- Home

- Technical Products

Enterprise Cloud IT Solutions

Test Measurement

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Resource Center

- About Us

EN

EN

MES Manufacturing Execution System

What is MES software?

Manufacturing Execution System (MES), also known as production monitoring software - is a core IT solution in an enterprise's information architecture. It significantly enhances the visibility of manufacturing processes and enables precise optimization of industrial workflows through real-time capture of full-process production data. As a mission-critical decision-support platform, MES is a core driver for continuous process improvement strategies.

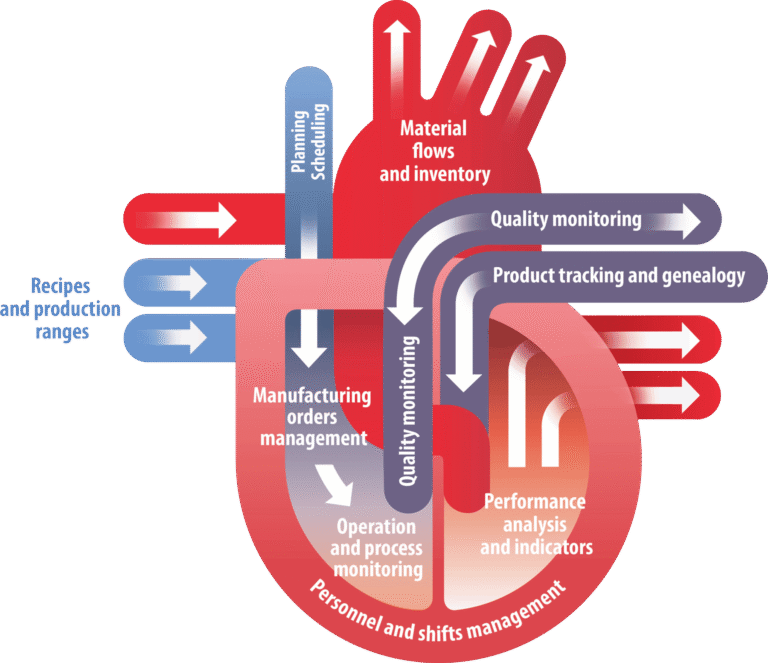

COOX: The Heart of Industry 4.0

COOX MES (Manufacturing Operations Management System) is the core solution for the Smart Factory. The software is able to control and optimize the entire process from the receipt of production orders from the ERP or management system to the warehousing and shipment of products. Through seamless integration with the ERP system, COOX (Collaborative Operations and Execution System) captures all production data in real time, providing manufacturers with a panoramic view of production monitoring.

Based on the in-depth analysis of these data, enterprises can continuously improve equipment performance, proactively prevent production interruptions and unexpected risks, and realize the transformation from reactive to proactive management. With innovative modeling technology, COOX MES software can be adapted to various industrial processes and equipment configuration scenarios. Its modular modeling system (covering models of equipment, processes, etc.) supports cross-factory reuse, a feature that ensures both deployment efficiency and application system robustness.

With the COOX MES platform and its MESbox module set, you can realize real-time production control at your industrial site at the hub level. This mature and advanced solution features rapid deployment to help you optimize your operational processes, increase production efficiency, and effectively reduce costs!

- Modularized integration solutions, expandable on demand

- Perfectly adapted to all types of manual/automated processes by means of dynamic modeling technology.

- Realize the systematic traceability of the whole process and material flow.

- Easy and efficient deployment based on secure web architecture

- Supports flexible deployment from stand-alone equipment to complete plants to multi-sites

COOX MES software brings you the following benefits

Project Director>

- Real-time data updates (unlike ERP)

- Real-time visualization of production results against target values.

- Calculate the actual cost of the product on the spot

- Ensure the absolute credibility of report data transmission

Production Manager

- Real-time calibration of target achievement rate

- Intelligent Identification of Manpower Requirements to Secure Program Capacity

- Precise visualization of the status of personnel on duty during abnormal production.

- Strictly ensure order delivery fulfillment

Operator>

- View job progress in real time

- Precise guidance on tasks to be performed

- Easy access to necessary documents

- Save time filling out worksheets

- Instruction in fine-tuning

Quality Manager

- Compliance with regulatory requirements

- Continuous optimization of quality indicators

- Customized Adaptation

- Strict adherence to standardized processes

Maintenance Manager>

- Accurate statistics on equipment failure frequency and downtime.

