- Home

- Technical Products

Enterprise Cloud IT Solutions

Test Measurement

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Latest Articles

- About Us

EN

EN

Multi-functional Miniature Shock Vibration Recorder

Are you looking for a compact data logger with large memory to handle various measurement tasks such as measuring and recording shocks, vibrations, temperature, humidity, pressure or light? Contact us to find the right data logger!

Related Products

HK-MSR165

1 built-in 3-axis accelerometer ±15 g or ±200 g

- 1600Hz

- Stores 2 million or 1 billion (SD card) measurements

- Optional built-in or external temperature, humidity, pressure and light sensors

- Analog Input

- Battery life 5 years

- MSR ShockViewer Impact Analysis Software

HK-MSR175

Two built-in 3-axis accelerometers ±15 g and ±200 g

- 6400Hz

- Stores 2 million measurements

- 1 built-in temperature sensor

- Built-in humidity, air pressure and light sensors

- Li-Po battery 230 mAh or Li-SOCI 2 battery

- MSR ShockViewer Impact Analysis Software

HK-MSR175 Plus

Two built-in 3-axis accelerometers ±15 g and ±200 g

- 6400Hz

- Stores 2 million measurements

- Built-in temperature, humidity, air pressure and light sensors

- GPS/GNSS receivers

- Li-Po battery 2400 mAh or Li-SOCI 2 battery

- MSR ShockViewer Impact Analysis Software

Economy

Economic Shock Recorder

ASPION Data Logger is your reliable partner for monitoring and securing valuable commodities in the global supply chain.

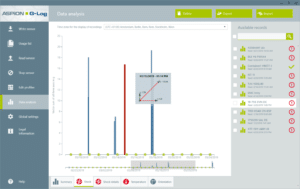

Multiple award-winning data loggers for transportation monitoring of shock and weather ensure transparency and security in your supply chain. Intelligent algorithms visualize shocks and impacts in meaningful detail and show the associated changes in temperature and humidity - easy to understand and flexible. Our "Made in Germany" energy-optimized sensor solutions enable the simple, safe and intelligent networking of processes and processes for the efficient organization of the entire logistics chain. Companies thus save valuable time and reduce costs. With other individually adapted electronic developments, we can create lasting benefits for your industrial applications and your customers.

Model Comparison

HJ-L-Track with real-time tracking function

The HJ-L-Track multi-sensor data logger with 360° real-time tracking lets you know the current location and condition of your shipments anytime, anywhere. With a powerful cloud-based platform, real-time data can be used to proactively intervene and control your supply chain.

- Detailed recording of shock and temperature/humidity

- Recognized proof of damage in case of shipment loss

- Wireless data transfer via NFC and Bluetooth

- License-free PC software and smartphone apps

- High price/performance ratio and award-winning performance

HJ-G-Log Series Impact Recorder

The rugged and cost-effective HJ-G-Log and HJ-G-Log 2 shock recorders are capable of recording shock and temperature and humidity data during transportation of sensitive goods. The waterproof version, G-Log 2 waterproof, is more suitable for unpackaged goods.

- Positioning in 140 countries via cellular network and GPS

- Real-time tracking via global mobile data transfer

- Shock, temperature and humidity, light, positioning, tilt and other conditions monitoring.

- Versatile cloud platform with real-time data and alarms

- End-to-end "Made in Germany and Custody" solutions

The data logger is intuitive to use and requires no training to operate. Ergonomic PC software and smartphone apps enable convenient wireless operation and comprehensive evaluation. Export function clearly prepares the data to be transferred. Extensive controls such as start and end dates, PIN assignment and time zone evaluation give you flexibility.

By the way: there are no follow-up costs after the purchase of the sensors, the PC software and applications are always free of charge for the user!

Everything is "Made in Germany".

The sensor's ABS plastic housing is compact, sturdy and discreet. Optimally matched components and intelligent power management allow for a battery life of up to 1.5 years, a long shelf life and resource-saving multiple use. But the sensors are also suitable for single use - especially because of their low price.

Shock sensors are suitable for sea and air transportation and can be used globally in intermodal transportation. They are easy to configure and install, so even untrained personnel can easily put them into operation. Data transfer is equally simple: all sensors communicate wirelessly via NFC, G-Log 2 and BLE.

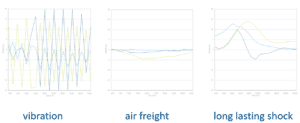

By recording shock and vibration or harmful temperature and humidity values as well as date and time, the cause of damage can be specifically determined. The data logger records up to 950 events. As shown in the example, a detailed shock process of milliseconds per shaft is particularly important. This can be used to identify any damaging transportation events. Packaging optimization can also be understood in this way.

Intelligent transportation monitoring in 2 minutes

Hongke Case

[HongKeys Solution] TSMC Adopts MSR175Plus Shock Vibration Recorder - A Professional Solution for Guaranteeing the Quality of Photomasks and Wafers in Transportation

Read more HongKeTechnology October 22, 2025

Professional technical support from HONGKEI to help you succeed in your project.

As a supplier specializing in industrial transportation solutions and an official MSR and ASPION authorized distributor, contact us for a free consultation and trial. HONGKEI is also committed to providing you with a range of paid technical services related to these products, which are designed to help you succeed in your projects in the most cost-effective way. Please contact us if you need technical services related to this product!