- Home

- Technical Products

Enterprise Cloud IT Solutions

Test Measurement

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Latest Articles

- About Us

EN

EN

PCIE Image Capture Card

Provides FPGA accelerator cards with various interfaces such as GigE Vison, Cameralink, Coaxpress, etc., which are highly compatible and widely used in real-time, high-bandwidth visualization and image processing applications.

- High reliability, using the powerful Arria 10 FPGA, with large-capacity memory, high-bandwidth data transmission channels and rich I/O interfaces, to ensure 100% frame capture.

- Based on the IP development function of FPGA, real-time compression of incoming images/videos reduces the storage space required for image acquisition, reduces bandwidth requirements and increases transmission rates.

- Provides the ProcVision suite, including development tools, data compression and management IP, and OpenCL support to help users easily customize and develop image processing applications.

Selecting the right PCIE frame grabber for your project

Gidel, our partner, has a wide range of product models, and is the cornerstone of our technology.

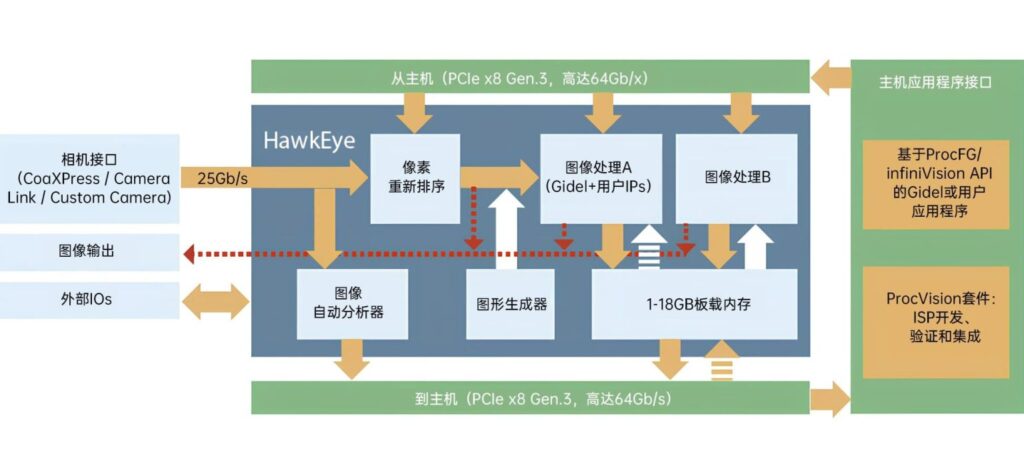

