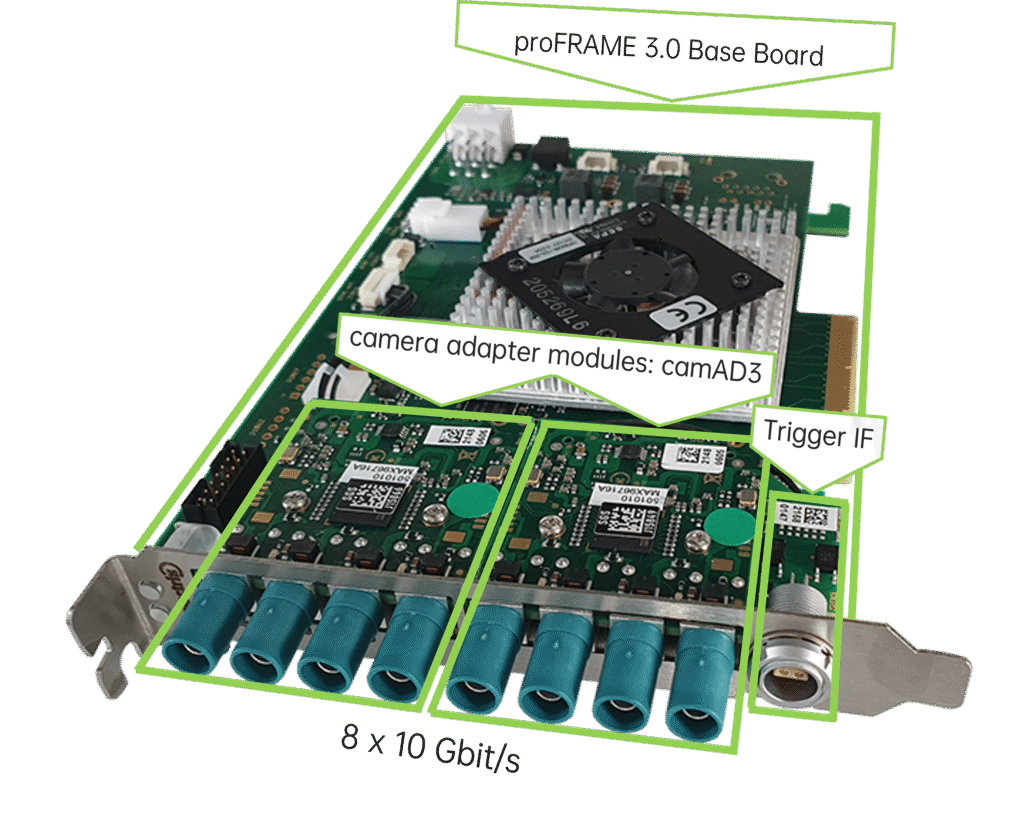

proFRAME Base Board 3.0 CompactPCI Serial

3U CompactPCI® Serial Port (CPCI-S.0)

Baseboard built around AMD Zynq™UltraScale+™ ZU4CG MPSoC, which increases data acquisition rates up to 40 Gb/s per new camera adapter interface

proFRAME Base Board 3.0 PCIe

PCIe® x8 Gen3 Interface (64 Gbit/s)

Baseboard built around AMD Zynq™UltraScale+™ ZU4CG MPSoC, which increases data acquisition rates up to 40 Gb/s per new camera adapter interface

proFRAME camera adapters are available in multiple models.

MaxicoM/TI Serial Deserialization Chip, Native Data and I2C Control

A wide range of models are available, including adapters for GMSL™ 1/2/3 and FPD-Link™ III/IV, as well as common (de)serializers (ADI Devices/Maxim, Texas Instruments) to ensure compatibility with all camera types. Additional camera adapters, e.g. for GigE Vision®, Camera Link®, etc., are available upon request.

proFRAME software libraries

Integrate the proFRAME card into your Windows or Linux® system.

Includes drivers and image sources for baseboards, cameras and sync adapters, GPU-accelerated software libraries for image signal processing functions, and a variety of simple sample applications for basic camera control

