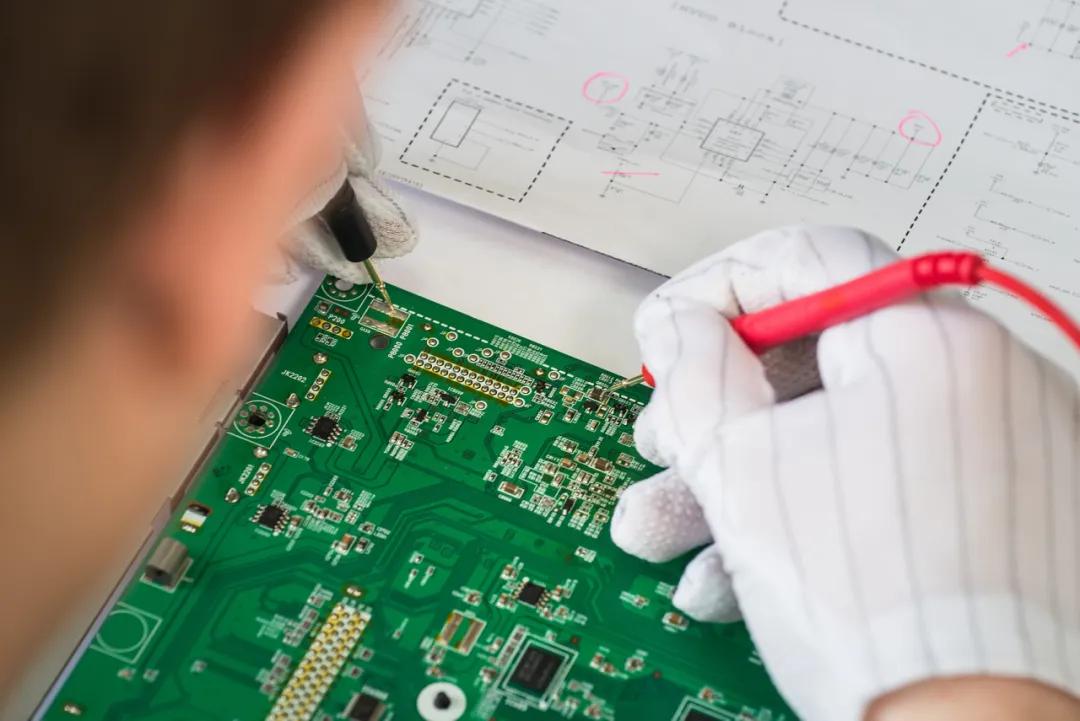

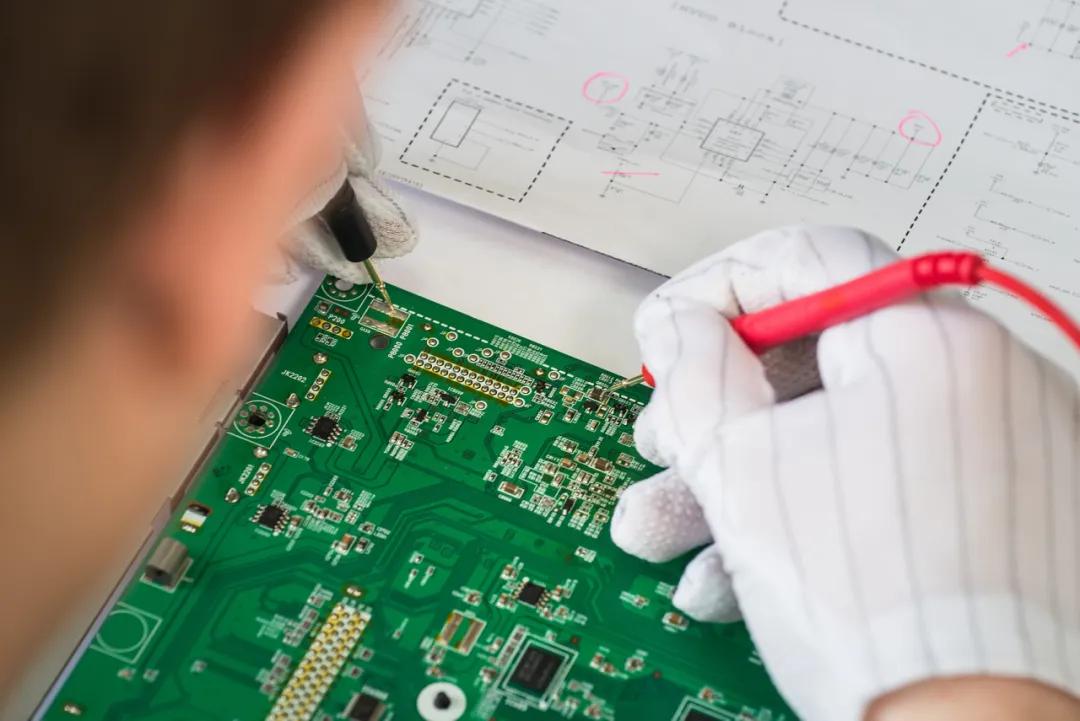

【虹科方案】AI+AR 重塑 PCB 質控流程|虹科 AR 智慧質檢解決方案

虹科結合 AR 智慧眼鏡與 AI 辨識技術,打造標準化 PCB 質檢工作流程,整合 MES、ERP、AOI 系統,降低漏檢率、提升良率,加速電子製造數位化升級。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Based on Hongke's GNSS simulator technology solution and combined with actual application scenarios, this paper demonstrates the core value of this system in the development of new generation of inspection UAVs (unmanned aerial vehicles), covering a full range of testing capabilities in terms of navigational accuracy, multi-constellation compatibility, interference immunity and multi-sensor fusion performance.

A UAV R&D company needs to complete the testing of a new generation of inspection UAVs, and the testing requirements include:

The test must validate the UAV in a complex environment:

Field testing has long been constrained by the following factors:

This makes it difficult to meet the high efficiency and consistency of R&D needs.

To avoid these limitations, companies ultimately use Laboratory GNSS Simulation Test SolutionThe test platform is automated by HONGKE for full-scene coverage and high-precision validation.

GTS-P7 Built on the Skydel software engine, it provides a one-stop, high-performance, software-defined architecture for GNSS signal testing.

Key features include:

Skydel offers superior software definition flexibility:

The HONGKE Platform supports deep integration with a wide range of standard authentication tools:

All testing is done in the lab, no actual UAV flights are required. Controlled and highly reproducible