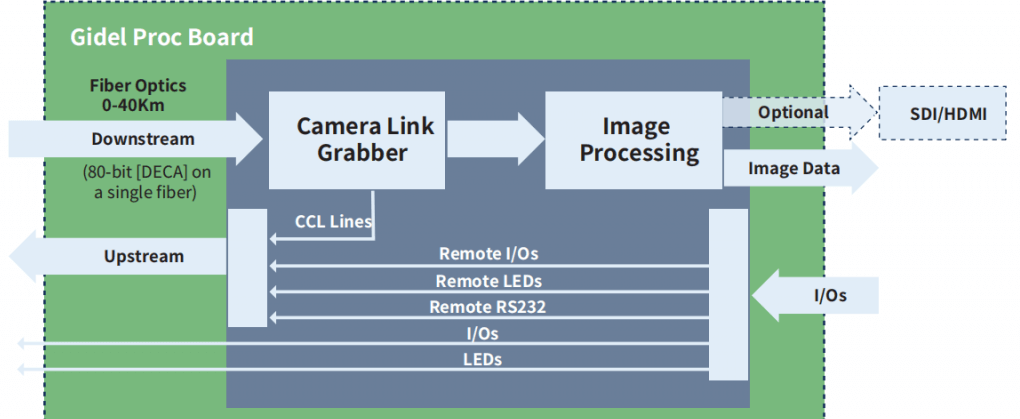

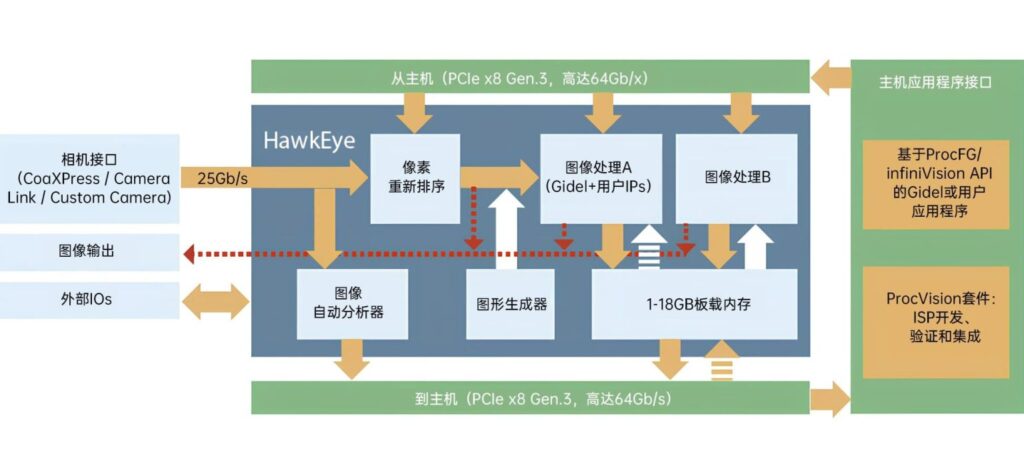

HawkEye-CL

- Compatible with Camera Link version 2.0, Camera Link modes: Basic/Medium/Full/80-bit (Deca), option for connecting 2 basic cameras

- Huge frame buffer of up to 16 GB for high capture capacity and enhanced image processing

- Ultra-high data offload capability via PCIe Gen. 3 x8 for high-resolution post-processing on hosts

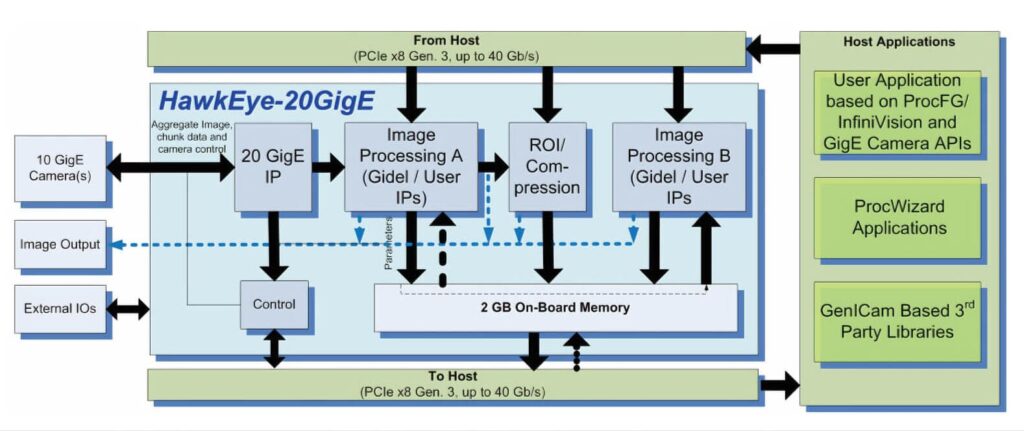

HawkEye- 20GigE Image Capture Card Dual-Port 10gb Frame Capture and Image Processing System

- Grabbing from 2 x 10 GigE Links, Multi-Phase Support, Link Aggregation Support, PCIe x8 3rd Generation

- Acquisition bandwidth up to 20Gb/s via 2 SFP+ ports (copper/fiber), low power consumption

- Realizes 100% without frame loss, CPU-less data offload via PCIe Gen.3 x8, high-resolution post-processing on the host.

Proc1C10M Ultra-High Performance Real-Time Processing Stratix 10 MX HBM2

- FPGA modules to be used with other boards

- Capture from 4 × 100GigE links, support for multiple cameras, support for link aggregation

- No frame loss, support ROI acquisition, acquisition bandwidth up to 400gb /s.