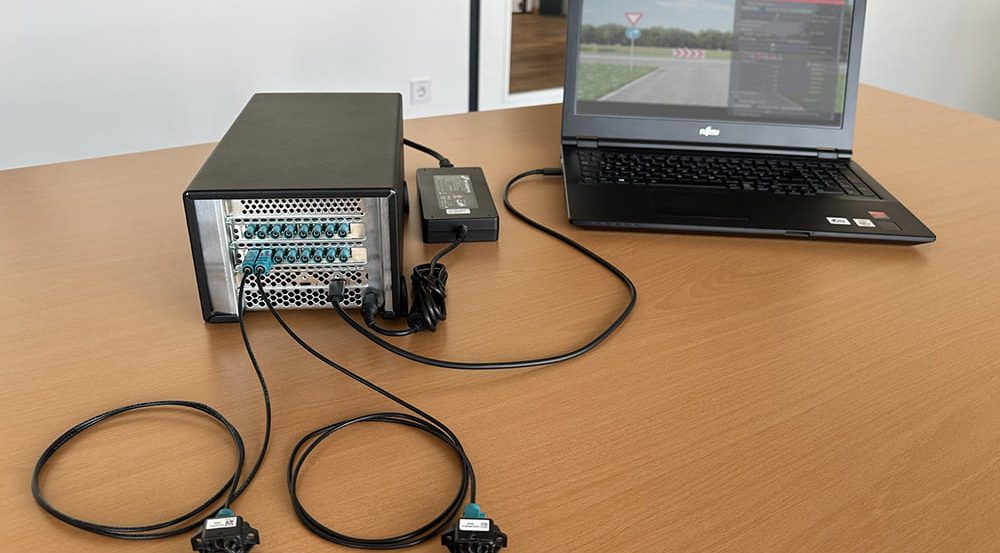

proFRAME 3.0 Thunderbolt 3 Box

Enables proFrame to connect to a Thunderbolt 3 port on a PC or laptop.

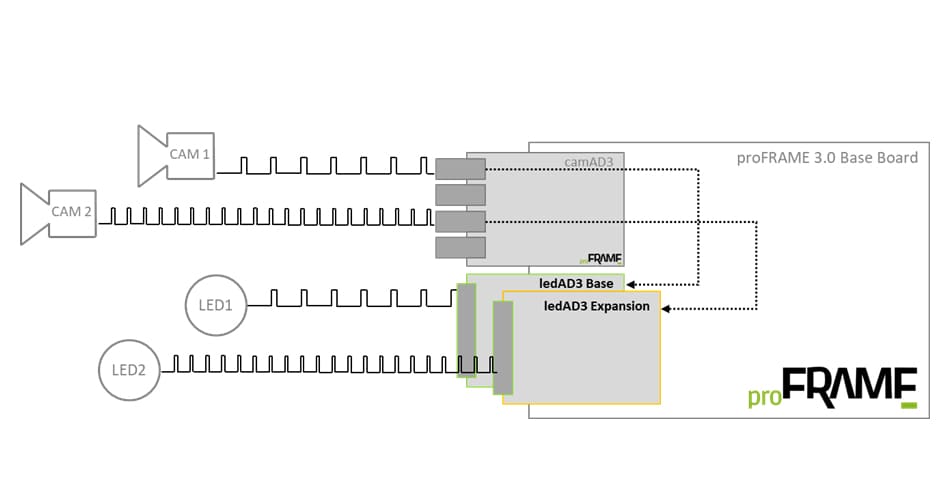

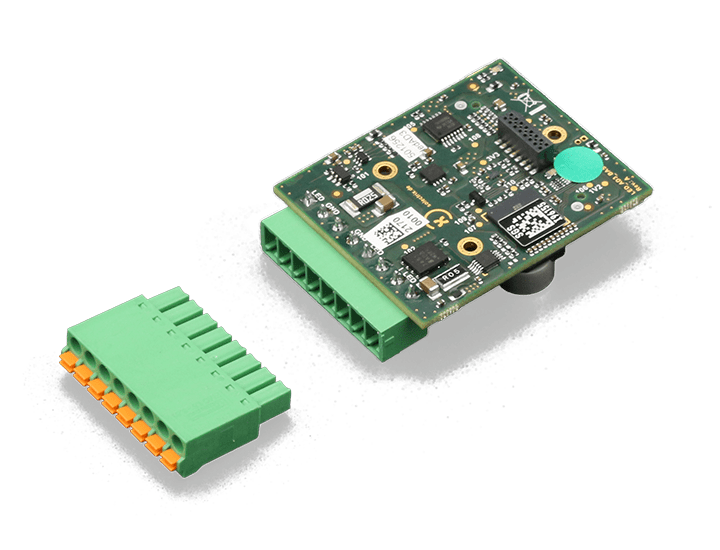

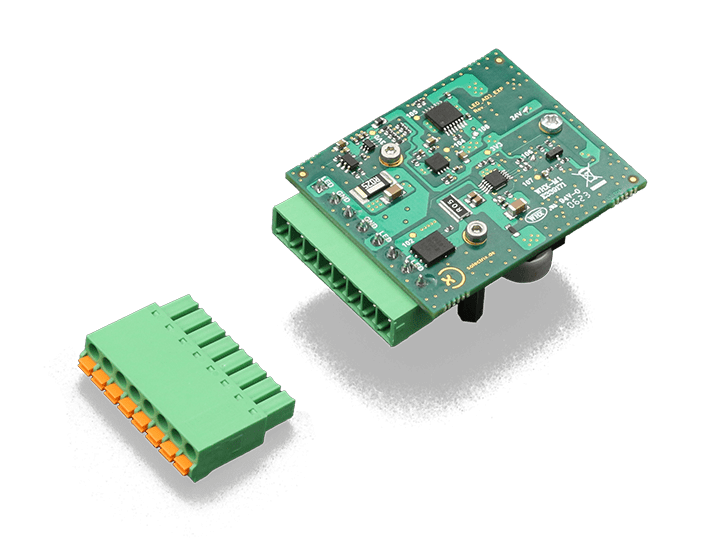

ledAD3 Base

The user is able to control an LED that is synchronized with the trigger signal of a specific camera.