- Reducing high loss failures

- Scheduling maintenance downtime at appropriate times

- Emergency Response Team Status Confirmation

Director of Procurement>

- Real-time inventory visualization

- Understand the reason for discontinuation immediately

- Accurately obtain the delivery quantity of the last order.

- Accurate indication of the order date for the next production run

- Quick Response to Provider Delays

COOX MES Software Realization Core Functions

Performance Analysis - Indicators - OEE - KPIs

Quality and industrial performance are the core elements for the continuous improvement of production processes (following the TPM methodology: Toal Productive Management). OEE calculation of key performance indicators and visualization of dynamic real-time charts.

Product Quality Control

Quality, as a core element of production control, is a horizontal control function for the entire process from incoming raw materials to product delivery. Includes multiple levels of quality control and real-time performance improvement.

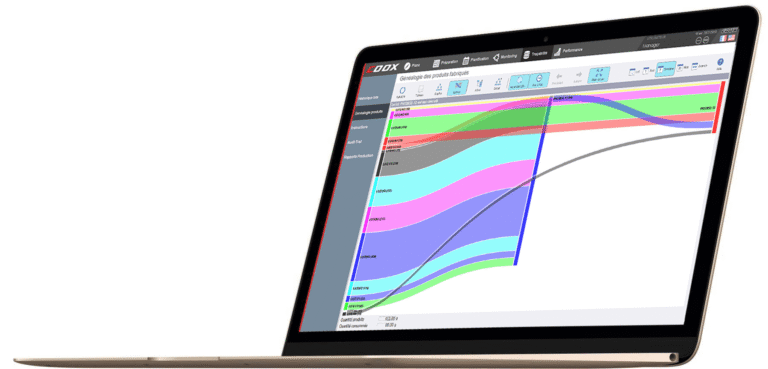

Product Traceability System - Spectrum Management

In order to safeguard product quality and meet increasingly stringent regulatory requirements, companies must establish effective product traceability mechanisms. This includes container and transfer process modeling, systematic material flow tracking and a complete profile of batch and equipment usage.

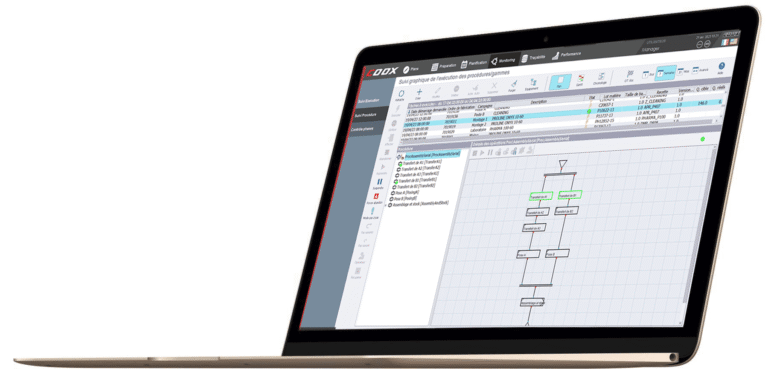

Operating Procedure Monitoring - Process Traceability - Batch Files

As the core of production efficiency and quality, process control has become a key issue for all industries. This includes process control, full process traceability and electronic batch files.

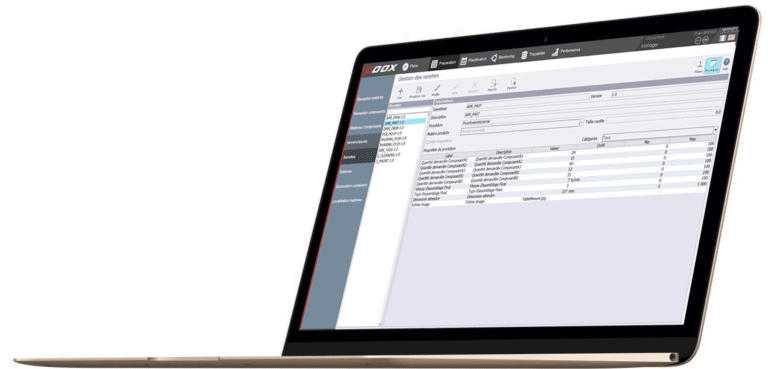

Recipe and bill of material management

Product definitions are the basis for production control and execution. These definitions can be sent from your ERP system, but are usually created or refined in the MES. This includes recipe definitions, process modeling, recipes and multi-step programs.

