- Home

- Technical Products

Enterprise Cloud IT Solutions

Test Measurement

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Latest Articles

- About Us

EN

EN

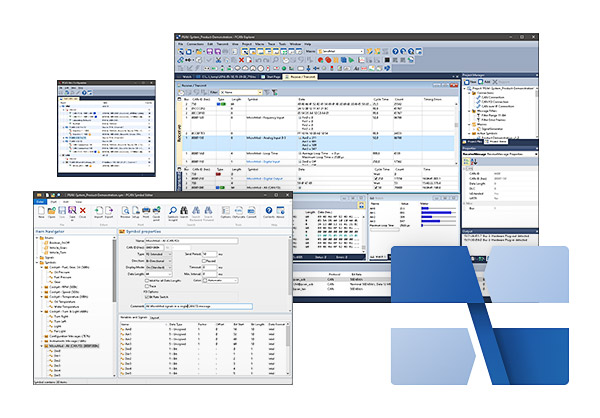

PCAN-Explorer 6: CAN Bus Analyzer

Comprehensive and versatile CAN (FD) bus communication analysis software that supports bus monitoring, manual or periodic packet sending, function plug-ins, and built-in scripts for bus node control or simulation.

- Bus Full Process Analysis

- Newspaper replay

- Database Analysis

- UI Visualization Design

- virtual channel

- VBS Script

- Multi-project management

- Required for use with HTC CAN hardware products.

Advantages

Manage all the settings, information and documents in your project.

Export entire projects (including linked files) to a convenient package for archiving or sharing

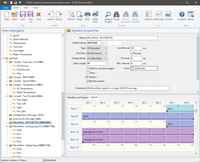

Extensive revisions to the user interface have improved the dialog boxes for setting up transmission messages and managing signals.

Support for automatic notification of new software versions and the update process.

Integrated text editor with syntax highlighting for creating and editing symbol files, macros and VBScript

User interface language can be switched

(German/English)

Integration of plug-ins to upgrade functionality

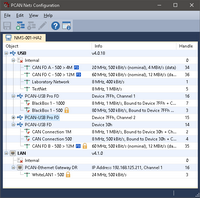

Connecting CAN and CAN FD

- Up to 16 CAN channels

- Simultaneous use of multiple PEAK CAN interfaces, regardless of hardware type

- Supports CAN Specification 2.0 A/B and FD

- CAN bit rate (nominal) up to 1 Mbit/s

- Data bit rates up to 12 Mbit/s (CAN FD interface only)

- Optional use of custom bit rates

- Listen-only mode can be activated.

- Clear overview of the connection and its bit rates, status, error counters and bus loading

- Functions to Perform CAN Controller Hardware Reset

Transmission and reception

- CAN data traffic in the form of sortable receive and transmit lists with configurable column displays

- Display messages showing ID, length, data byte, timeout, number of received messages, and receive interval.

- The display of error frames can be activated for each connection.

- CAN ID in hexadecimal or decimal format

- Display of reception, transmission and error statuses

- Maximum resolution of 100 µs for message reception

- Manual and periodic transmission of messages with a maximum resolution of 1 ms.

- Transmit CAN messages in response to remote frames (CAN 2.0 A/B only)

- Messages can be grouped into transfer lists, which can be saved and loaded as required, e.g. to simulate CAN nodes.

- Multiple flexible filters can be configured, e.g. assigned to send/receive windows or various trackers.

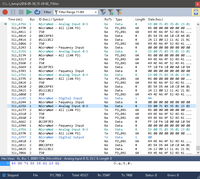

Recording and Playback

- Optional logging of CAN data traffic and errors that have occurred

- Tracking file playback with optional loop function

- Simultaneous operation of multiple tracers

- A representation of the recorded message with details such as timestamp, type, ID, length, and data byte.

- Data bytes in hexadecimal, decimal or ASCII format

- Filtering of messages for logging through message filters

- Record CAN data traffic directly to a file or RAM (in linear, dynamic, or cyclic buffer mode)

- Playback of recorded CAN messages directly from a file or buffer

- Save recorded data to a readable text file or CSV file for further processing in Excel or similar files.

- Enhanced handling of large trace files compared to PCAN-Explorer version 5

- The data recorded in the buffer is then checked against different symbol files.

Symbol indicates

- Clearly readable representation of CAN messages based on the PEAK-System symbol format:

- Easily assign CAN messages by assigning alphanumeric names

- Precisely categorize data by bit into variables for assigning names, data types, and so on.

- Easily create symbol files with the included Windows® software PCAN-Symbol Editor or the integrated text editor.

- User-friendly real-time monitoring of multiple signals through the viewing window

- Graphical display of up to 4 signals using a simple line writer (Line Writer Plug-in)

Automation with Macros and VBScript

- Use macros or VBScript to automate small tasks or complex processes, for example:

- Test procedures for CAN system implementation or development

- If the temperature is exceeded, please send an e-mail

- Activate the operation when a specific message is received

- Open the Excel worksheet when the event occurs and save the data in each cell.

- Calculation of variables based on data from incoming CAN messages

- Creating Macros and Scripts with the Integrated Text Editor

- Assigning Function Keys to Macros

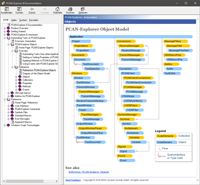

- Use VBScript to access almost all program elements through the PCAN-Explorer object model.

- Even without the PCAN-Explorer interface, VBScript macros can be run in the background.

Professional technical support from HONGKEI to help you succeed in your project.

HongKe's PEAK CAN / CAN FD analysis software series provides developers and engineers with efficient and intuitive tools for monitoring and diagnosing vehicle bus data. Whether it is real-time monitoring, message parsing, or advanced protocol analysis, PEAK supports CAN, CAN FD, and multi-channel applications, helping users to quickly locate problems and optimize communication performance during the R&D, testing, and maintenance phases. HongKe provides professional technology and complete support to help enterprises build stable and reliable in-vehicle communication systems.