【虹科方案】從被動防禦到主動預防:用 KnowBe4 輕鬆應對關鍵基礎設施條例風險評估與審核

KnowBe4 為企業應對香港《關鍵基礎設施保護條例》提供了化繁為簡的解決方案。面對第 24 條與第 25 條的嚴格挑戰,它將難以量化的「人為風險」轉變為可追蹤的實戰數據,不僅彌補了傳統評估的盲點,更為年度審核提供了證明控制措施「有效運作」的鐵證。透過自動化報告與持續演練,企業能在大幅降低安全風險的同時,輕鬆滿足監管要求,實現從「被動合規」到「主動防禦」的關鍵轉型。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Wafer transportation is a critical and sensitive part of the semiconductor manufacturing process. To ensure product quality and yield, a number of conditions must be strictly controlled during wafer transportation, including ESD protection, vacuum environment, temperature and humidity control, vibration protection and transportation tracking. The following are the five key points of attention:

Wafers are highly susceptible to static electricity and therefore require strict ESD protection during transportation. It is necessary to useAnti-static packaging materials, conductive insoles and anti-static clothing, and avoid static-generating behaviors.The wafer surface should be protected from damage.

To prevent contamination of wafers with dust and particles, transportation must be performed under clean and vacuum conditions. The following should be usedWell-sealed transportation containersThe wafer quality is ensured by avoiding any collision or vibration.

Wafers are extremely sensitive to environmental changes. It is necessary to use constant temperature and humidity transportation equipment to move theTemperature and humidity remain within a stable rangeIt prevents microstructural damage caused by heat expansion and contraction or moisture.

Wafers are brittle materials and can be ruptured by the slightest vibration. Therefore, high shockproof packaging materials and cushioning structures must be used in transportation, andAvoid rough handlingto ensure integrity.

To ensure that the entire transportation process can be tracked and monitored, it should beConfiguration of a complete logging systemIt includes information such as temperature and humidity, position, vibration and time, etc., so as to quickly grasp the status of goods and immediately respond to abnormalities.

As a result, wafer transportation requires extremely high levels of control and protection to ensure that wafer quality and integrity are not compromised.

MSR175Plus Shock Vibration RecorderHONGKE is a monitoring device designed for high-end manufacturing and precision logistics scenarios, specialized in monitoring and recording the transportation process.Temperature, Humidity, Pressure, Acceleration and Geographic LocationThe data is not available for the first time, but for the second time, it is available for the second time.

built-in GPS Positioning ModuleIt can accurately record the real-time location of goods in transit and upload the data to a computer or mobile device via wireless transmission for subsequent analysis and evaluation.

The MSR175Plus is especially suited for use in logistics, manufacturing and international transportation, especially where long distance transportation or temperature and humidity monitoring in special environments is required. With real-time monitoring, temperature and humidity changes and vibration shocks can be accurately tracked, ensuring that the product remains in optimal condition throughout the supply chain.

The device has extremely high measurement accuracy and stability, and provides detailed graphical data reports for easy analysis and comparison. The rugged casing is designed to withstand harsh transportation conditions, and the long battery life supports long-term monitoring to ensure uninterrupted transportation throughout the entire process.

With the MSR175Plus, companies can control key parameters during transportation, preventing quality risks and ensuring product safety. This device is especially suitable for industries that require strict monitoring, such asSemiconductor, Pharmaceutical, Biotechnology, Food and High-end Precision Manufacturingetc.

The MSR175Plus is a highly functional GPS Shock Vibration RecorderThe newest addition to our line of products is the newest addition to our line of products, which provides a comprehensive solution for transportation monitoring. It simultaneously monitors temperature, humidity, pressure and vibration to ensure optimal quality and safety during global transportation.

A1:We apply the MSR175Plus to cross-country transportation between Taiwan and the United States. Since vibration occurs in multiple directions during transportation, we need to accurately grasp the actual g-value and set the maximum vibration tolerance.

On average, a round trip takes about 9 daysTotal distance 25,000 kmThe

A2:Due to the need for long distance testing, the MSR175Plus is equipped with the following features High-capacity battery and large memory spaceThe HK-MSR175Plus is designed to be a reliable and stable device for long term measurements. The HK-MSR175Plus can avoid the problem that some products may lose data due to insufficient capacity under long term recording.

A3:With the MSR175Plus, we are able to better understand the actual effect of vibration on the mask and establish a quantitative standard, which will help prevent potential risks in the future, and significantly improve the success rate of mask transmission and quality stability.

A4:In the future, photomasks will continue to be equipped with the MSR series of recorders for round-trip transportation between Taiwan and the U.S. in order to monitor vibration conditions and continuously optimize transportation standards.