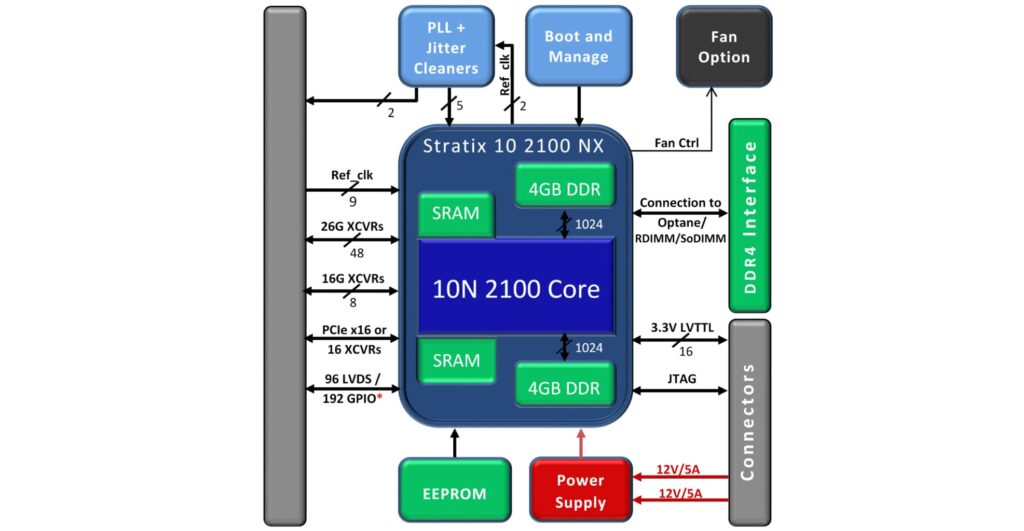

Proc1C10N Ultra-High Performance Stratix 10 NX HBM2 for Real-Time AI Processing

- FPGA modules to be used with other boards

- Capture from 4 × 100GigE links, support for multiple cameras, support for link aggregation

- No frame loss, support ROI acquisition, acquisition bandwidth up to 400gb /s.

HawkEye-CXP12 Frame Grabber and Image Processing System

- Grabbing from up to 4 cXp cameras via 4 cXp-12/6 links

- Supports CoaXPress 2.0 capture, bandwidth up to 50gb/s, host interface: PCIe Gen. 3x8

- Huge frame buffer of up to 16GB for high capture capacity and enhanced image processing

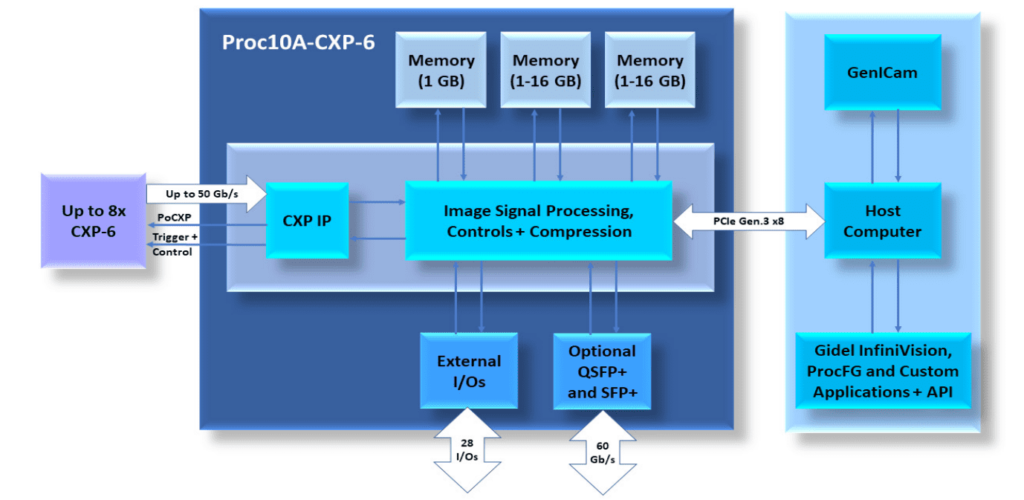

Proc10A-CXP-6 High Bandwidth CoaXPress Capture and Image Processing

- FPGA modules to be used with other boards

- Grab up to 8 CoaXPress cameras from 8 CXP-6 links, Host Interface: PCIe Gen. 3x8

- CoaXPress 1.1 support, capture bandwidth up to 5gb/s, huge frame buffer (up to 32 GB)

Application Scenarios

Focusing on the vision field, covering a wide range of industries; based on application scenarios, to solve the needs of the sub-segments. We can also customize an integrated solution for your project, please contact us for more information.

