- Home

- Technical Products

Enterprise Cloud IT Solutions

Test Measurement

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Latest Articles

- About Us

EN

EN

VST Gidel Camsim™ Camera Emulator / Camera Emulation Card

Camera Emulator generates CoaXPress and Camera Link video streams and test patterns for testing capture cards or vision/imaging systems.

- Camera signal emulator that simulates all CoaXPress image formats to accelerate image processing development and validation

- Camsim™ camera emulators/camera emulation cards enable most development to be accomplished in a low-cost laboratory environment, significantly increasing productivity and reducing the total cost of developing vision and imaging systems.

- Widely used in vision algorithm development, image processing application testing, vision system reliability testing, debugging rare errors and other projects.

Camsim Camera Emulator / Camera Emulation Card

- The VST Gidel CamSim ™ data stream repetition feature ensures that the algorithm is validated and works as expected with the relevant inputs. In addition, once a rare bug is detected, its respective data stream can be accurately reconstructed to locate the bug and fix it quickly. Its kit includes: application, API methods, PCIe board.

- High DRAM performance up to 24 GB/s, up to 16 x 14.2 Gb/s transceivers (2 for Rx only), up to 10 gb on-board DDR4, up to 98 I/Os

- Emulates all CoaXPress image formats including Mono, RGB, Planar, Bayer, YUV, YCbCr, etc.

- Emulates all Camera Link v2.0 configurations (base/medium/full/80 bits (deca))

- Supports BMP, RAW input image files

- For transmitting color and grayscale test patterns automatically generated by the system.

- Fully programmable image timing and data parameter configuration through a friendly graphical user interface (GUI)

- API Methods for Developing User Simulation Applications

- User configurable camera control (CC) lines, user trigger options

- API Methods for Developing User Simulator Applications

- 1 or 8 GB image buffer

- 4x HD-BNC connectors for emulating up to 4x 12.5 Gb/s cXp links

- Two SDR-26 connectors for simulating all camera modes

Machine Visual System Verification

CamSim is used to validate machine vision systems, such as image quality inspection.

By processing sample images taken in real life, each frame can be accurately reproduced with 100%.

After a processing error is detected, you can repeat this screen until the problem is resolved.

Users can reuse the CamSim test system and compare it with the original design.

Simulation Synchronized Multiphase Acquisition

The CamSim camera simulator synchronizes multiple devices to simulate actual camera operation.

Ideal for applications where multiple targets need to be captured simultaneously, such as 3D reconstruction.

Synchronization can be achieved via external or card-sent triggers.

Boundary conditions for simulation algorithm development

Using the boundary conditions developed by the CamSim simulation algorithm, a test image file (BMP) was created, the

Input to the user system. Users can use the debugging tool to debug problematic image processing.

Flexible characterization of boundary conditions by adjusting image features such as adding noise, gain, etc.

Simulates changing environmental conditions

CamSim provides images of changing environmental conditions, solving the challenges of developmental validation.

Users can adjust the image streaming speed to more easily recognize image processing errors, saving time and costs.

Product Advantages

CamSim Camera Simulator Dramatically Accelerates Image Processing Development and Verification Processes

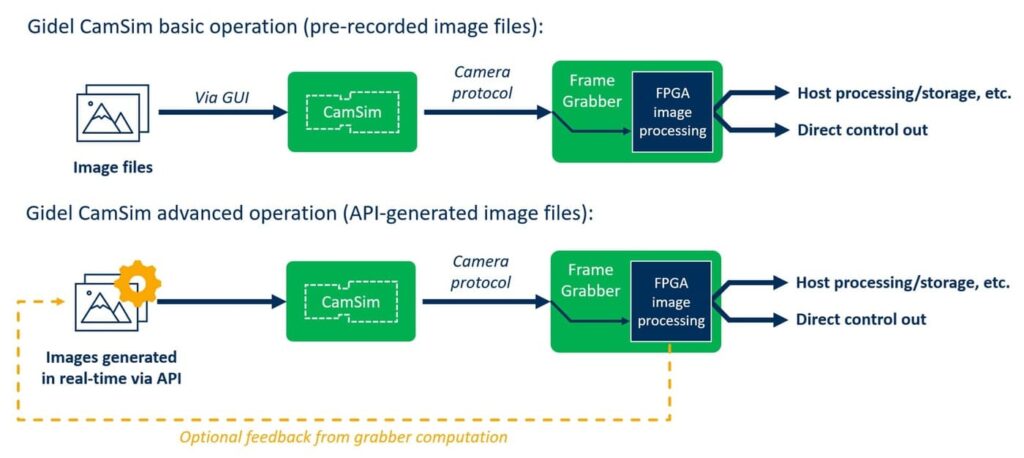

The CamSim camera simulator is capable of generating image data, not only for playing back real image data recorded in previous experiments, but also for creating virtual images for developers.

