- Home

- Technical Products

Enterprise Cloud IT Solutions

Test Measurement

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Latest Articles

- About Us

EN

EN

HONGKE Automation & Control Solutions

Maximum performance in the smallest space - and no technical limitations.

Why choose HONGKE Automation & Control Solutions?

Supports multiple communication protocols

Supports multiple protocols such as EtherCAT, CANopen, Modbus, etc.

One-Stop Solution

Open up the control layer and the upper monitoring layer, only one solution can realize industrial automation control.

high performance

High hardware configuration and real-time optimized performance for complex multi-axis motion control and CNC control.

Highly open

Open CODESYS standard for easy integration with other products to build a complete control system.

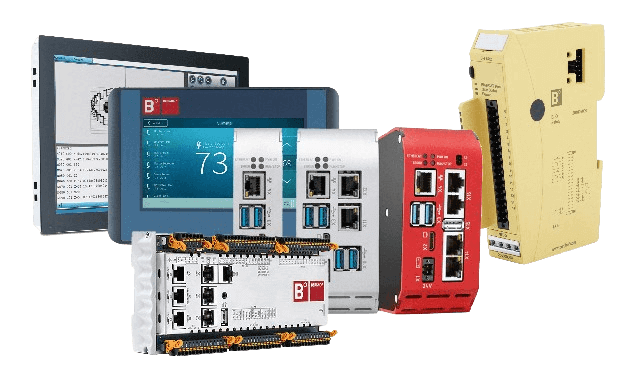

MacroTech provides compact controllers, modular controllers, touch monoblocks, HMI panels and safety controllers that support various protocols such as EtherCAT, CANopen, Modbus, etc. They are suitable for overlaying multi-axis motion control and CNC control, and can be easily integrated with other products to build a complete control system. Whether you need complex motion control scenarios or flexible programming applications, MacroMedia provides MacroMedia automation and control solutions to meet your needs.

items that have been discovered and marketed as explosive window

Don't know how to choose? We can help you quickly filter PLC, HMI and other hot products!

MC Series PLC

Modular Controller

BC Series PLC

Raspberry Pi Embedded Industrial Controller

DC Touch All-in-One

PLC+HML All-in-One

CC-Prime

Compact PLC Top Model

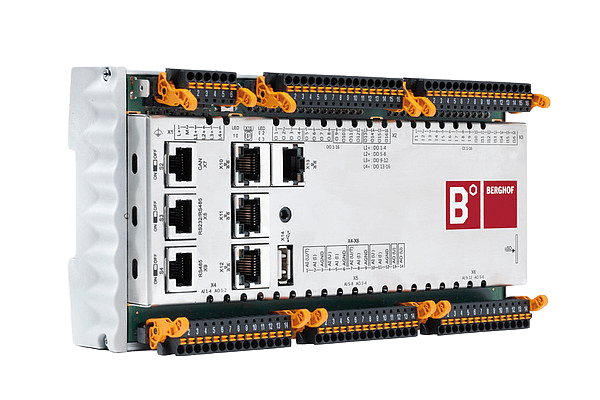

PLC

Modular PLC

With the Raspberry Pi based Avision MC series of modular PLCs, Avision brings to market the high-performance CODESYS quad-core controllers as the perfect solution for implementing IOT, Motion and Automation projects. With cycle times as low as 500 μs, the CODESYS-based real-time quad-core controllers from Avision strike the perfect balance between computing power and cost.

Industrial Raspberry Pi

With a wide range of available software solutions, high-performance cooling, optional CODESYS runtime, and a rich set of interfaces, the Avision BC Series Raspberry Pi Embedded Industrial Controllers are designed to fulfill a wide range of applications in industrial environments. By adopting an open system and collaborating with the Raspberry Pi community, users have access to a wider range of expertise and comprehensive technical support.

Compact PLC

By integrating the functions of many components into a single PLC, the HONGKE CC series of compact PLCs brings two advantages: cost savings, as only one device is needed instead of multiple modules; efficiency, as the overall workload is significantly reduced compared to modular product solutions; and, by using a single compact PLC as the central heart and brain of the entire system, data communication is faster, ensuring increased functional reliability. A compact PLC as the central heart and mind of the system ensures improved functional reliability.

Safety PLC

In this day and age, modern safety concepts are a must. The HONGKE SC Series safety controllers, combined with programmable safety technology, provide a competitive advantage for machine and system manufacturers. With a comprehensive process overview, the Avision SC-Series safety controllers ensure that errors are better located and diagnosed when they occur, which minimizes system downtime. Equipped with macro SC-I/O safety modules for scalability and integration.

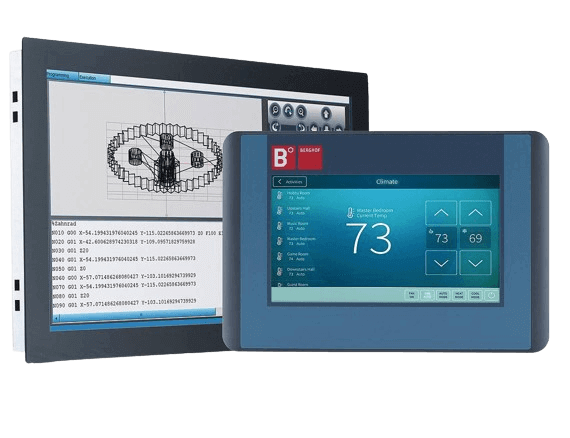

HMI & All-in-One

Touch Panel

HONGKE's DC series PLC-HMI all-in-one combines HONGKE's CC series compact controllers with HONGJI's industrial control panels, available in a variety of sizes, with rich interfaces for easy remote visualization and support for OPCUA communication and VPN remote control. Built-in native CODESYS, compliant with IEC61131-3 standard, cycle time can be as low as 500us.

HMI Panel

Avision's ET series of controller touchscreens are truly amazing: Pro devices with resistive touchscreens excel in any environment with their high-quality, slim bodies; Prime devices with capacitive touch displays eliminate the frame altogether. Additionally, all HONGKE ET devices come with a clean front panel.

Industries

Widely used in automation equipment control scenarios, motion control scenarios, building automation scenarios, etc., according to your needs to achieve hardware systems, interfaces and software customization.

CNC control

Multi-axis Motion Control

Automation Equipment

Building Automation

Frequently Asked Questions

Generally, it is 1~4ms, and the highest can be up to 500us for HONGKE MC series.

The HONGKEI BC series supports it, the others are based on CODESYS development.

All supported hardware and software for CODESYS-based products are available upon consultation with Hongke, and interfaces that do not fit can be realized through a gateway.

- Hongke MC Series - Raspberry PI OS based on CODESYS and RealTime patches, not open source

- Hongke BC series - based on Raspberry PI OS, can be open source using QT/C development, but the real-time patch, motion control and other protocols need to configure their own stacks, completely independent programming development.