A5:The MSR175Plus is an indispensable professional monitoring tool for any company or engineer who needs to "quantify vibration data".

KnowBe4 為企業應對香港《關鍵基礎設施保護條例》提供了化繁為簡的解決方案。面對第 24 條與第 25 條的嚴格挑戰,它將難以量化的「人為風險」轉變為可追蹤的實戰數據,不僅彌補了傳統評估的盲點,更為年度審核提供了證明控制措施「有效運作」的鐵證。透過自動化報告與持續演練,企業能在大幅降低安全風險的同時,輕鬆滿足監管要求,實現從「被動合規」到「主動防禦」的關鍵轉型。

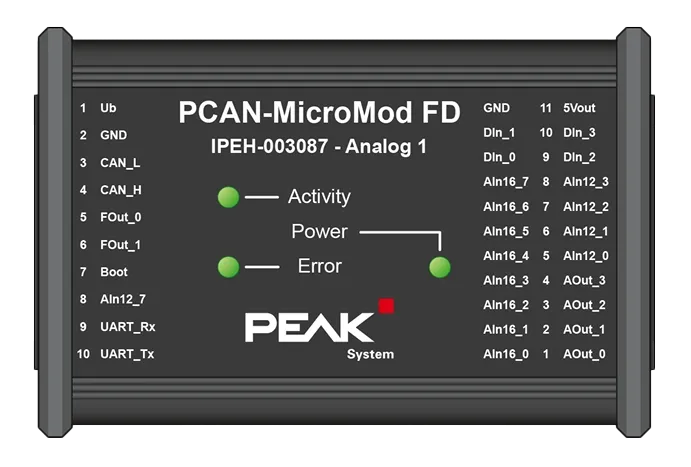

安鵬精密於實際 NVH 路測中,透過虹科 PCAN-MicroMod FD,將車輛 CAN / CAN FD 訊號即時轉換為類比電壓,無需二次開發即可完成訊號同步,低成本整合既有 NVH 資料採集系統。

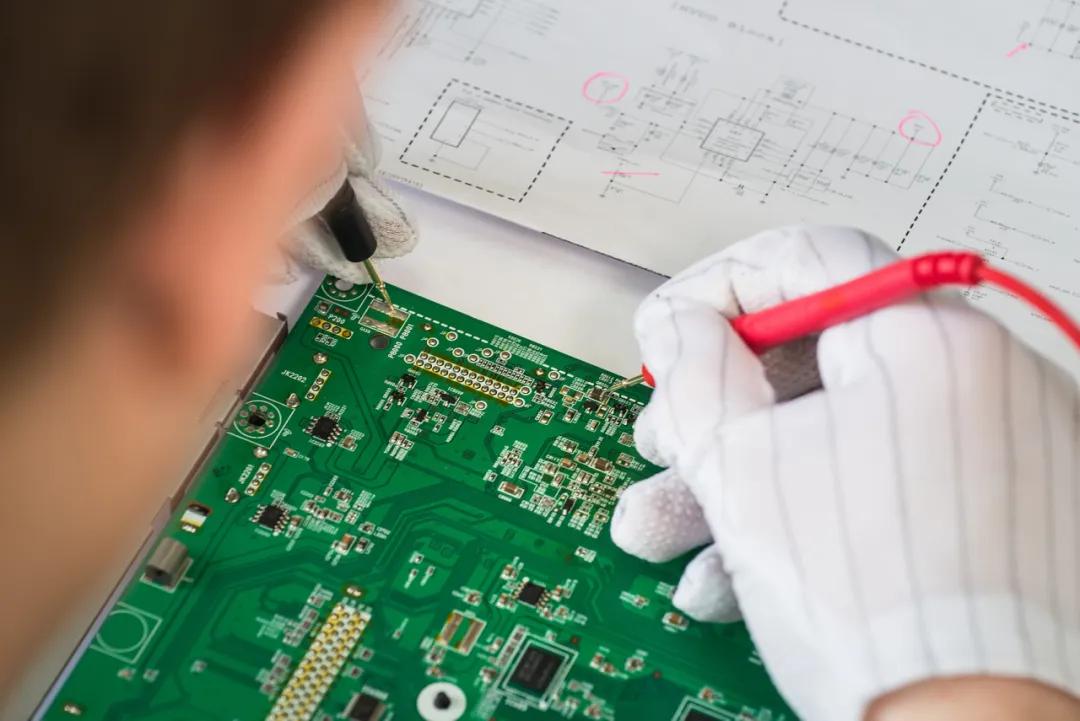

虹科結合 AR 智慧眼鏡與 AI 辨識技術,打造標準化 PCB 質檢工作流程,整合 MES、ERP、AOI 系統,降低漏檢率、提升良率,加速電子製造數位化升級。