| Test Item | Test Content | Test Objective |

|---|---|---|

| 1. Static calibration | Simulated elevation angle 0°-90°, adjusted constellation signal strength -130 dBm to +20 dBm | Cold start positioning RMS < 1m |

| 2. Dynamic flight | Generates S-shape, sharp turns (radius <10m), ±5g vertical dynamics | Verification of DOP stability and heading error under high dynamics |

| 3. anti-interference test | Output Narrowband / Wideband / Pulse Interference | Verify Location Availability and Resilience |

| 4. RTK accuracy test | Analog Base Station - Mobile Station Differential, Delay | Verification of RTK cm-level positioning stability |

✓ Multi-constellation free switching (GPS / BDS / GAL / GLO)

✓ Pseudo-distance accuracy ≤ 1 mm

✓ Supports multiple interference signal overlays

✓ Support for forged coordinates and spoofing emulation

10 typical scenes in one go

→ Field Requirements 10 days → Laboratory only 8 hours

Failure can be reproduced by 100%

→ Support for track playback and pinpointing problem sources

Airspace Application Fee ↓ 90%

Field labor + Depreciation of equipment ↓ 40%+

Shorter test cycle 70% Above

Simulation of mountain terrain → Verification of power line obstacle avoidance

Testing of GNSS post-loss IMU takeover capability

Joint testing with 5G return link (<50ms)

GNSS + IMU + Visual SLAM Multi-sensor Fusion Verification

虹科結合 AR 智慧眼鏡與 AI 辨識技術,打造標準化 PCB 質檢工作流程,整合 MES、ERP、AOI 系統,降低漏檢率、提升良率,加速電子製造數位化升級。

深入解析虹科 GNSS 模擬器如何支援無人機整機測試,涵蓋多星座 GNSS 仿真、RTK 公分級定位、抗干擾測試與多感測器融合驗證,助力高效、安全的 UAV 研發。

增材製造(PBF-LB/M)中的高精度過程監控與誤差檢測,虹科 iDS USB3 工業相機助力粉末層、再熔化層與動態飛濺監控,提升部件品質與研發效率,適用航空航天、醫療、汽車等行業。