ledAD3 Expansion

Controls the synchronized switching of LEDs from the second camera's triggering signal

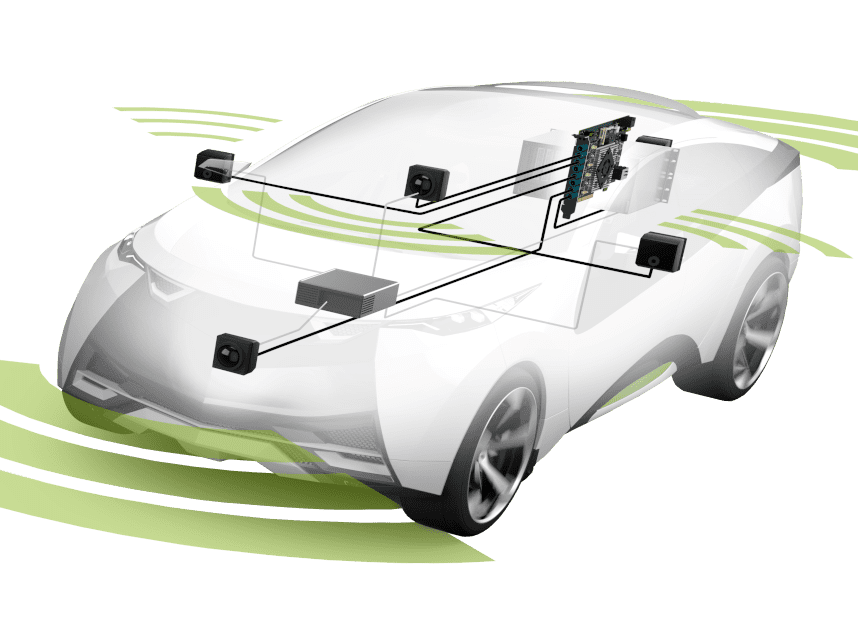

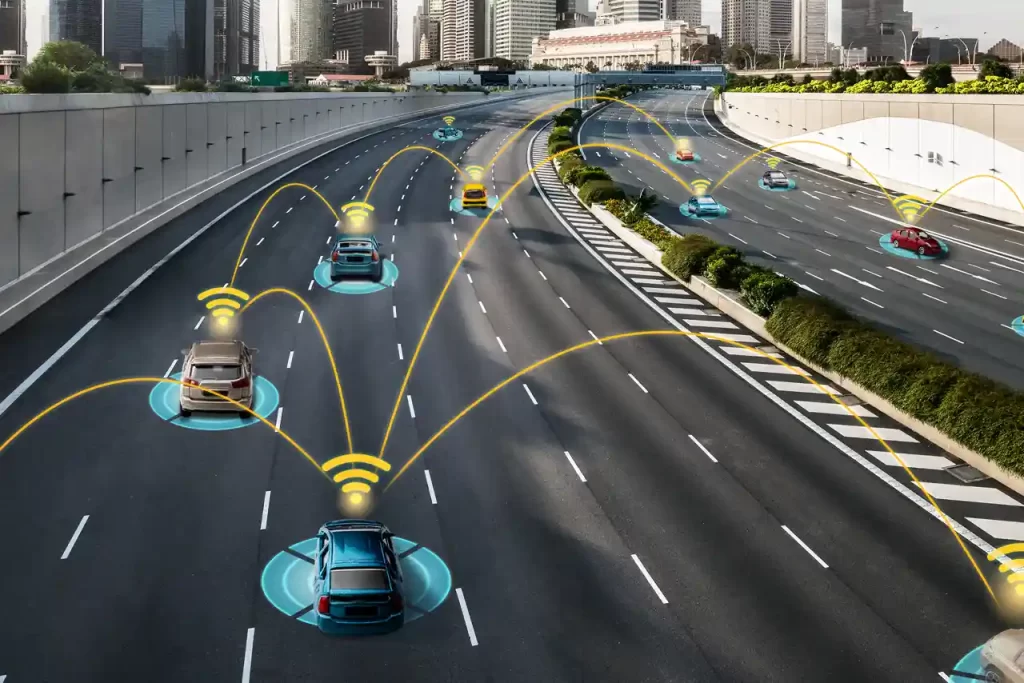

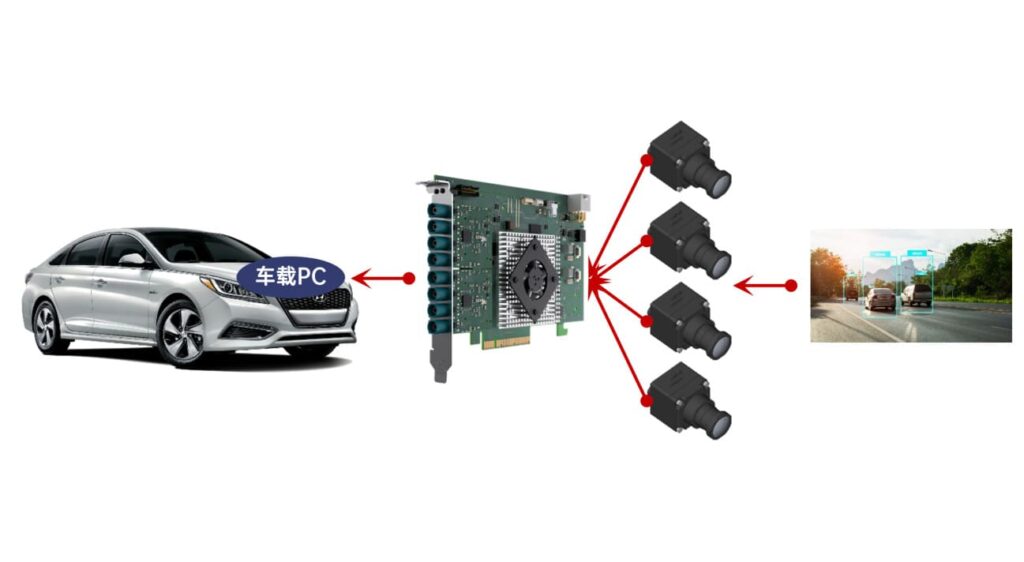

Multi-Channel In-Car Camera Raw Data Acquisition Solution

Capture multi-camera raw data accurately and synchronously during test drives in autonomous driving scenarios of smart cars and unmanned vehicles. proFRAME is compatible with a wide range of in-vehicle cameras based on SerDes protocols.

Record of driving scene in real car

With high-precision time-stamping (follow-up recharge/multi-sensor fusion time synchronization)

-1024x646.jpg)

Smart Driving Scene Injection Program (combined with TAP bypass function)

Can be injected while collecting, or previously collected real-vehicle road scenes or simulated scenes with high-precision timestamps can be injected accurately and synchronously, which can be used for in-vehicle DuT related testing and validation.

Recharge of real vehicles/simulated scenes

In-vehicle ECM/ECU performance/trigger/algorithm testing and validation

Product Composition and Core Strengths

Product component and core advantages

Modular Design

Flexibly configure video streaming data transmission for different serial deserialization protocols, and transmit/bypass video streaming data

Carries I2C/GPIO/PoC control signals for quick rollout to a wide range of industrial applications.

Camera Adapter Module camAD3

● Support SerDes protocols such as GMSL1/2/3, FPD-Link Ⅲ/IV, GVIF3, CSI-2, etc. (A-Phy, ASA-ML will be released soon).

● Provides four interfaces for connecting to camera, ECU or display with up to 10Gbit/s per channel.

● Optional video capture (4xIN) and video injection/bypass (2xIN, 2xOUT)

