- Home

- Technical Products

Enterprise Cloud IT Solutions

Test Measurement

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Latest Articles

- About Us

EN

EN

Vehicle Network Communication Test Board

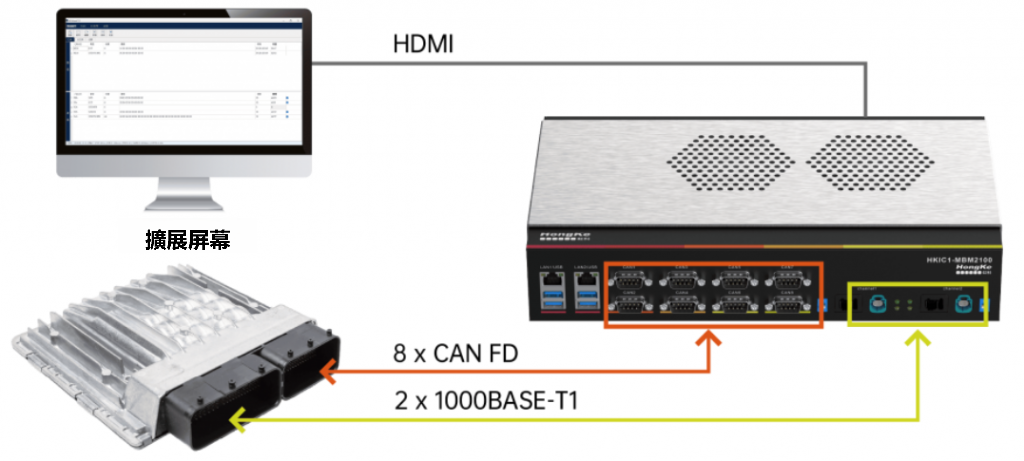

Workstations supporting 8x CAN/CAN FD & 2x 1000BASE-T1 protocols

The HKIC1-MBM2100 is a high performance industrial PC motherboard designed for vehicle network communication. It is used to monitor, emulate and simulate CAN (FD) and T1 network messages with powerful data processing and communication capabilities.

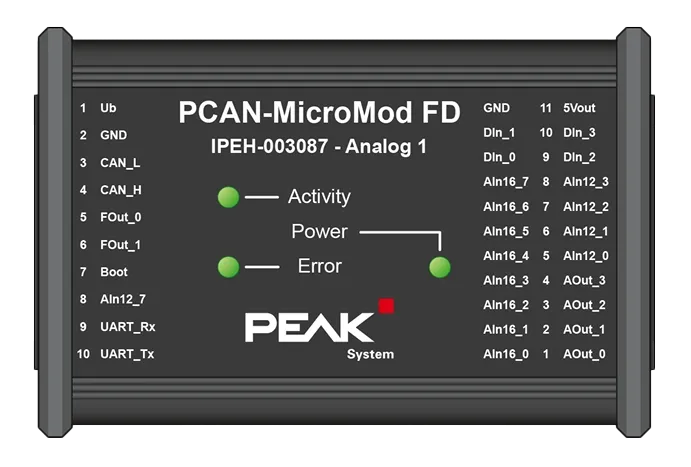

The motherboard integrates 8 CAN/CANFD interfaces and 2 1000BASE-T1 interfaces, and supports PCAN underlay driver, which can satisfy the test and data transmission needs in the complex vehicle network environment, and is widely used in automotive research and development, intelligent transportation, and vehicle inspection.

- Computing and processing with Intel i7 processor + 32G RAM (upgradeable)

- Compliant with CAN Specification 2.0 A/B and FD, CAN bit rate from 25 kbit/s to max. 1 Mbit/s; CAN FD data area (max. 64 byte) baud rate from 25 kbit/s to max. 12 Mbit/s

- 1000BASE-T1 interface status can be directly detected by external LEDs for easy diagnostics

- Hardware is compatible with Chinese version of HK-View and PEAK-CAN software (e.g. PCAN-View, PCAN-Explorer6, etc.); free API interface (supports C++, C#, Python, .)

- Flexible power supply via standard desktop or laboratory power supply

Industry Pain Points

Solving the three core pain points of automotive testing

Unstable data transmission?

Traditional test equipment often suffers from data loss and delay fluctuations in multi-protocol scenarios.

Complicated system integration?

Multiple equipment combinations lead to complicated wiring harnesses.

Large space occupation and synchronization difficulties

High maintenance costs?

