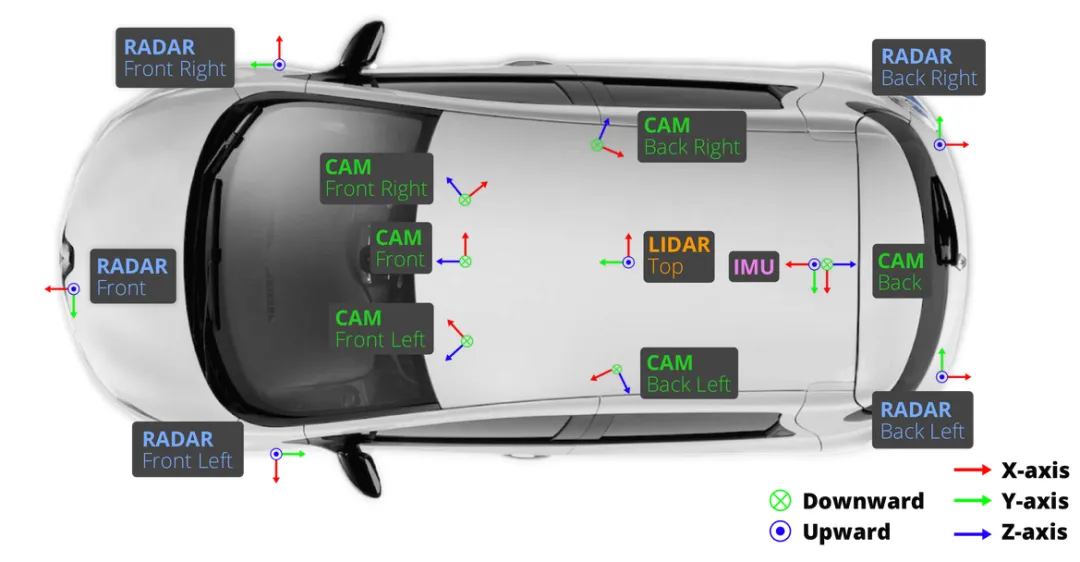

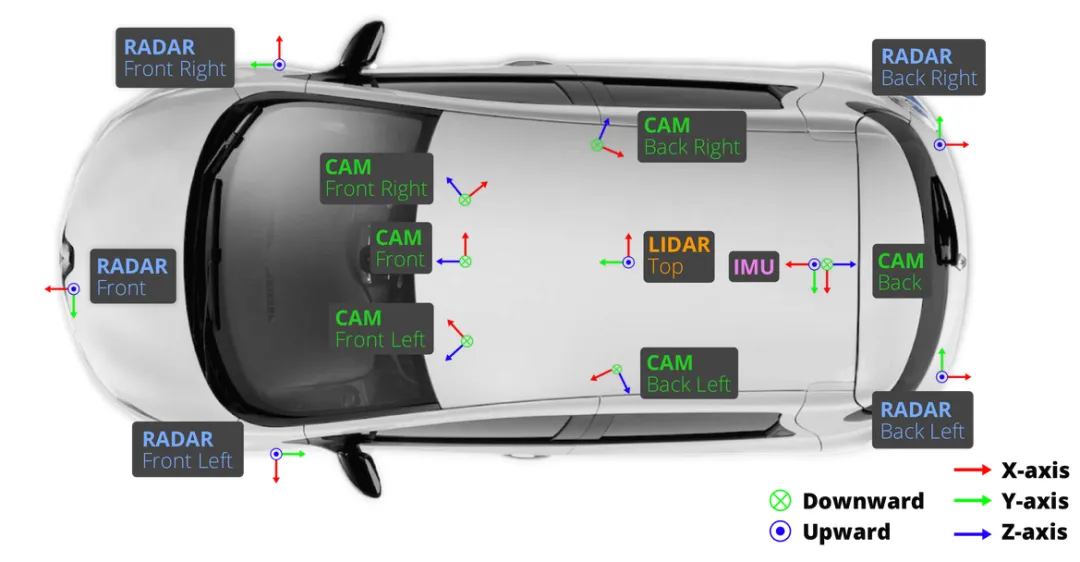

【虹科方案】 SimData 高保真虛擬數據集 – 基於 aiSim 的自動駕駛多傳感器感知數據方案

SimData 為基於 aiSim 仿真平台生成的高保真虛擬感知數據集,支援 Camera、LiDAR、Radar、IMU 多傳感器同步數據,結構完全對齊 nuScenes,可直接使用 nuscenes-devkit 進行解析與模型訓練。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Have you encountered any of the following typical scenarios when working with Southeast Asian factory teams across borders?

Risk-based Pain Points: A Direct Threat to Enterprise Security and Compliance

1. High information security risk

Many factories still rely on third-party communication tools such as WeChat, Line, WhatsApp, etc. for remote collaboration, which involves the following risks:

Data transmission may be intercepted or leaked.

Exposure of core secrets such as production process, equipment parameters, supply chain flow, etc.

Cross-border data transfers may trigger local compliance risks (e.g. PDPA, GDPR)

These are the major pitfalls faced by overseas enterprises.

