- Home

- Technical Products

Enterprise Cloud IT Solutions

Test Measurement

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Latest Articles

- About Us

EN

EN

- Pano SCADA Industry Program -

Food & Beverage Medicine

Pharmaceutical Production Management System | Food Factory Production Management System

Pano SCADA software platform can realize enterprise cockpit and section control management, batch management and data analysis and recipe management, and construct high-efficiency food production and processing management system and pharmaceutical production management system to help enterprises realize digital transformation.

Industry Programs Introduction

| Panorama SCADA

Facilitating the digital transformation of the food and pharmaceutical industry

In the process of digital transformation of the food industry, MacroMedia Panorama SCADA can help enterprises build food factory production management systems to improve production efficiency and reduce energy consumption: real-time monitoring and control of key indicators, so that enterprises can detect failures in time to avoid production interruptions; collection and recording of historical data, so that enterprises can understand the trend of changes in production data, optimize production processes; real-time monitoring of energy consumption It also helps enterprises to detect high energy-consuming equipment or processes. MacroMedia Panorama SCADA supports seamless switching between PC, tablet, and mobile APP interfaces, allowing enterprises to view and control key production data at any time, making it the intelligent engine of future food production and processing management systems.

| Food Hospital Industry Demand Analysis

Designed to meet the challenges of the food and pharmaceutical industry

Compliance

Equipment Management

Batch traceability and records

Recipe Management

- Industry Certifications

- Data Security

- Running Time

- Downtime

- Percentage of Failure

- Equipment KPIs

- Equipment Information

- Audit Trails and Electronic Signatures

- Batch data recording and traceability

- Ingredient Selection

- Ratio Adjustment

- Process Optimization

- Standardized formulas

Quality Control Chart

Enterprise Warehouse Management

Energy management analysis

Production Report

- Production Equipment Data

- Comparison of waste data

- Production Costs and Efficiency

- Data Management

- Data Interaction with WMS/WCS

- Electricity/Water/Gas Analysis

- Various types of charts

- Manual Input

- Customized Report Sample

- Drag Generation Key Data Analysis

- Shift/day/weekly report

| MacroMedia Pano SCADA Solution Architecture

- Panorama COM: Intelligent Communication Front End for Data Acquisition and Transmission

- Panorama E2: Mainly used for data acquisition and visualization, data processing, alarm management (voice, SMS, etc.), remote control, video surveillance and other SCADA functions.

- Panorama H2: a solution for historical data processing, enabling report generation and analysis, predictive maintenance, energy consumption analysis, etc.

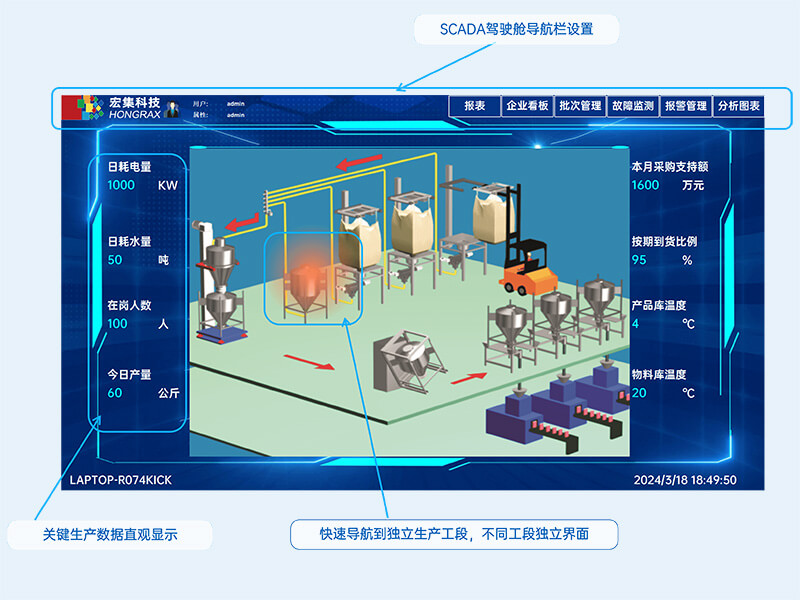

| Corporate Cockpit Management

- Interface with WMS/WCS system data

- Corporate Key Figures

- Setting up the SCADA navigation bar for different interfaces.