Its test modes can run at high speed, slow motion or even frame by frame for optimal visualization. Users can generate specialized images based on real images/videos to better validate the algorithm or for debugging.

At the same time, users do not need to set up an environment for the entire system or field testing, but only need a capture card and CamSim simulator to complete the development and validation functions.

CamSim Camera Simulator Kit: Easy Image Simulation and Custom Development

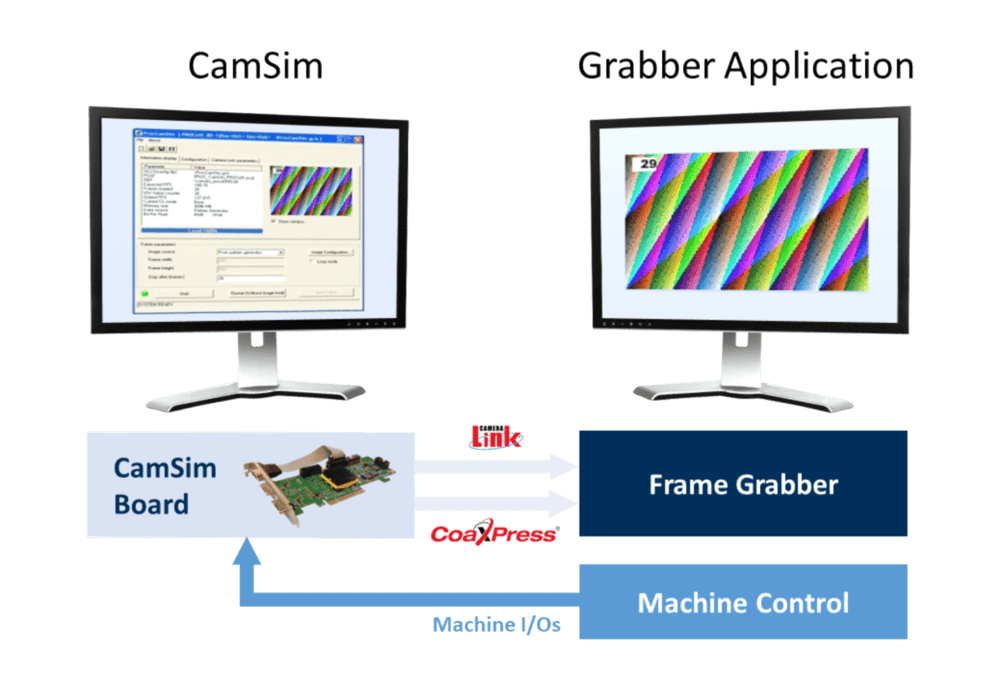

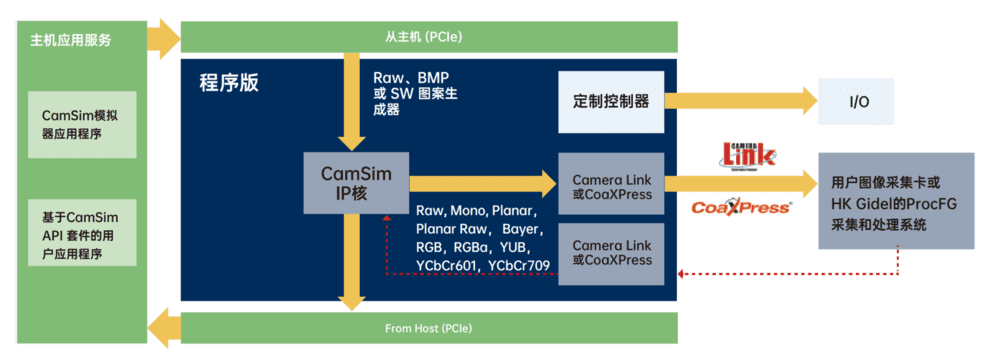

The CamSim camera emulator can be interfaced with CoaXPress, CameraLink, and the user's third-party capture card for user data emulation, and its kit includes:

1. Application software: Intuitive GUI for full control of the image simulation process, including: transferring images from local files or test pattern generator files, configuring Camera Link or CoaXPress parameters, defining signal timing, and displaying transferred images.