Efficiency pain points: the production rhythm is forced to slow down

1. Inefficient productivity processes

Abnormalities occur frequently in overseas factories due to unstable equipment and unskilled operation, and the time-consuming and primitive process of abnormality checking directly slows down the overall production progress.

2. Slow communication response

Cross-country teams are often encountered:

Email response is slow

Language barrier in various places (especially Thailand, Vietnam, India)

Difficulty in accurately describing field problems by front-line operators

Remote Voice Guidance Misoperation Due to Insufficient Clarity of Expression

The efficiency of cross-boundary co-ordination is extremely low, and there are even cases in which "the repairs are getting worse and worse instead of being clear".

3. Weak knowledge transfer

Mature engineers need to teach new hires one-on-one, and there is a lack of it:

Standardized Operating Procedures

Reusable Technical Documents

Traceable operating records

This results in the same problem occurring over and over again, wasting time and cost.

Cost pain points: frequent travel + high training costs

1. Extremely high cost of cross-border travel for technical experts

Take the data of a manufacturing customer of Hongke as an example:

Monthly average 5 Engineer trips

Cost per person per visit ≈ $3,000

included among these 2/3 Travel For support of off-site factory commissioning

Not only is it costly, but it also affects engineers' schedules and health, and it's not sustainable.

2. Difficulties and Hidden Costs of Local Staff Training

Overseas new staff in general:

Insufficient operational experience

Limited equipment understanding

Long training cycle

Additional wastage and depletion due to unfamiliar operations

It increases operating costs in the long run and reduces capacity stability.

When an overseas factory encounters a technical problem during production, maintenance or equipment commissioning, HONGKE AR Remote Assistance provides immediate, accurate and efficient cross-border technical support.

The core value is:It allows engineers in the China headquarters to see every detail as clearly as if they were standing on the site of an overseas factory in Thailand, Vietnam, or India, and to instruct operations immediately.

This is the core value of HONGKE AR remote assistance: it truly breaks down the space and time barriers across borders, and allows remote technical guidance to be transformed from "shouting over the air" to "face-to-face" efficient collaboration.

AR Remote Assistance is not just an ordinary video call tool, but an industrial-grade collaboration solution that deeply integrates AR, AI and digitalization technologies, and is specially designed for the manufacturing industry and overseas factories. Its core competence has been recognized by the global authority in the XR field:

Hongke's AR one-stop solution won the "Auggie Awards Best Enterprise Solution", the world's top XR honor, and its Vuzix AR smart glasses have more than 400 patents and have won the CES Innovation Award for 18 consecutive years.

1. Real-time 4K HD Audio and Video: Communicating Across Borders in Real Time

Supporting 4K high-definition images and two-way audio real-time interactions, it ensures clear images and stable sound even during cross-country collaborations, making remote experts feel as if they were on-site.

2. AR Overlay Note: Efficiency Improvement 50%+

Experts can overlay instructions such as arrows, circles, text, 3D models, etc. directly in the operator's field of view, increasing collaboration efficiency by at least 50% compared to verbal descriptions.

3. One-Click Recording: Precipitate Experience into Reusable Assets

The entire instruction process can be completely recorded for subsequent review, training and quality traceability, allowing senior engineers to standardize and systematically preserve their experience.

4. AI Cross-Language Support: Removing Barriers to Cross-Border Collaboration

Support 28 languages (including Cantonese), fully adaptable to Thailand, India and other overseas factory scenes, effectively avoiding the misunderstanding caused by the language barrier.

5. End-to-end information security: avoid information leakage and compliance risk.

Uses AES-256 end-to-end encryption

Support for Overseas Localization Deployment

Passed GDPR, Thailand PDPA, India DPDP

Block the security risks caused by third-party chatting tools at the source.

6. Industrial grade protection: not afraid of high dust and high humidity.

With IP67 protection rating, 2m drop test and various IEC/ISO certificates, the AR goggles can be stably adapted to harsh industrial environments.

7. Super easy to use: 30 minutes for zero-based employees to master the program

Provides voice, button, touch, PC control, etc., so that new employees can use it quickly.

8. Open Platform: Supporting Secondary Development for Enterprises

Equipped with Qualcomm XR1, Android 13, supports self-developed APP, SDK development and seamless integration with enterprise systems.

9. 10-hour enterprise-class battery life: full shifts without downtime

It can be used continuously for 10 hours on a single charge to meet the all-day needs of factories.

10. Flexible Deployment: Remote Push Online / Offline Installation

Adapts to different network environments and provides 160+ industrial applications.

11. AI-assisted diagnosis (optional)

It can automatically recognize the status of equipment and part models to enhance the efficiency and accuracy of troubleshooting.