Optional Accessories

● Accessories: External Trigger Synchronization Kit to provide IN/OUT of the clock signal

● Applications: polyphase machine synchronization, external trigger synchronization, external sensor synchronization as main clock trigger

proFRAME 3.0 Baseboard

● Two interface slots for interchangeable camera adapter modules

Host Interface: PCIe gen3 x8 (~63 Gbit/s)

● More interface types: PCIe, CPCI-S, PXIe (coming soon)

FUJITSU FUJITSU, Software

● Windows/Linux compatible

One card with three integrated acquisition/injection/bypass functions

Application Scenarios

Application scenarios

proFRAME | Modular Smart Driver Video Capture & Injection Boss Card

- 8-Channel Video Data Acquisition

- 4-Channel Video Data Injection (Recharge)/Bypass

- ADAS/AD ECU Verification

- Hardness in the Loop (HiL) test

- Headlamp Verification, Display/Touch Screen Verification

- Camera Development

- R&D Platform for ISP Development

- End-of-Life (EoL) testing of in-vehicle display components

- For automotive/medical/industrial applications

In-vehicle Camera Raw Data Acquisition and Roadside Simulation Scene Reinjection

Real vehicle driving scene recording with high-precision time stamps (follow-up recharge/multi-sensor fusion time synchronization)

Real-vehicle simulation scene recharge, in-vehicle ECM/ECU performance/trigger/algorithm verification, in-vehicle (touch) Display test verification

Digital Microscope System

The system can help realize high-definition video capture and playback of tiny objects. Researchers in the fields of biology, medicine, and materials science can use proFRAME to observe microscopic structures, perform image analysis and measurements, and promote the progress of scientific research.