Industrial Inspection and Automation

PCIE video capture cards are used for real-time image processing and analysis in industrial production, such as defect detection, product sequencing and quality control projects, and can also be used to monitor and adjust the operation status of machines to improve production efficiency and product quality. It can also be integrated into automation systems for machine vision guidance, identification and tracking.

Vehicle and Application Inspection

Automotive and application inspections require real-time analysis and system response. PCIE adapters can be used to detect defects in parts and components to ensure the safety and quality of automobiles, for environmental awareness and obstacle detection in intelligent driving systems. They can also be used for data collection and analysis during vehicle testing and inspection.

Military and Aerospace

Military and aerospace aerospace applications combine real-time and post-acquisition analysis. PCIE capture cards can be used for image acquisition and processing of equipment and devices such as drones and aircraft, such as navigation, target identification and tracking. In military intelligence gathering and reconnaissance, it is used for real-time image analysis and intelligence processing.

Medicine and Life Sciences

PCIE capture cards are important for medical and scientific research applications that require high-resolution imaging capabilities for high-precision image reconstruction and analysis, such as for medical imaging diagnostics, such as image processing and analysis of CT, MRI and ultrasound images; and for data acquisition and control of laboratory equipment and scientific instruments. In biomedical research, it is used in cellular imaging, brain imaging and gene sequencing analysis.

High-end Machine Vision

PCIE image acquisition cards can be integrated into high-end machine vision systems, providing powerful support for high-precision, high-speed target detection and image processing to meet the needs of automated production lines and high-tech manufacturing processes. For example, in robotics and automated navigation systems, it is used for environment sensing and target recognition. Face recognition and behavior analysis in intelligent surveillance and security systems. For image processing and rendering in virtual reality and augmented reality applications.

High-end Machine Vision

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradisematic country, in which roasted parts of sentences fly into your mouth. It is a paradisematic country, in which roasted parts of sentences fly into your mouth. Even the all-powerful Pointing has no control about the blind texts it is an almost orthographic life One day however a small line of blind text by the name of Lorem Ipsilon has no control over the blind texts. One day however a small line of blind text by the name of Lorem Ipsum decided to leave for the far World of Grammar. The Big Oxmox advised her not to do so, because

- Phone:+1 (859) 254-6589

- Email:info@example.com

Broadcasting and Live Streaming

PCIE image acquisition cards can be integrated into high-end machine vision systems, providing powerful support for high-precision, high-speed target detection and image processing to meet the needs of automated production lines and high-tech manufacturing processes. For example, in robotics and automated navigation systems, it is used for environment sensing and target recognition. Face recognition and behavior analysis in intelligent surveillance and security systems. For image processing and rendering in virtual reality and augmented reality applications.

Broadcasting and Live Streaming

A small river named Duden flows by their place and supplies it with the necessary regelialia. It is a paradisematic country, in which roasted parts of sentences fly into your mouth. It is a paradisematic country, in which roasted parts of sentences fly into your mouth. Even the all-powerful Pointing has no control about the blind texts it is an almost orthographic life One day however a small line of blind text by the name of Lorem Ipsilon has no control over the blind texts. One day however a small line of blind text by the name of Lorem Ipsum decided to leave for the far World of Grammar. The Big Oxmox advised her not to do so, because

- Phone:+1 (859) 254-6589

- Email:info@example.com

Machine Vision Imaging Solution with High Accuracy and Cost Effectiveness

Outstanding, no fear of comparison! Six core advantages, leading machine vision first!

Multi-protocol support and compatibility

Supports interface protocols such as CameraLink, CoaXPress, GigE Vision, etc.

