- Home

- Technical Products

Enterprise Cloud IT Solutions

Test Measurement

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Latest Articles

- About Us

EN

EN

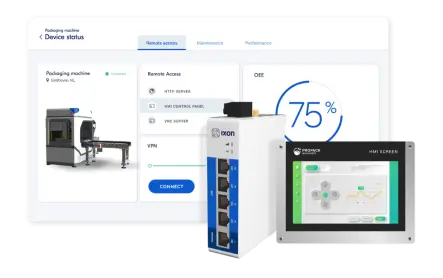

IIoT Remote Access System

Remotely connect to your on-site machine via a secure VPN. Supports VNC and HTTP WebAccess for direct access to your HMI and Web user interface from a cloud portal.

High-speed VPN

Stable and high-speed remote connection to your PLC, HMI, IPC, robot and IP camera via a browser. Your computer will automatically connect to the nearest VPN server in the IXON Cloud network.

Web-based

Remotely access control panels directly from mobile devices without installing a local VPN client to view in real time the human machine interface (HMI) in a PLC, robot, or educator, as well as diagnostic information, status, or setup data from a local Web server.

No user license required

IXON Cloud ensures that everyone has secure access to devices without compromising on risk. This centralized platform supports secure, license-free collaboration with colleagues and customers.

User Friendly

Our zero-code solutions are as friendly to technicians as they are to non-technicians, and the plug-and-play design of the IXON Edge Gate ensures that remote service configuration is quick and easy. Our focus on extreme ease of use ensures that your valuable time is not wasted.

Provides multiple remote access options

- Secure VPN connection: for remote access to PLC software

- Remote access to HMI screen via VNC: Controls machine operator panels

- Via HTTP: Get a web page view of the machine settings or access the surveillance camera.

- Using WebSocket: Monitoring Specific Data Traffic

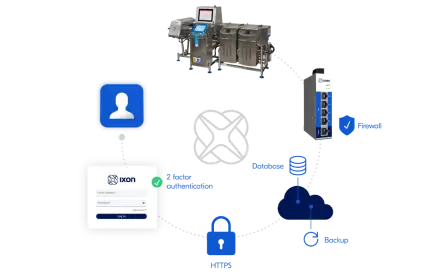

Reducing Cybersecurity Risks

To secure the plant's local network, IXON edge gateways have built-in firewalls and access to the IXON cloud platform via a VPN connection. An advanced role-based (RBAC) user management system and a mandatory double authentication (2FA) mechanism prevent unauthorized access to equipment or high-level settings, and IXON's ISO 27001-compliant Information Security Management System (IMS) protects against potential security breaches.

Fully compatible with all industry standards

Our industrial VPN routers are compatible with all major PLC brands (e.g. Siemens, Allen Bradley, Mitsubishi) and support a wide range of industrial communication protocols, including OPC-UA, ModBus, and Siemens S7 protocols.

Frequently Asked Questions

What is (Industrial) Remote Access?

Industrial remote access refers to the ability to remotely connect to and control industrial machinery, such as PLCs and HMIs, over the Internet, often over a secure VPN connection, allowing technicians to monitor, troubleshoot, and configure equipment anytime, anywhere.

What is a remote connection?

A remote connection is a link established over the Internet that allows a user to access and control a device or system from a different physical location. In industrial environments, this typically involves connecting to a machine or control system to remotely perform operations such as maintenance, updates, or diagnostics.

How does remote access to the machine work?

Remote access is achieved through devices such as the IXrouter, which establishes a secure connection between the industrial machine and the cloud platform. This connection is usually established through a VPN, which ensures data encryption and secure transmission. Once the connection is established, users can remotely access the machine control panel and view diagnostic information.

Here is how IXrouter and IXON Cloud work:

1. connection setting

Install a device such as IXrouter on the machine and access the Internet via Ethernet, Wi-Fi, or 4G.

2. Secure VPN tunnels

IXrouter establishes a secure VPN tunnel with IXON Cloud, ensuring that all data transmitted is encrypted and protected.

3. Access and control

Authorized users can access the machine remotely through the IXON Cloud using services such as VNC (remote desktop), HTTP (web interface) or WebSocket. This configuration allows users to monitor, troubleshoot and update equipment from any location.

What are the advantages of remote access for machine builders?