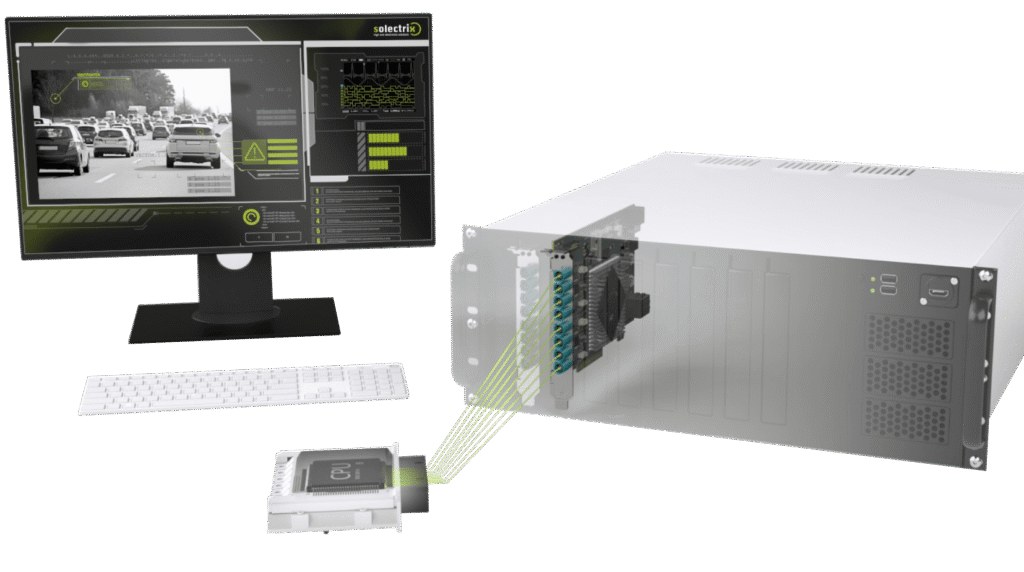

Hardware Loopback System (HiL)

Capture and process data using sensors, actuators and other hardware to realize system simulation.

Capture HD video data in real-time and synchronize with other systems to provide comprehensive data support for HiL testing.

EOL Testing

Used to inspect, collect and analyze product quality data on the production line. Through video capture and playback, it enables inspection and evaluation of product appearance, dimensions, manufacturing processes, etc. to ensure product compliance with standards. It can also help optimize production line efficiency and quality management.