Selection AR Remote AssistanceYou will get:

| Dimension | Traditional | AR Smart Glasses |

|---|---|---|

| Cost structure | High travel costs (over a million dollars per year) | Zero travel cost, save more than 60% of operation and maintenance expenses annually. |

| Response Time | 24-48 hours (delayed across time zones) | Real-time response (resolution within ≤ 4 hours) |

| operating efficiency | Relying on manual experience, misoperation rate 15% | Standardized AR guidance, misoperation rate ≤3% |

| Passing on Knowledge | Experience is easily lost through word of mouth | Standardized precipitation to form a reusable knowledge base |

| Data Security | Easily leaked e-mail/telephone transmissions | Localized deployment, AES-256 encryption |

There is the formation of fruit:

Revenue = Estimated savings (travel budget + lost hours due to equipment anomalies) - Input costs (depreciated over 5 years)

Tested by a manufacturing customer of Hongke:The revenue of a single station is over RMB 200,000 yuan.

There are no fruits:

Reducing production abnormal working hours

Reducing complaints from frontline staff

Improve on-time delivery

Enhance customer satisfaction

Q1. Can Hongke AR Remote Assistance really solve the real problems of overseas factories in Thailand and India?

A1. Absolutely. For overseas factories "Slow response, high cost, difficult communication, lack of talents". HONGKE's core pain point is that we are able to provide the best service to our customers through "First View Real-time Video + AR Overlay Guidelines."In addition, the Chinese experts were able to visit the site "from afar".

Troubleshooting from Days reduced to hoursThe solution has been used by many customers in their Southeast Asian factories for a long time and is a proven, practical and truly effective tool. The solution has been running steadily for a long time in the Southeast Asian factories of several customers, and is a mature, practical and truly effective industrial-grade tool.

Q2. The network of overseas factories is poor (bandwidth is limited and unstable), can I still use AR Remote Assistance smoothly?

A2. Yes, the product has been optimized for "weak network environments".

Bandwidth OptimizationThe system utilizes advanced codecs and dynamic bit rate adjustments to maintain picture clarity at low bandwidths; audio and markup commands are prioritized for transmission.

Support offline operationStandard Operating Procedures (SOPs), operation manuals, etc. can be called up offline without relying on the Internet.

Multi-Network Adaptation: Fully compatible with 4G / 5G / Wi-Fi, network testing and optimization recommendations are available prior to deployment.

Q3. Are the AR glasses and system easy to use for field operators who are not familiar with high technology?

A3. Easy to follow!

The Vuzix AR goggles are designed with the core idea of "not adding burden to the frontline staff".

Hardware:

Lightweight and comfortable to wear all day without stress

Supports voice, touch, and key interactions.

Software:

Simple interface and clear steps

Core functions at a glance.Can be operated independently with only 30 minutes of training

Services:

Provide full process deployment, operational training and ongoing support

Q4. How can I protect my data security and privacy when transferring video and operational data across borders?

A4. Data security is the "lifeblood" of Hongke. End-to-End Security Protection Framework::

Bank-level AES-256 encryptionEnsure that all audio, video, annotation and AI information is secure in transmission and storage.

Flexible deployment model: Public Cloud / Private Cloud / Localized Deployment (can be directly deployed in overseas factories)

Session Privilege Protection: Authorized login is required, and passwords and access rights can be set to prevent unauthorized use.

Q5. In addition to remote assistance, what other values can HTC AR industrial solutions bring to the digital transformation of enterprises?

A5. AR Remote Assistance is more than just a "tool to solve the problem at hand", it's Entrance to Enterprise Digitization::

Numerical Workflow: Conversion of SOPs, maintenance manuals into AR visualization guidelines

precipitation of knowledgeAutomate recording processes to build a reusable enterprise knowledge base.

AI Assist Capability (optional): Auto Meter Reading, Parts Identification, Fault Prediction

Decision DataGenerate data such as fault type, processing time, one-time resolution rate, etc. to help management formulate strategies.

Q6. How to evaluate the return on investment (ROI) of AR Remote Assistance?

A6. transferable from Quantification of the four core perspectives Evaluate ROI:

Cost Savings: Reduce international travel, downtime losses, and expert labor costs

Efficiency gains::

Reduced Mean Time To Repair (MTTR)

Shortened training cycle for new employees

Significant increase in one-off settlement rate

Quality and Safety: Decrease in the rate of misuse and reduction in the rate of accidents

Value of Knowledge: Accumulate digitalized SOPs, AR tutorials, and expert libraries to form long-term reusable assets.

HONGKE Consultant Team can help companies set up KPIs before the project starts and provide clear ROI analysis report after the project is launched.

SimData 為基於 aiSim 仿真平台生成的高保真虛擬感知數據集,支援 Camera、LiDAR、Radar、IMU 多傳感器同步數據,結構完全對齊 nuScenes,可直接使用 nuscenes-devkit 進行解析與模型訓練。

虹科 AR 遠程醫療解決方案整合醫療級 AR 智慧眼鏡、AI 即時翻譯與遠程會診技術,支援跨語言醫療溝通、臨床教學與國際醫療合作,推動智慧醫療流程數位化升級。

虹科 PCAN 卡應用於隧道挖掘設備電控系統,支援 CAN / CANopen / J1939 通訊,協助工程設備實現穩定資料傳輸、精準控制與高可靠性運作,適用於鑿岩台車與隧道施工設備。