【虹科方案】AI+AR 重塑 PCB 質控流程|虹科 AR 智慧質檢解決方案

虹科結合 AR 智慧眼鏡與 AI 辨識技術,打造標準化 PCB 質檢工作流程,整合 MES、ERP、AOI 系統,降低漏檢率、提升良率,加速電子製造數位化升級。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Case Overview

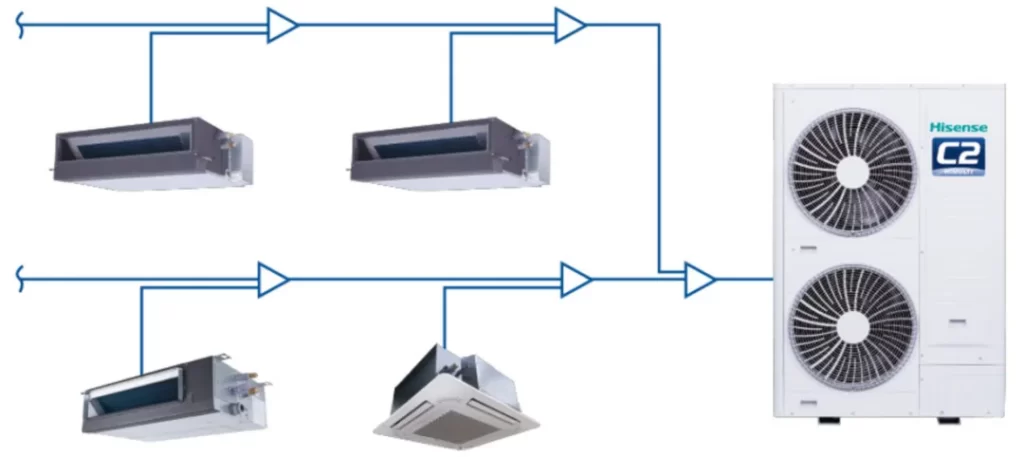

Customer: Hisense Hitachi

Application: MSR165 & MSR175 Shock Vibration Recorder

Application Scenario: Environmental monitoring of long-distance transportation of central air-conditioning equipment.

Hisense Hitachi Air Conditioning Systems (Qingdao) Co., Ltd. is a leading enterprise integrating central air conditioning system design, manufacturing and whole life cycle service. With years of deep plowing in the field of inverter multiple units, the company continues to lead the industry in technological upgrading by virtue of its strong R&D strength and high standard manufacturing capability.

In the central air conditioning industry, vibration, shock, and changes in temperature and humidity to which equipment is subjected during transportation and storage often pose potential risks to the quality of the final product.

Central air conditioning products are large and complex, and are susceptible to impact, vibration and environmental changes during logistics and storage. If these risks are not immediately quantified and identified, they can lead to breakage of the copper tubes of the outside unit and damage to sheet metal parts, which in turn can lead to returns and after-sales problems.

According to Hisense Hitachi, the cost of returning and replacing an external machine due to transportation problems can be as high as tens of thousands of dollars, and if it is concentrated, it will bring high economic losses and brand reputation risks.