The benefits of remote access for machine builders include:

- Reduce downtime: Quickly resolve problems without waiting for on-site personnel to arrive

- Cost Saving: Reduces travel and labor costs and reduces the need for on-site support

- improve efficiency: Perform Updates and Maintenance More Efficiently

- Enhanced Support Services: Provide customers with more immediate and comprehensive technical support through remote access to the machine

- Highly scalableCentralized management of multiple devices and sites from a single platform

Remote Access in Industry

Remote access is widely used in the following scenarios:

- Remote troubleshooting and maintenance of machines

- Remote Programming and Configuration of PLCs

- Industrial equipment monitoring and data logging

- Provide support and training to field staff

Remote commissioning of new equipment and systems

What are the use cases for remote access?

- Remote Troubleshooting: Diagnose and repair problems without the need for an on-site visit.

- Preventive Maintenance: Predict and prevent potential malfunctions through equipment monitoring.

- Remote Monitoring: Continuous monitoring of machine performance and operating status.

- Configuration and Updates: Remotely update software or system settings on industrial equipment

- Support & Training: Provide immediate technical support and instructional training to field operators.

Is remote access secure?

IXON has implemented a number of security measures to ensure a high level of protection. These measures include:

- Establishing an encrypted connection using a VPN

- Built-in firewall in edge gateway for network isolation

- Adoption of Role-Based Access Control (RBAC)

- Complies with a number of international safety standards, such as:ISO 27001(Information Security Management);ISO 27017(Cloud Services Security);ISO 27701(Privacy Information Management)IEC 62443(Industrial Automation and Control Systems Qualification)

How to ensure the security of remote access?

The security of remote access is ensured by a multi-layered protection mechanism:

- Encrypted VPN Tunnels: All data transfers between the machine and the cloud are encrypted through a secure VPN tunnel, effectively preventing unauthorized access.

- Built-in firewall: IXON's edge gates have a built-in firewall that separates the machine network from the plant's internal network, increasing the overall level of protection.

- Role-Based Access Control (RBAC): Access to devices and data is managed through RBAC, ensuring that only authorized users can use specific features and access sensitive data.

- Two-factor identity test (2FA): Enabling 2FA adds an additional layer of authentication to user accounts, significantly reducing the risk of unauthorized access.

- Compliance with international security standardsIXON strictly complies with international information security standards such as ISO 27001, ISO 27017, ISO 27701 and IEC 62443, and conducts regular audits to ensure continuous compliance and high level of security.

Can Industrial Remote Access be integrated into existing systems?

Yes, Industrial Remote Access can be fully integrated into existing systems. ixon provides an open API for seamless integration with all types of IT and OT systems. This integration enables the following features:

- Data Exchange: Secure data transfer between machines and enterprise systems such as ERP, CRM and other business applications.

- Automation: Supports an automated configuration process that can be used to deploy new devices or push updates directly from existing systems for greater efficiency.

- Customized Solutions: Enhance the overall IIoT architecture by developing customized applications and services based on enterprise-specific needs.

- Scalability and Flexibility: An open and well-documented API ensures that solutions are forward-looking, responsive to changing business needs, and not limited to a single vendor.

Customer cases using IIoT remote access systems

Italian sawmill manufacturer Storti

To address network security risks, Storti uses the IXON system for compliant remote maintenance. The solution is internationally certified, with features such as audit trails and centralized management of equipment, which can meet the needs of customers of different sizes and simplify the installation process at the same time. In the future, Storti will further enhance the standard of customized services.

Heiploeg, the Dutch shrimp giant.

In order to unify the management of equipment from multiple vendors, Heiploeg requires all new purchases to include an IXON router, which enables remote maintenance through a secure VPN, not only reducing service costs by 90%, but also ensuring network security and operational autonomy.

Bakery Equipment Manufacturer Minipan

Minipan's IXON platform enables remote monitoring and control of bakery equipment, and after-sales service efficiencies, driving sales growth of 35% by 2023. its dashboard and secure access capabilities are key differentiators in a global market.

Professional technical support from HONGKEI to help you succeed in your project.

As a provider specializing in machine vision and optoelectronic inspection solutions, Avision is also committed to providing you with a range of paid technical services related to this product, aiming to help you succeed in your project in the most cost-effective way. Please contact us if you need technical services related to this product!