- Quick navigation to different sections

| Segment Control Management

Configuration of segment key information customization

- Equipment Running Status

- Current Batch Process Parameters

- Current Batch Work Order Information

| Batch Management

- Production batch configuration: batch number, product type, production quality/volume configuration

- Production batch selection: pending batch & in production batch

- Display of traceability information of batches in subsections

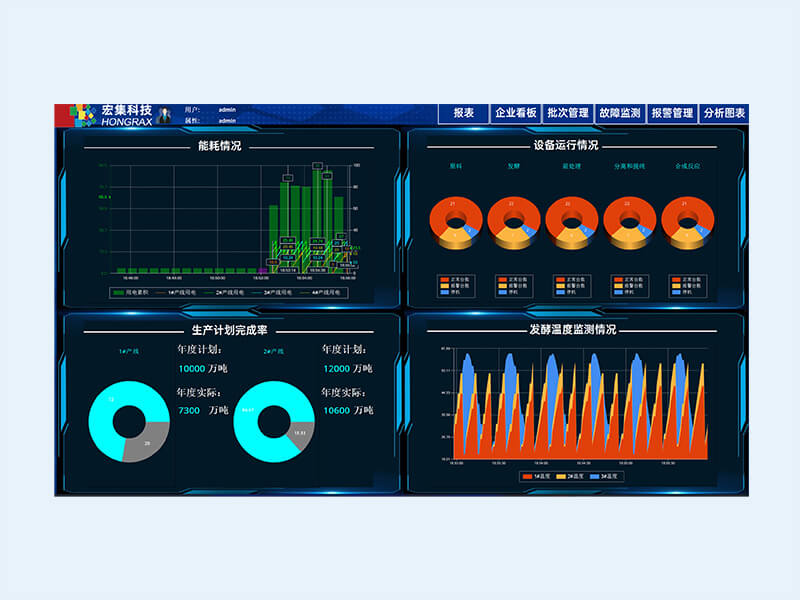

| Data Analysis

- Multiple available charts to visualize data

- Displaying different charts on the same screen

- Based on the results of the trend comparison analysis

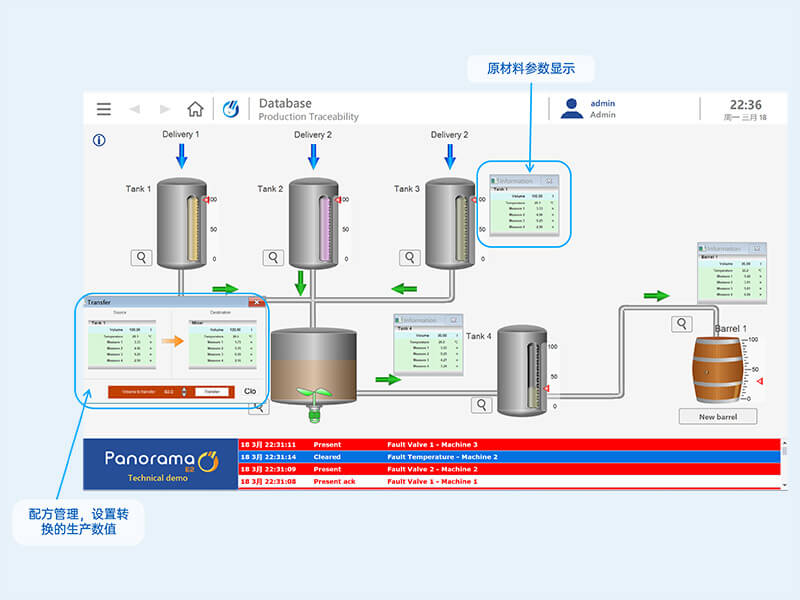

| Recipe Management

- Setting the recipe parameters

- Conversion Process Parameter Setting

- Display of industrial parameters for raw materials and finished products

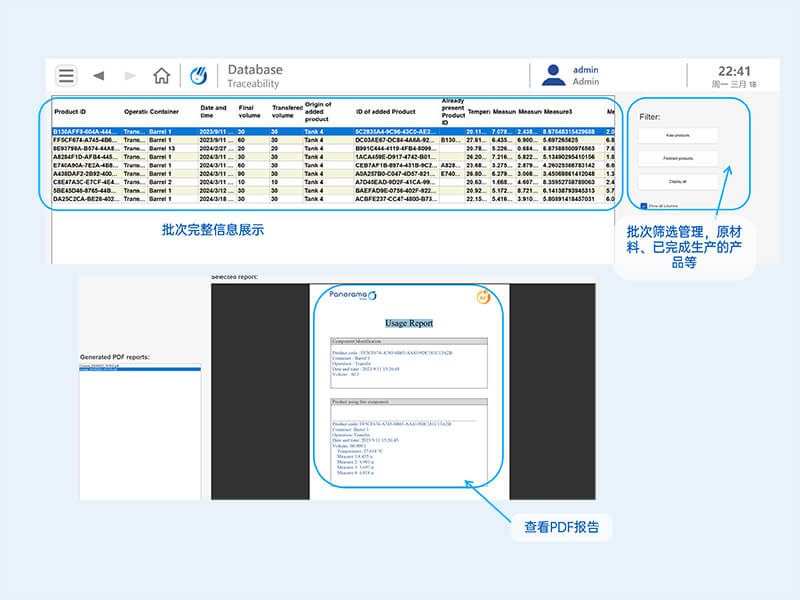

| Batch Management

- Batch full information display

- Batch screening management, raw materials, finished products and detailed data display

- PDF report export, view exported reports

Landing Application showcase

| Pharmaceutical Industry Cases

Sanofi

Background:

The Sanofi Group, which specializes in the key divisions of pharmaceutical manufacturing and packaging, has built a powerful FM/BMS pharmaceutical production management system solution powered by Panorama E2 that meets the Group's energy efficiency needs by displaying information in real time, monitoring and ensuring optimal configuration of building services, and generating reports on energy consumption.

Objective.

- Production of 176 million boxes of tablets and ampoules per year

- Increase in production volume, increase in manufacturing costs

- Customer Goal: Reduce Energy Consumption

Implementation of Panorama E2 - Automated unit real-time management equipment

Benefits.

- Ergonomically correct and consistent gui

- Surveillance adapted to changes and site needs

- Encouraging energy saving figures for 2020 thanks to monitoring - 35Gw/h