Production Order Management

The Production Order System sequences the manufacturing process according to the orders to be delivered. Includes automated management of importing orders from ERP, initiating and monitoring production orders and resource allocation.

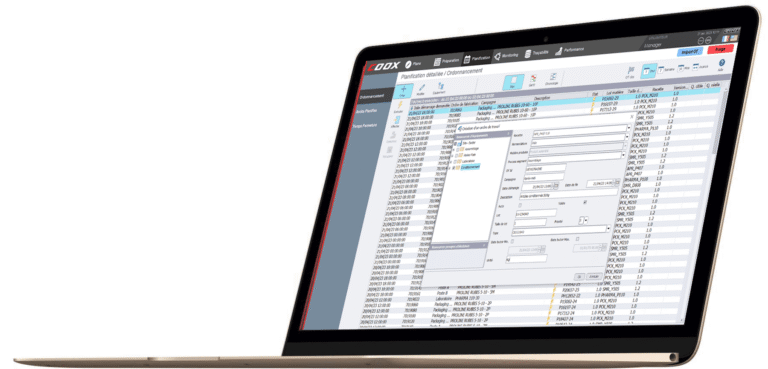

Production Planning and Scheduling - Detailed Planning

Production orders can be transferred from ERP or production management systems to MES software or can be created directly. Functions include: intelligent scheduling of production orders, control of order fulfillment, and real-time visualization of production stages.

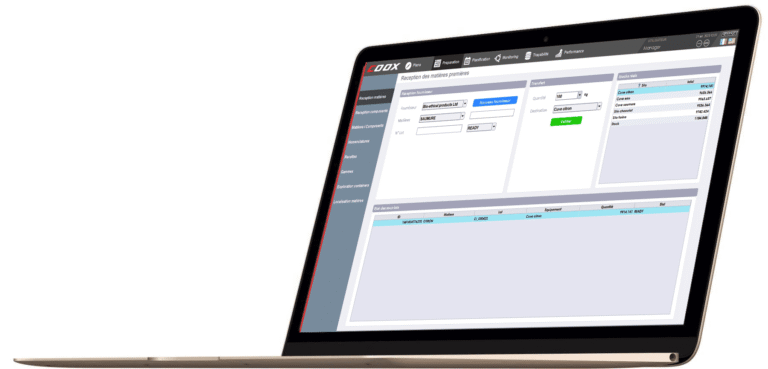

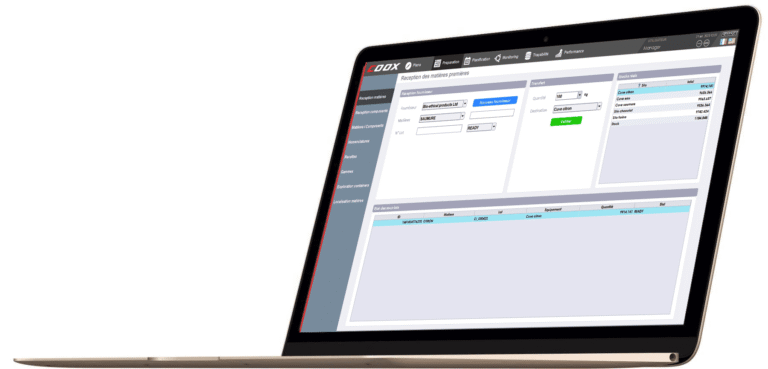

Material Flow and Inventory Management

Realize the visual management of the whole process of raw materials/finished products, including comprehensive tracking of batches, real-time identification of batch location, and optimization of inventory management.

People and Team Resource Management

Production monitoring/MES functions do not replace personnel management, but rather provide decision support for workstation labor deployment. This includes efficient allocation of human resources, control of operation execution time and optimization of actual product manufacturing costs.