Software Mandatory Upgrade Subscription

Average annual maintenance cost over $100,000

Product Advantage

Four core strengths to reshape the value of testing

All-in-one test platform

Multi-Protocol Support8 CAN/CAN FD (up to 12 Mbps) + 2 Gigabit Car Ethernet (1000BASE-T1) integrated, covering mainstream car network protocols

Industrial HardwareIntel 12th Generation i7 processor (optional), 32GB RAM (upgradeable), 1TB storage for high-load data processing needs

Dual System CompatibilityNative support for Windows/Linux systems, free API interface (supports C++, C#, Python, .NET, Java, etc.), seamless integration with existing workflows

Support Chinese versionHardware and Chinese version of HK-CoreTest, compatible with mainstream analysis software such as PCAN-View and PCAN-Explorer 6.

Intelligent Configuration and Diagnostics

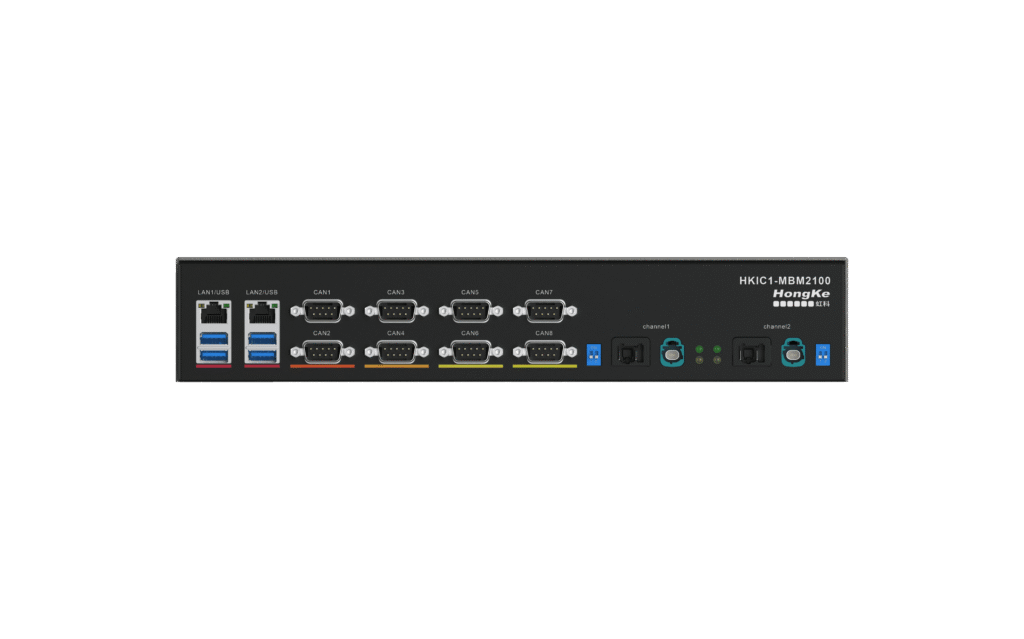

- Flexible Terminal ResistorsBuilt-in toggle switches to independently control the terminal resistance (120Ω) of each CAN channel to accommodate various network topologies.

- Master-Slave Mode Switching: One-touch configuration of 1000BASE-T1 master/slave mode via DIP switch for easy matching to the device under test (DUT)

- Bi-Color LED Status Light: Real-time monitoring of link status (green light: master/slave mode; yellow light: data transfer/normal connection)