Customer Examples

Application case

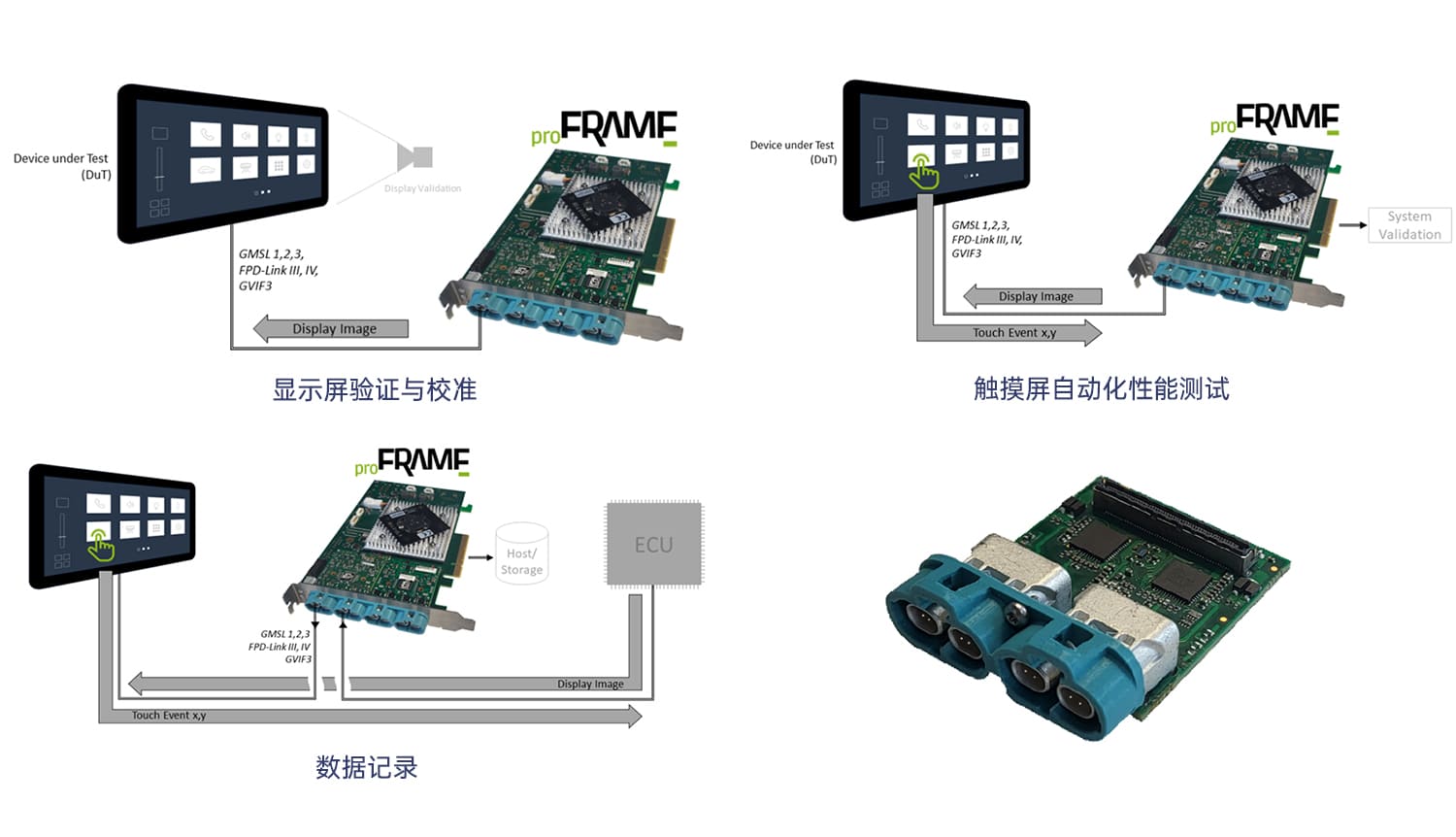

Display Verification and Calibration

Touch Screen Automation Performance Testing

Data Logging

Validation, Testing and Data Logging of Automotive Touch Panel Displays

Solution:proFRAME products with H-MTD® connectors are used for display calibration and verification. In these applications, video and control data are transmitted over shielded twisted pair (STP) cables for displays such as human-machine interface (HMI) displays, rear entertainment system displays and displays replacing conventional rearview mirrors.

Typical display applications:

(1) Display validation and calibration: Transfer of test images from a host system equipped with proFRAME (PCIe® or CompactPCI® serial port) to the display/device under test (DuT)

(2) Touch screen automation performance test: Capture the screen events through the return channel (I²C) and display its "touch".

"Playing the role of "relay station" for recording video streams and touch events

More partners and customers for proFRAME:

-1024x514.png)

Suitable for common car camera protocols

Synchronized capture of up to eight 4K video streams

Real-time high-speed acquisition of vehicle sensor data

Capturing multiple camera streams in a smart driving scene

Customer Needs:Advanced driver assistance systems (ADAS) such as traffic sign recognition, lane line recognition, parking assistance and autonomous driving (AD) functions require a large amount of real-time vehicle sensor data in order to operate, especially video data from embedded cameras (e.g. front-facing cameras or surround view systems). To validate these driving functions, driving scenes (data logging) must be recorded during the test drive, where video streams from each camera are captured synchronously, time-stamped and stored. These driving scenes are then played back into the validation ADAS/AD ECU during a hardware-in-the-loop (HiL) test to verify proper function based on real sensor data.

Solution: Solectrix offers high-performance modular video capture and injection boss cards that support most common automotive cameras based on GMSL™ and FPD-Link™ and have been successfully used for many years in a wide range of data recording equipment. The latest generation of proFRAME 3.0 offers two slots for camera adapters up to 40 Gbit/s (camAD3) and supports the latest technologies such as GMSL™3 and FPD-Link™ IV. proFRAME 3.0 can capture up to eight simultaneous 4K video streams, including control signals (I²C). The time stamping of incoming data is handled with high precision by the hardware and can be synchronized with other capture devices via an external trigger cable. The camera can be supplied with configurable voltage via a coaxial cable (PoC).

Precise and synchronized playback of the driving scene

Common adapters for adapters are available.

Synchronized capture of up to eight 4K video streams

ADAS/AD validation through hardware-in-the-loop testing

Customer Needs:In a hardware-in-the-loop test for Advanced Driver Assistance System (ADAS) or Automated Driving (AD) functionality, the corresponding ADAS/AD Embedded Control Unit (ECU) receives driving scenes in the form of video streams, which are pre-collected during the test drive. In order to validate the ADAS/AD functionality, it is critical to accurately play back each video frame according to the timestamp given during the capture.

Solution: proFRAME is a high-performance video capture and playback system ideally suited for precise synchronized playback of driving scenes in HiL systems to validate ADAS/AD embedded control units. Several different camera adapters (camAD3) support the playback of video streams using most serializers (GMSL, FPD-Link) commonly found in the automotive market. The latest generation of proFRAME 3.0 offers two slots for camera adapters (camAD3) up to 40 Gbit/s and supports the latest technologies such as GMSL™3 and FPD-Link™ IV. proFRAME 3.0 can capture up to eight simultaneous 4K video streams, including control signals (I²C). Playback can be processed based on timestamp information or external triggers for each video frame.

Precise and synchronized playback of the driving scene

Common adapters for adapters are available.