Real-time high-bandwidth image acquisition

Wide bandwidth coverage, support 1Gbps~50Gbps acquisition bandwidth

zero CPU utilization

PCIe Gen. 3×8 enables cpu-less data offloading and high-resolution post-processing on the host.

Optional capture paths

Supports ROI acquisition and multi-phase machine image acquisition

Image Compression

Supports JPEG, lossless compression and patented Quality+ compression.

Customizable image capture process

Rapid development of user's own image processing IP based on on-board FPGA resources

Technical Support

Professional technical team to serve you: with many years of experience in machine vision and optoelectronic inspection, customized a number of rich and mature landing projects.

As a provider specializing in machine vision and optoelectronic inspection solutions, Avision is also committed to providing you with a range of paid technical services related to this product, aiming to help you succeed in your project in the most cost-effective way. Please contact us if you need technical services related to this product!

Frequently Asked Questions

Technical support and paid services to drive your project to the limit.

Compared with the competitors, our video capture cards have the following significant advantages:

1. High-performance FPGA acceleration

2. excellent flexibility and programmability

3. low latency data processing

4. Easily expandable functions

5. Powerful high-resolution support

6. Multi-channel and multi-mode operation capability

7. Comprehensive software support and development tools

- CameraLink, up to 25Gb/s bandwidth, supports Camera Link modes: base,medium,full,deca.

- CoaXPress, up to 4*12.5 Gb/s bandwidth from up to 4 CXP interfaces via 4 CXP-12/6 connections.

- GigE Vision, with an aggregate bandwidth of up to 2*10Gb/s.

The video capture card is built with Intel Arris 10 series chipset and Quartus II compiler software.

In practice, the I/O interfaces are the same for Rev.1, Rev.2, Rev.3, and future Rev.4 versions, and the software manuals are incorrectly describing the corresponding locations. These versions of HawkEye all utilize the same I/O interface configuration and there is no difference.

The FPGA (Field Programmable Gateway Array) on the video capture card is capable of performing various functions including image pre-processing, data processing, data transfer, and control. Below are some common image pre-processing operations:

1. Image Filtering

2. Image Enhancement

3. Image Cropping and Scaling

4. Graphical alignment

5. Compression and Coding

6. Frame synchronization and timestamp generation

Supported pixel formats: Monor, Bayer, RGBA and RGB, etc. Capture cards are usually developed according to different capture protocols (e.g. CameraLink, CoaXPress and GigE Vision) to support cameras compatible with the corresponding protocols.

Machine vision and industrial automation:

(1) For visual inspection and quality control tasks on automated production lines.

(2) Can be used in semiconductor manufacturing, electronic assembly and automotive industries.

Example: Detecting product surface defects, measuring object size and shape.

(3) Medical imaging:

Used in medical imaging equipment such as MRI, CT scanners and ultrasound equipment.

(4) Supporting physicians in the acquisition and processing of medical images.

Example: Image reconstruction and analysis to aid in diagnosis.

(5) Energy:

Data acquisition and analysis for the energy sector.

(6) Support for oilfield exploration and power system monitoring.

Examples: seismic data processing, power network optimization.

[Hardware Support]

(1) Provide high quality image capture card hardware, selected and configured according to customer's needs and applications.

(2) Ensure the performance and stability of the collector card to meet the requirements of the specific application.

Software drivers and tools:

(3) Provide corresponding software drivers to ensure the compatibility of the capture card with the operating system and applications.

(4) Software development tools, APIs and sample code may be provided to assist customers in customized application development.

Technical Support:

(5) Provide technical support team to resolve hardware and software issues.

(6) Online documentation, user manuals, and knowledge bases may be available to assist customers in the use and maintenance of the capture card.

[Customized Solutions

(1) Provide customized hardware and software solutions based on specific customer needs.

(2) We can work with our customers to design a collector card and supporting system that meets their application needs.

[Training and Counseling]

(1) Training courses may be provided to help customers better understand how to use and configure their capture cards.

(2) Consulting services may be available to assist customers in selecting the hardware and software configuration best suited to their application.

Updating and Maintenance:

(3) Provide firmware and driver updates to ensure the performance and security of the card.

(4) Maintenance contracts may be offered to ensure the long-term reliability of the cards.