2. API methods: A set of Gidel CamSim API methods that can be used to develop customized user applications. The API methods operate on Windows and Linux.

3. Terasic PCIe Board: PCIe FPGA board with Gidel CamSim firmware for transferring video data.

Technical Specifications

Project | parameters | Project

| parameters |

CoaXPress Linking Model

| Up to four 12.5 Gb/s links

| Camera Link Mode | 1 80 bit (Deca), Full, Medium or Base mode |

pixel format | Raw, Mono, Bayer, RGBA (8, 10, 12, 14 and 16 bit/color), RGB (8, 10 and 12 bit/color), YUV, YCbCr601, YCbCr709

| Maximum resolution

| Horizontal: 16 K pixels (24-bit) Vertical: 65 K lines (16-bit) or Infinite in line scan simulation |

Camera Link Configuration | All configurations of Camera Link standard definitions, including 80-bit (Deca): 10 taps/8bits, 8bits/10taps

| Camera Link Pixel Clock | Up to 85 MHz |

motherboard | 4x HD BNC (CoaXPress), 2x SDR26 (Camera Link), 15 pin I/O

| Frame Buffer

| 1 or 8 GB |

Motherboard Form Factor

| Thin Profile PCIe

| Software Support

| HK CamSim GUI, API and Examples |

Mainframe Bus | PCIe x 8 Gen.3

| Camera Type | Line/Surface Sweeps |

Operating System Support | Win 10/11 and Linux (core 2.6.x-5.19)

|

Available Models

Project | parameters |

CamSim-CL

| Output: Single base/ medium/ full/80bit (DECA) 8 or 16 GB image buffer Includes: CamSim board, application GUI and API kit for developing customized applications

|

CamSim-CL-Lite |

Output: Single base/ medium/ full/80bit (DECA) 1Gb Image Buffer Includes: CamSim board, application GUI and API kit for developing customized applications

|

CamSim-X | Output: 4x CoaXPress, 1.25-12.5 Gb/s (CXP-12) 8 or 16 GB image buffer

|

CamSim-X-Lite | Output: 4x CoaXPress, 1.25-12.5 Gb/s (CXP-12) 1Gb Image Buffer |

Technical Support

Professional technical team to serve you: with many years of experience in machine vision and optoelectronic inspection, customized a number of rich and mature landing projects.

Product Catalogs and Data Sheets

Introductory Articles and Cases

App Videos

Professional technical support from HONGKEI to help you succeed in your project.

As a provider specializing in machine vision and optoelectronic inspection solutions, Terasic is also committed to providing you with a series of paid technical services related to this product, aiming to help you succeed in your project in the most cost-effective way. Please contact us if you need technical services related to this product!

Frequently Asked Questions

Technical support and paid services to drive your project to the limit.

CamSim mainly consists of host computer software GUI + hardware FPGA-based development board + user processing API. The CamSim host computer software simulates the test image by auto-generating or PCIe loading RAW image files and BMP image files.

The host computer software application configures all simulation parameters, including timing, resolution, Camera Link or CoaXPress channel structure, etc. The CamSim boss hardware is responsible for receiving image data from the software application and generating data valid signals under the specified timing configuration. The CamSim boss card hardware is responsible for receiving image data from the software application, generating data valid signals under the specified timing configuration, reconstructing and outputting image data corresponding to the Camera Link or CoaXPress configuration, and communicating serially with the video capture card.

Currently, the single-boss card only supports single-base mode, if users need to realize dual-base, they can use two CamSim boss cards to realize this function.

Images are first preloaded from the computer's RAM into CamSim's on-board memory and then transferred from CamSim via the CameraLink/CoaXPress interface. 1GB and 8GB are the CamSim on-board memory, which define the total size of the image buffer that can be preloaded onto the board. The larger the buffer, the more images can be loaded onto the CamSim board for camera simulation. How many images can be loaded depends on the size and format of the images.