| Food Industry Case Studies

Isle of France Co-operative Society

Background:

The Co-operative of the Isle of Lancashire in South France specializes in the collection, storage and conditioning of grain. The company equipped its new plant in Angeville, in the grain silo area south of Paris, with a monitoring system implemented by Ineo Centre Chartres. As silos are subject to increasingly stringent regulations, Ineo Centre Chartres chose the Panorama E2 SCADA software suite developed by Codra to build its food production and processing management system because of its reliability, open design and sustainability.

goal

- Operational and management processes

- User-friendly modernized user interface for the system

Solutions

- Panorama E2 SCADA Solution Secures Processes and Optimizes Production

Benefits

- Improving productivity

- Improve user comfort and safety

crux Value

Free Trial

License-free trial support

Free demo

Compliance

Meets FDA requirements - 21CFR Part 11

Compliance with ANSSI Third Party Network Security Certification - CSPN

Supports multiple architectures

Supports single-station, multi-station, and distributed,

Edge, virtual, etc.

high degree of integration

Customized components

All-in-one functionality

Supports multi-remote management

Desktop, Web, Mobile Client

Remote Access and Management

get started

Provides collection model, data model and graphical model.

Highly Reusable Configurations

Massive Data

Highly scalable

Supports millions of data points

Surveillance

IP Camera Integration

Connection to video surveillance system

Report Function

Data Analysis/Reporting Services

Supports local and cloud deployments

Professional technical support from HONGKEI to help you succeed in your project.

As a provider specializing in machine vision and optoelectronic inspection solutions, Avision is also committed to providing you with a range of paid technical services related to this product, aiming to help you succeed in your project in the most cost-effective way. Please contact us if you need technical services related to this product!