- Home

- Technical Products

Enterprise Cloud IT Solutions

Test Measurement

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Latest Articles

- About Us

EN

EN

What is MES software?

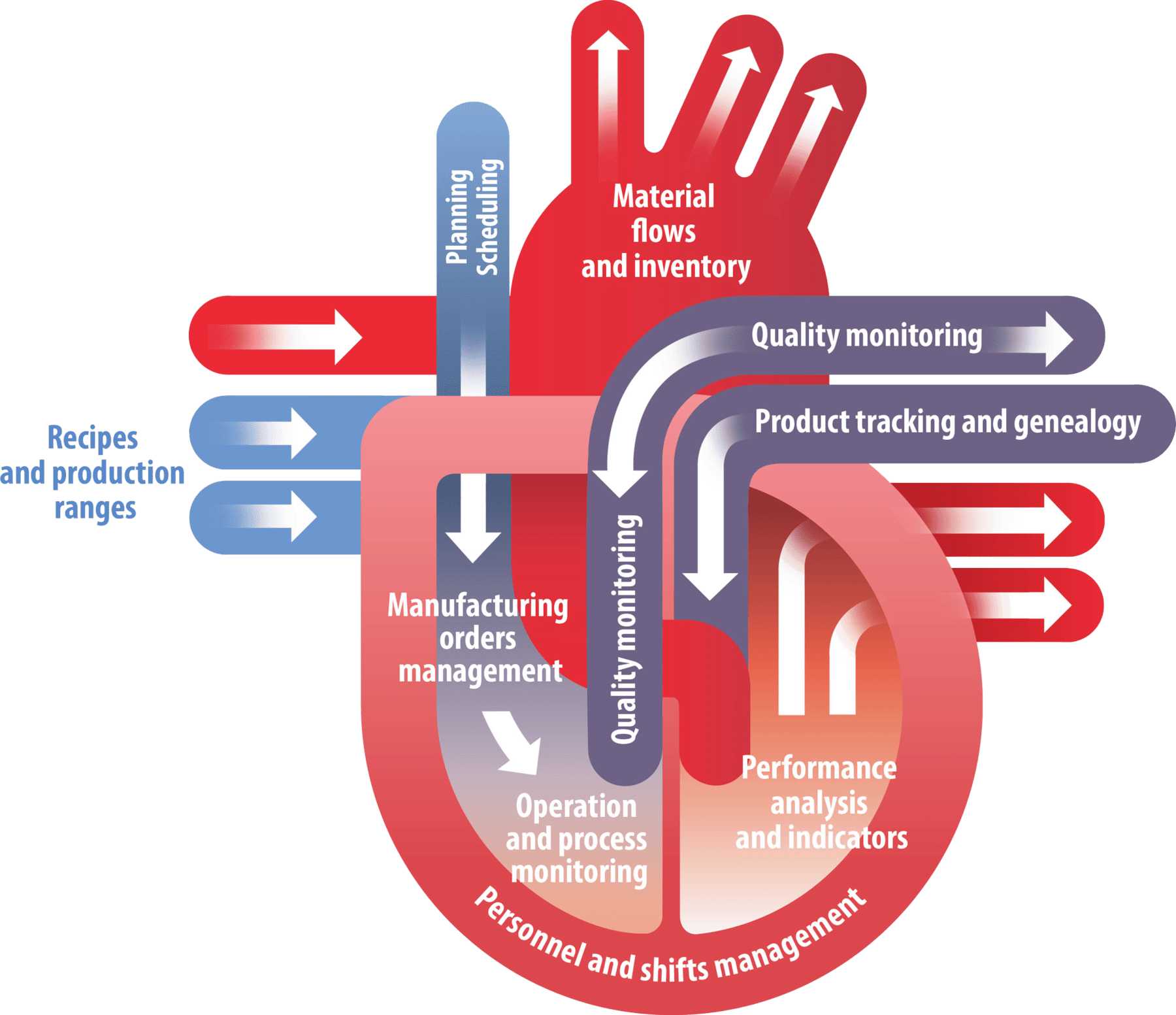

MES (Manufacturing Execution System,Manufacturing Execution SystemThe software enables more effective control and tracking of the production process by collecting all production data in real time. It provides managers and operators with all the information and instructions necessary to ensure that production runs smoothly from the time a manufacturing order is placed to the completion of the finished product. The software plays an important role in continuous production improvement by tracking all the information needed to meet quality requirements and identify sources of production optimization.