Professional Interface Design

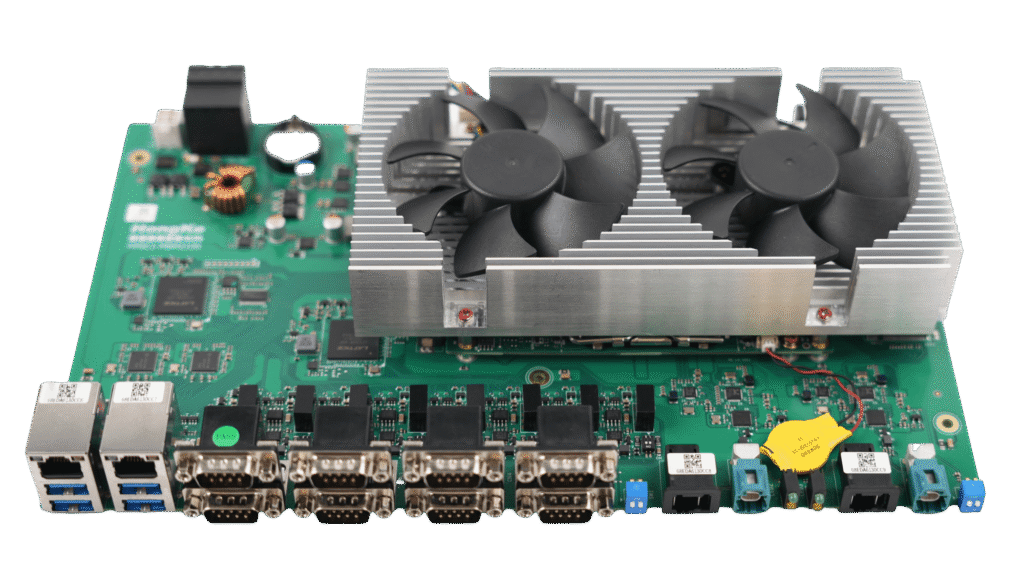

- CAN (FD) interfaceCAN 2.0A/B and FD compliant, supports 25 kbps-1 Mbps (arbitration zone) and 25 kbps-12 Mbps (data zone); TJA1044GT transceiver with FPGA controller to ensure signal stability

- Car Ethernet InterfaceDual 1000BASE-T1 with H-MTD/MATEnet connector support with shielded grounding (10Ω + 10nF)

Industrial Grade Reliability

- Wide temperature operationOperating temperature range of 0 °C to 60 °C for harsh on-board environments

- Security12V DC power supply (recommended starting current >5A), protection up to IP 20

- Compact Size: Motherboard size 300mm × 180mm, with optional chassis (320mm × 190mm × 580mm)

Functionality

In complex in-vehicle network environments, a single CAN protocol can no longer fulfill the usage requirements, and there is often a need to introduce technical requirements such as Ethernet. Faced with how toThe Challenge of Reducing Space and Simplifying Harness Layout(math.) genusHKIC1-MBM21000 Lightweight Vehicle-mounted Network Communication Test Motherboard (HKIC1-MBM21000)Provides solutions. This motherboard adopts an integrated platform design to verify the accuracy of data transmission, simulate fault conditions to test the response and processing capability of the ECU, support data performance testing under high load, and record the data and events during the testing process for subsequent analysis and optimization.

-

Data Collection and Recording

Through the in-vehicle Ethernet interface, data from sensors such as radar and cameras are collected in a high-speed and stable manner for real-time monitoring and recording.

-

CAN/CAN FD communication

It receives signals from the ECU of the vehicle, such as speed and steering angle, and also sends vehicle status information to the CAN bus, realizing synergistic operation with all vehicle systems.

-

Component Inspection and Diagnosis

Diagnosis and calibration based on UDS, XCP protocols

-

Port Expansion

USB 3.0 and Ethernet ports reserved for expanding LIN bus and IO ports

Product Information

Vehicle Network Communication Test Board (HKIC1-MBM2100)

bare metal

bare metal

bare metal

Shell

Shell

Shell

Ordering Information.

- Model:HKIC1-MBM2100

- Packing List: Mainframe, Power Adapter, Programming Interface API for development, User's Manual in PDF format (please contact Hongke)

Optional accessories:

- HMTD, MATEnet In-vehicle Ethernet cable

- DB9 Distribution Board, CAN Twisted Pair Cable

- Cooler and Chassis Enclosure

HONGKE Vehicle Network Communication Test Board (HKIC1-MBM2100)

| Project | Specification |

|---|---|

| Processor System | Intel 12th Generation i7 (optional/upgradeable) |

| Memory | 32GB (optional/upgradeable) |

| Storage | 1TB (optional/upgradeable) |

| Power Supply | 12-13.5V DC |

| Dimension (Housing Dimension) | (L)300mm × (W)180mm |

| Operating Temperature | 0 °C ~ 60 °C |

| IP Protection Class | IP20 |

| Power | 70W |

HONGKE Vehicle Network Communication Test Board (HKIC1-MBM2100)

| External Interface (REAR I/O) | Communication Interface (COMMUNICATION I/O) |

|---|---|

| 1 x HDMI (for display) | 8 x CAN (FD) (D-Sub, 9-pin) |

| 2 x GbE (RJ45, network connection) | 2 x 1000Base-T1 (MATEnet & H-MTD) |

| 4 x USB3.0 (5Gbps) |

HONGKE Vehicle Network Communication Test Board (HKIC1-MBM2100)

| Components | Model / Implementation |

|---|---|

| CAN(FD) Transceiver | TJA1044GT |

| CAN(FD) Controller | FPGA Realization |

| Base-T1 Transceiver | RTL8211FI-CG |

HONGKE Vehicle Network Communication Test Board (HKIC1-MBM2100)

| Component Items | releases |

|---|---|

| Operating System Support (OS Support) | Windows 8 / 10 / 11 and Linux |

| HK-View | Version 1.0 |

Click to download →HONGKE Vehicle Network Communication Test Board - User's Manual - V1.2

Software Introduction

HK-CoreTest Chinese Version Software

HK-CoreTest is a comprehensive tool for automotive electronic simulation and testing, which can be used to connect, configure and control all the ICP DAS hardware (including in-vehicle network communication test boards, PCAN-USB/PCIe series, in-vehicle Ethernet tools, etc.) to realize monitoring, simulation and diagnostic functions of the automotive bus.