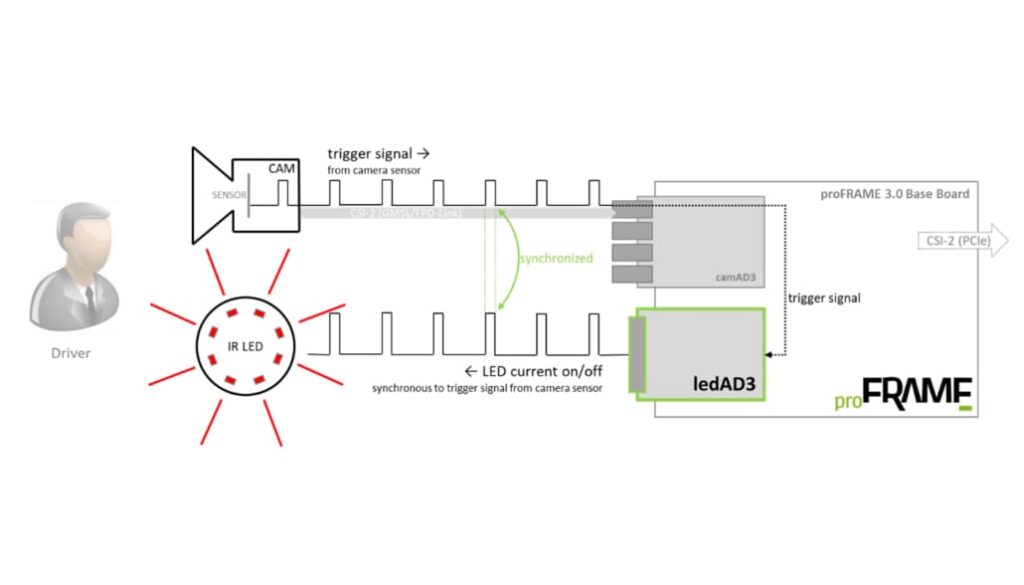

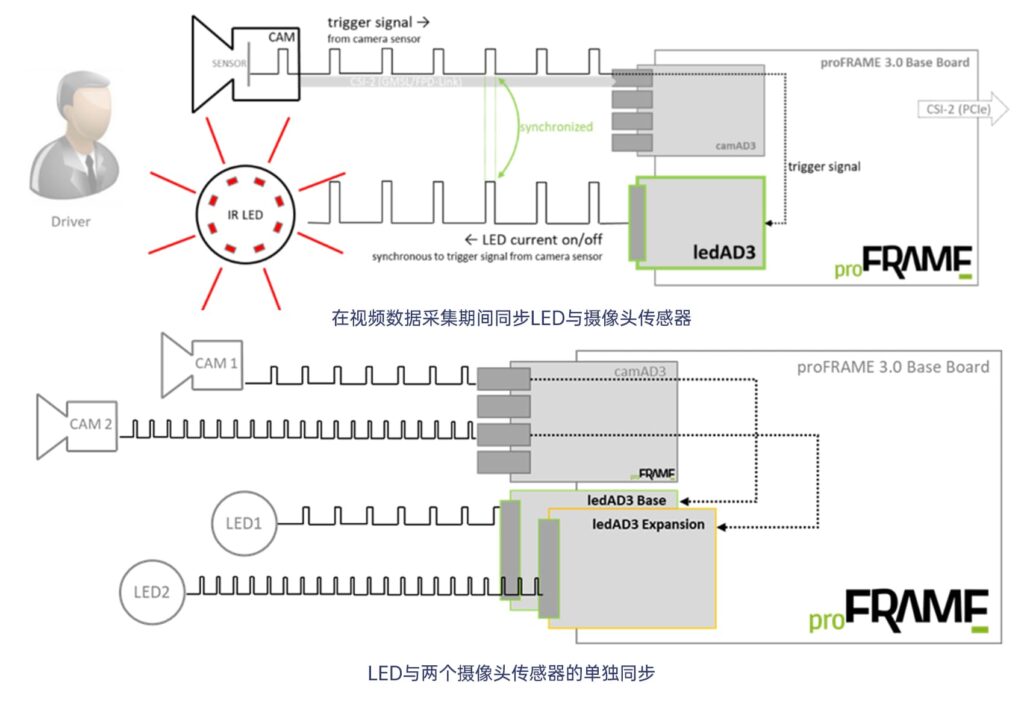

Provide ledAD3 expansion module

Vehicle internal monitoring system validation

Solution:Nowadays, it is a legal requirement in the EU that new vehicles must be equipped with a fatigue warning system. With the necessary accessories, proFRAME can be used for the development and validation of such systems.

The new LED driver adapter ledAD3 provides the user with the means to control single or multiple LEDs, e.g. to illuminate the interior of a vehicle using infrared (IR) LEDs synchronized with the exposure of a camera sensor. The LED driver adapter can be connected directly to the proFRAME 3.0 baseboard in the same way as the camAD3 camera adapter. The LEDs to be synchronized are connected to the ledAD3 via the included connector. The LED Driver Adapter supplies power to the LEDs via an adjustable constant current source, the output of which is controlled by a trigger signal from the camera sensor, which is connected to the camera adapter on the same proFRAME 3.0 baseboard.

We also offer the ledAD3 expansion module for controlling additional LEDs that are switched in synchronization with the second camera trigger signal. The ledAD3 expansion module can be connected directly to the ledAD3 base module, so it does not take up an additional slot on the proFRAME 3.0 baseboard. Thus, a complete system consists of a proFRAME 3.0 baseboard, a camAD3 camera adapter, a ledAD3 base module, and the optional ledAD expansion module. With this system, LEDs can be synchronized with one or two cameras.