The SA-95 study provides further insight into the services that must be provided by an MES solution and emphasizes the system perspective. While different MES functions can be implemented incrementally, they are not independent of each other and need to share a lot of information.

Resource Management

Production Scheduling

Product and Lot Path Planning

Document management

Data Collection and Sourcing

Staff Management

Quality Management

process management

Maintenance Management

Product Traceability and Product Genealogy

Performance Analysis

What information does MES provide?

Below are a few simple cases, from different perspectives, more intuitively demonstrates the value of MES in practical applications.

Analyze and improve production performance

- How does my line perform in terms of OEE (Overall Equipment Effectiveness)?

- What are the reasons that affect performance variance, quality compliance, or major types of downtime?

- How much productivity have we lost on Line 4 due to equipment adjustments?

- Is the morning shift more productive than the evening shift? What are the reasons?

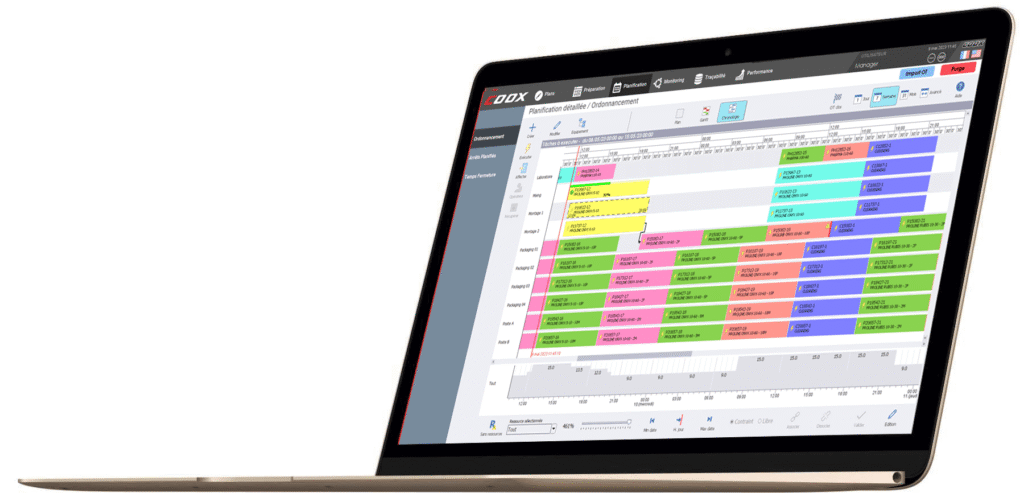

Optimization of production plan

- Will we be able to deliver orders on time even though one of our production lines is down for maintenance?

- Can promotional products be produced in advance or in sync with tomorrow morning's scheduled orders?

- Can we still deliver order CC5678 on time due to equipment failure that caused a delay in the production line?

| Analyze Product Quality

- An entire shipment of machine parts was returned by a customer. Did we fail to ensure dimensional compliance before delivery?

- Was the equipment used for product formulation cleaned as required on September 13?

- Does my production meet the latest regulatory requirements?