Base Function:

- Supports CAN/CAN FD and in-vehicle Ethernet data processing.

- Supports DBC, ARXML database.

- Realize the function of sending/monitoring/playing back the reports.

- Supports bus statistics and data logging

Advanced Features:

- Supports diagnostic configuration and diagnostic services, and enables automated diagnostic functions with FBL brushing based on the UDS protocol.

Compatible with PCAN series software (e.g. PCAN-View, PCAN-Explorer 6, etc.) and their API interfaces.

Windows System Environment

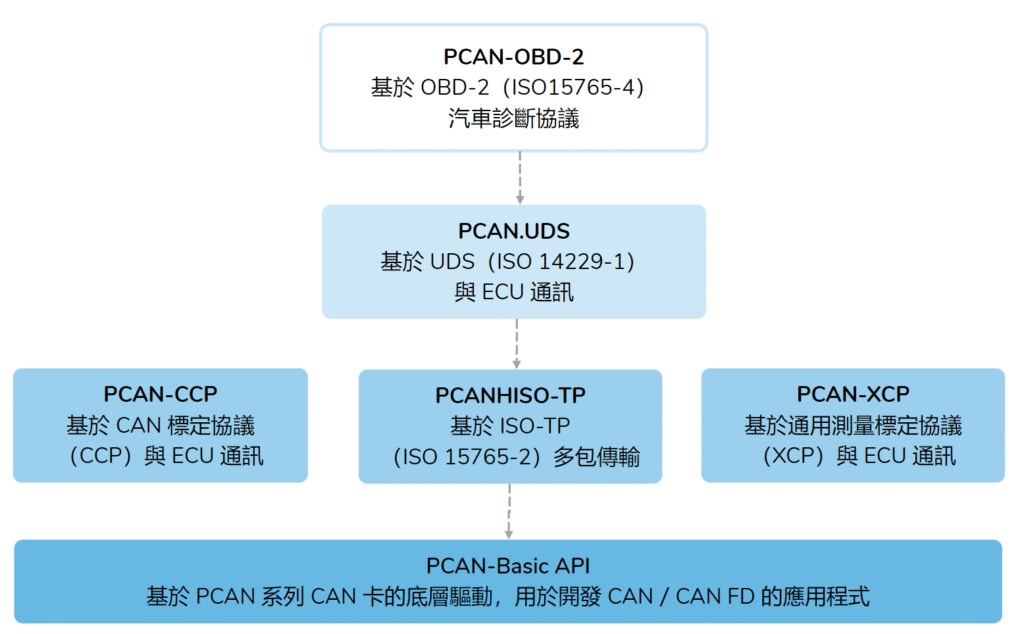

- Supports PCAN-Basic for Windows: Includes a physical device driver and interface DLL (Dynamic Link Library) that provides an API interface to support C++, C#, C++/CLR, Delphi, VB.NET, Java, and Python 3.x languages with corresponding header files and sample programs.

- Supports API implementations of ISO-TP standard (ISO 15765-2), UDS standard (ISO 14229-1), etc. Supports languages such as C++, C#, C++/CLR, Delphi, VB.NET, and Python 3.x, and provides corresponding headers and sample programs.

Linux System Environment

- Supports PCAN-Basic for Linux (32/64-bit). Provides API interfaces to C++, C#, C++/CLR, Delphi, VB.NET, Java, and Python 3.x with corresponding headers and sample programs.

- Supports SocketCAN.

Vehicle Network Communication Test Motherboard Accessory Kit

-

HKIC1 MBM2100 基礎套裝

-

HKIC1 MBM2100 標準套裝

-

HKIC1 MBM2100 定制套裝

Application Scenarios

Domain Controller Deep Validation

Simulates a multi-ECU communication environment to test protocol compatibility and real-time performance.

Fault Injection × Fault Tolerance

Verify controller robustness by simulating bus errors, network delays and high load shocks.

Data recording

Capture the complete testing process to support backtracking and consistency analysis.

Hongke Case

HONGKE Solution] Low Cost CAN FD Enables Robot "Fingertip Intelligence" - Precision Collaboration Control Analysis

Read more HongKeTechnology December 17, 2025

Professional technical support from HONGKEI to help you succeed in your project.

As a provider specializing in machine vision and optoelectronic inspection solutions, Avision is also committed to providing you with a range of paid technical services related to this product, aiming to help you succeed in your project in the most cost-effective way. Please contact us if you need technical services related to this product!