More Products

Related product

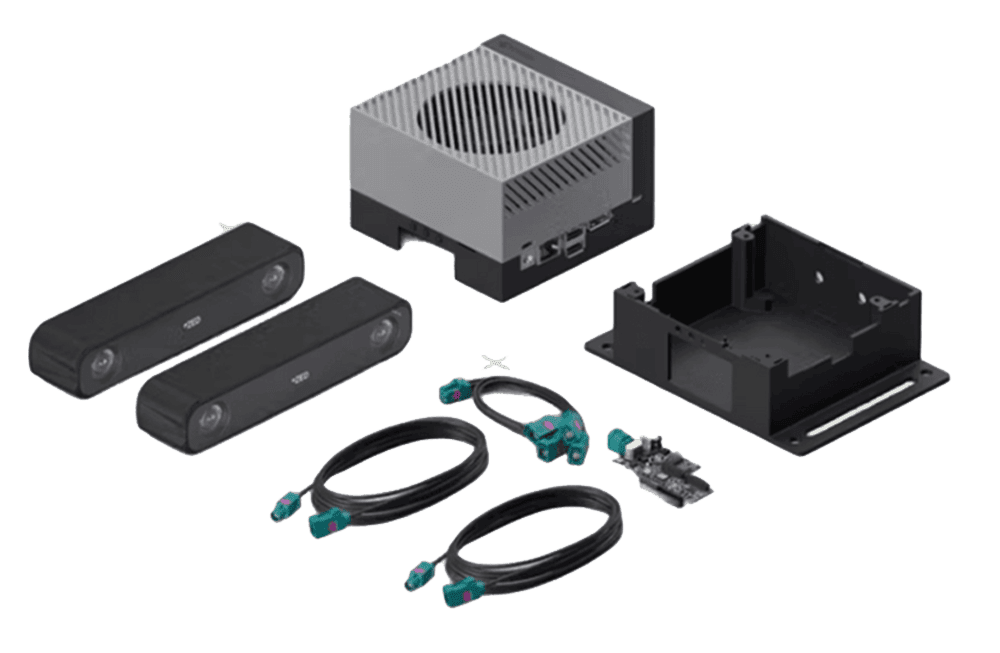

Stereolabs ZED Automotive Camera

Capture rich spatial perceptions in dynamic scenes

Includes Monocular Camera, Dual Vision Camera, Matching SKD, GMSL2 Capture Card and All-in-One Kit

Stereolabs ZED Edge Calculator

Powerful embedded micro pc

Easy and seamless processing of real-time video streams with edge AI and robotics technologies

Door Vision Camera System

Clear all-weather imaging at night and in rain, fog and snow

Suitable for low visibility and all-weather surveillance as well as autonomous driving and smart city applications.

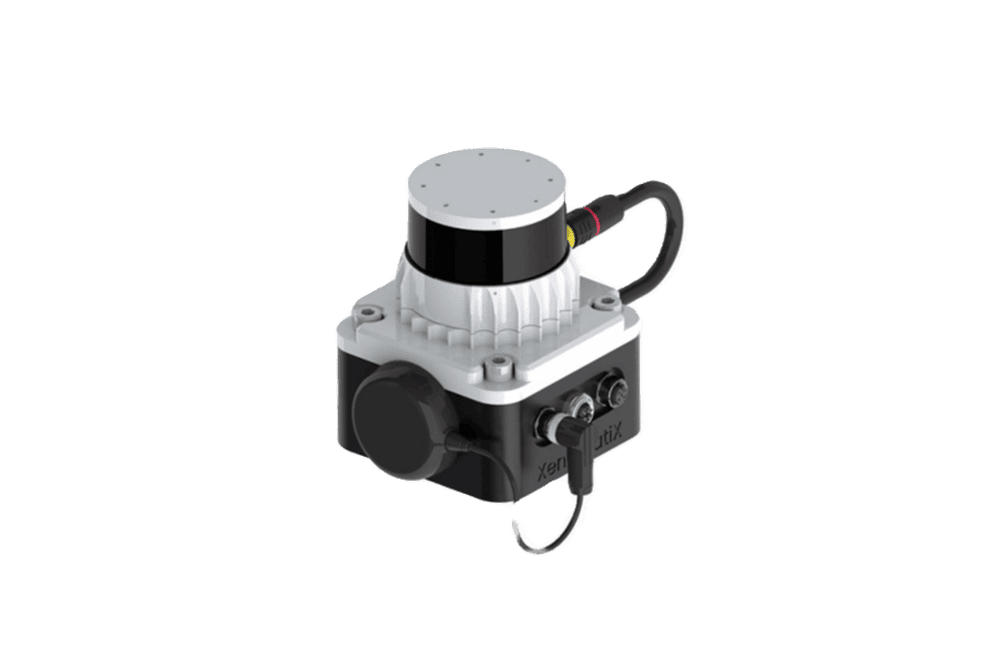

Vehicle Mounted Mapping System GPC360

Laser radar system with integrated GNSS technology

Collects detailed 3D information from mobile vehicles in geospatial data, such as precise location, dimensions and surrounding relationships

Professional technical support from HONGKEI to help you succeed in your project.

As a provider specializing in machine vision and optoelectronic inspection solutions, Avision is also committed to providing you with a range of paid technical services related to this product, aiming to help you succeed in your project in the most cost-effective way. Please contact us if you need technical services related to this product!