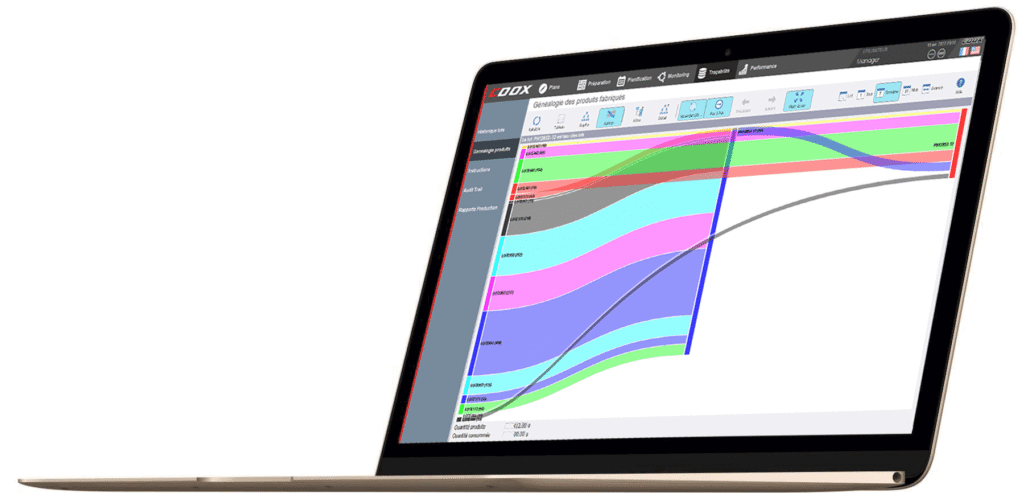

| Improve production traceability

- What is the actual sugar distribution ratio for Organic Lot LL876?

- From which supplier did the coloring used in the Yogurt that failed the quality test come from?

- Has the maintenance status of Cold Storage No. 3 affected the production target?

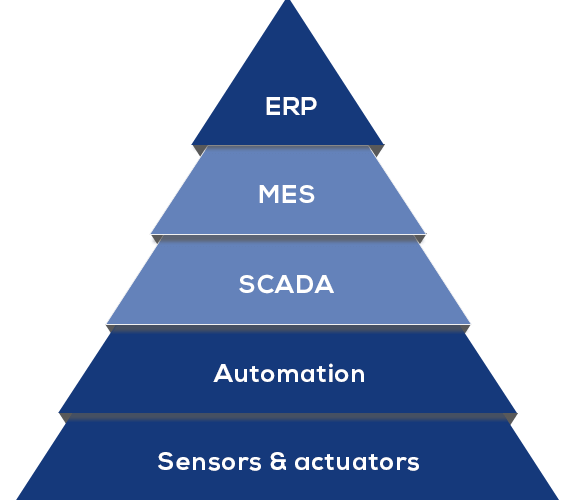

MES Positioning in Information Systems

SCADA (Supervisory Control and Data Acquisition) SoftwareThe main function of a PLC (Programmable Logic Controller) is to enable communication between the PLC (Programmable Logic Controller) and plant equipment to enhance control of production. The core function of management software (especially ERP - Enterprise Resource Planning) is to manage resources and help manufacturers optimize organizational operations.

For a long time, there has been a large gap between the two, and there is an urgent need to develop specialized solutions to "bridge the gap" and allow the two systems to interface smoothly.

MES (Manufacturing Execution System) is the missing link that ensures a seamless interface between ERP data and factory floor operations.

To this end, MES is responsible for centralizing and coordinating all production data, providing manufacturers with real-time, accurate key data that enables them to respond quickly to market demands and industry developments while ensuring compliance.

MES software empowers manufacturing enterprises with greater flexibility and agility, enabling them to stay ahead of the competition, precisely control production processes, and achieve high standards of industrial performance. In addition, MES optimizes production processes, inventory management, and manufacturing procedures to improve product quality, operational efficiency, and overall productivity.

Professional technical support from HONGKEI to help you succeed in your project.

As a provider specializing in machine vision and optoelectronic inspection solutions, Avision is also committed to providing you with a range of paid technical services related to this product, aiming to help you succeed in your project in the most cost-effective way. Please contact us if you need technical services related to this product!