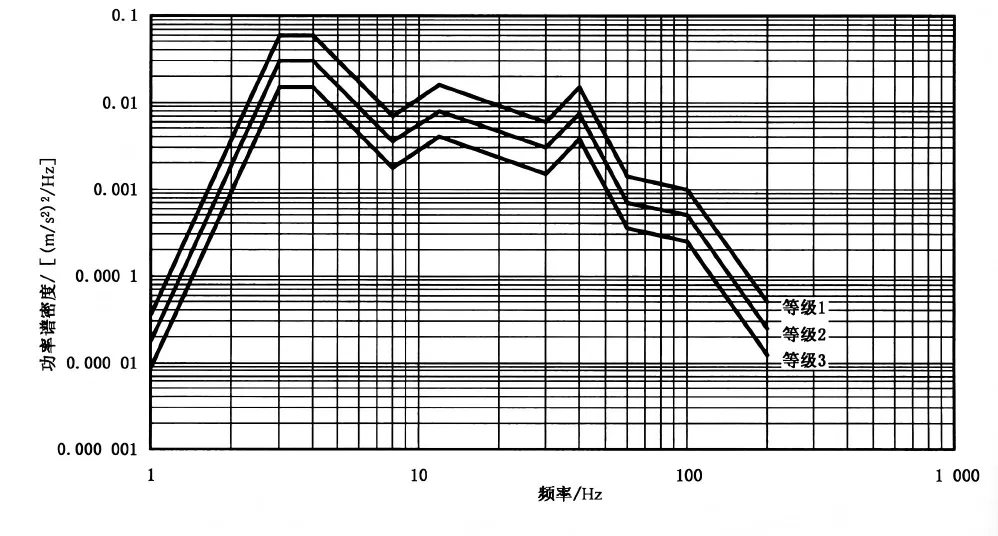

In order to minimize the potential hazards of transportation, the technical team designs and equips marine transportation packages according to the national standard GB/T4857.23, "Random vibration test method for package transportation", and evaluates the structural strength and protection ability of the packages under random vibration. Therefore, how to accurately monitor the vibration strength during the actual transportation process and compare with the standard has become a key demand.

To scientifically reproduce the transportation stress scenarios, Hisense Hitachi chose to use the MSR165 Miniature Shock and Vibration RecorderCompact, waterproof, durable, low power consumption. Compact, waterproof, durable, low power consumption, high sampling frequency, and a battery life of up to 6 months, it is very suitable for long-distance transportation testing.

Engineers installed the MSR165 on the bottom of the sheet metal of the external machine to collect the data of acceleration, temperature and humidity during the whole transportation process.

By setting the 1.5g trigger threshold and 400Hz sampling frequency, vibration and shock signals can be captured completely. The PSD (Power Spectral Density) curve is then generated by MSR software and compared with the national standard:

Reproduce transportation and structural damage (e.g., cracked copper tubing)

Verification of New Designs

Optimized packaging and mechanisms

Modeling of corporate-owned transportation environments

In addition, MSR equipment can synchronize temperature and humidity measurements, which helps to set standards for warehouse environments.

Through the MSR165's high-precision monitoring and visualization analysis, Hisense Hitachi identifies potential design risks in advance of the new product stage and makes targeted improvements to packaging and structure. This significantly improves the transportation reliability of products and saves approximately Adverse market loss of $2 millionThe

Accurate data also improves development efficiency, strengthens quality control processes, and increases trust in the brand among end markets and partners.

Hisense Hitachi first learned about MSR from a vibration/impact case, and after comparing similar products in the market, found that some of the domestic equipment had limitations such as large size, small storage, and lack of accuracy, and were not able to support long term transportation monitoring.

And the Swiss-made MSR165 With high precision, small size, high reliability and strong endurance, it was finally adopted by Hisense Hitachi team.

MSR165 only 39×23×72 mm, 64gCoca-Cola 1600 Hz High-speed acceleration sampling with 13-bit resolution and built-in high-precision 3-axis accelerometer for simultaneous recording of temperature, humidity, pressure, light and other environmental parameters.

The built-in recording capacity is over 2 million data items and supports tens of thousands of impact measurements, making it suitable for long term high precision monitoring.

General shock recorders can only record short data at the moment of over-threshold, which is difficult to be converted into frequency domain data. However, MSR165 can continuously record the complete time domain data at high frequency and completely restore the vibration events in transportation.

MSR165 generates vibration phase, amplitude, power, and PSD spectra through Fourier transformation, and can be directly compared with the requirements of the national standard, so that enterprises can make scientific decisions based on data rather than experience.

In the face of huge amount of data, MSR suite provides quick analysis tools, such as the MSR175's "Ultra Threshold Event Mode" which avoids redundancy and makes the analysis more efficient.

虹科結合 AR 智慧眼鏡與 AI 辨識技術,打造標準化 PCB 質檢工作流程,整合 MES、ERP、AOI 系統,降低漏檢率、提升良率,加速電子製造數位化升級。

深入解析虹科 GNSS 模擬器如何支援無人機整機測試,涵蓋多星座 GNSS 仿真、RTK 公分級定位、抗干擾測試與多感測器融合驗證,助力高效、安全的 UAV 研發。

增材製造(PBF-LB/M)中的高精度過程監控與誤差檢測,虹科 iDS USB3 工業相機助力粉末層、再熔化層與動態飛濺監控,提升部件品質與研發效率,適用航空航天、醫療、汽車等行業。