- Home

- Technical Products

Enterprise Cloud IT Solutions

Test Measurement

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Latest Articles

- About Us

EN

EN

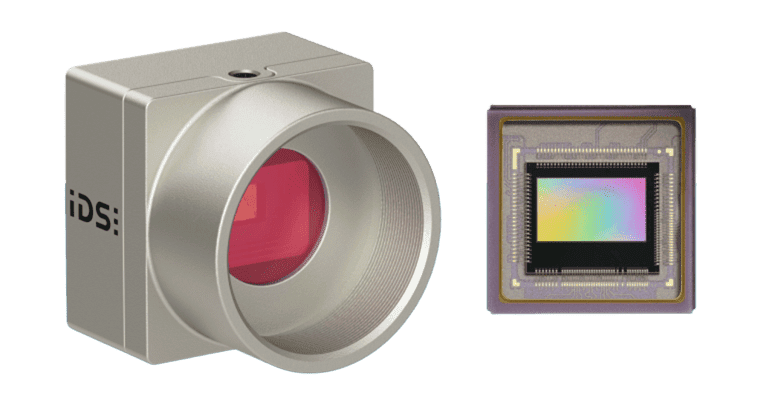

uEye XCP-E | XLS-E EVS Event Camera

Industrial cameras with event-based vision sensors for less data, more speed, and more accuracy

Launched by IDS in cooperation with Sony and Prophesee, the EVS event camera is equipped with event-based sensors that recognize only the contrast changes of each sensor pixel, which are transmitted in real time as independent events, while static data is completely omitted, allowing for extremely fast detection processes, high dynamic range, direct access to the results instead of the raw data, and high data processing throughput. The data is processed in a small amount, efficiently and accurately. It is very suitable for a variety of applications in the industrial field, such as high-speed moving object counting and inspection, equipment vibration monitoring, motion monitoring and analysis, and image recognition.

uEye XCP-E XLS-E | EVS Event Camera

Product Selection

Product Selection

Core advantages

Core Strengths

Application scenarios

Application Scenarios

Application case

Client Cases

Technical Resources

Technical Resources

Event-based visual sensors (EVS)

Event Based Technical Principles

Only detects pixel variations:Developed by iDS, Sony and Prophesee, unlike traditional frame-based industrial cameras that generate complete megapixel image data, the uEye EVS recognizes only the relative change in pixels per sensor. This means it can capture the trajectory of moving objects with very high temporal resolution, no longer capturing static and irrelevant backgrounds, and with 10 to 1,000 times less data than frame-based image sensors.

Event Generation and Scene Driving Features:1280 x 720 asynchronous intelligent pixel events with 1µs time resolution for high-speed imaging at 10,000 frames per second.

Adapts to changes in extreme light:No exposure time is required, capturing dynamic scenes without blurring with 120dB high dynamic range and 40mlux high sensitivity, pre-sorting at the pixel level, speed and robustness to complex lighting conditions, and motion understanding.

System power consumption and computing power requirements are minimal:Based on the neuromimetic vision technology, the energy consumption and computational power requirements of the machine are greatly reduced, with average energy consumption in the mW range.

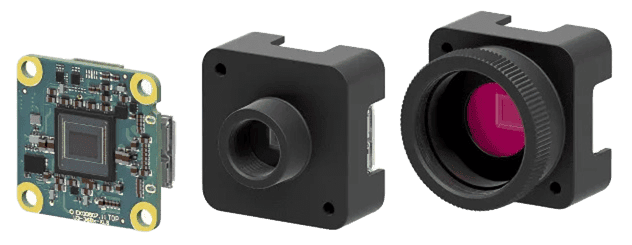

uEye XCP-E: IDS's smallest size event-based industrial camera

The compact die-cast zinc housing (29 × 29 × 17 mm) is small and lightweight, comes with a lockable USB-Micro-B connector, and is compatible with all common C-mount lens sizes.

It can be used in conjunction with Metavision SDK software for identification processing systems to improve the efficiency of data processing for both industrial and non-industrial applications.

uEye XLS-E: Event-Based Board Camera for Embedded Applications

Ultra-compact board-level camera (29 × 29 × 7 mm), can be quickly and directly into the lens holder, low heat generation, very suitable for embedded applications

SuperSpeed USB3 camera with Micro-B connector, with or without C/CS or S-mount lens mount, can be combined with Metavision SDK software for recognizing processing systems.

Product Composition and Core Strengths

Product component and core advantages

Ultra-high-speed process precision capture

With a temporal resolution of less than 1μs, uEye EVS captures extremely fast motion without motion blur and eliminates "blind spots" between images at a frame rate of over 10,000 FPS.

Extremely high dynamic range with no fear of light or dark

The uEye EVS utilizes Sony's IMX636 pixel technology, which recognizes contrast changes at 0.08 lux in near-lightless environments, and logarithmically handles high light values. uEye EVS surpasses the sensitivity of traditional image sensors in extremely bright scenes, providing clear images in both bright and dark environments.

Get results directly instead of raw data

Inspired by human vision, Sony and Prophesee's neuromorphic sensing technology captures only pixel motion, transmits the data with attached coordinates and timestamps, and outputs usable results directly instead of raw pixel brightness values.

Efficient data processing

uEye EVS captures only dynamic changes and ignores static areas, significantly reducing the amount of data to be processed and saving memory and computation time compared to traditional image cameras.

Extremely fast detection process

Extremely high dynamic range

Results instead of raw data

Efficient Data Processing

Application Scenarios

Application scenarios

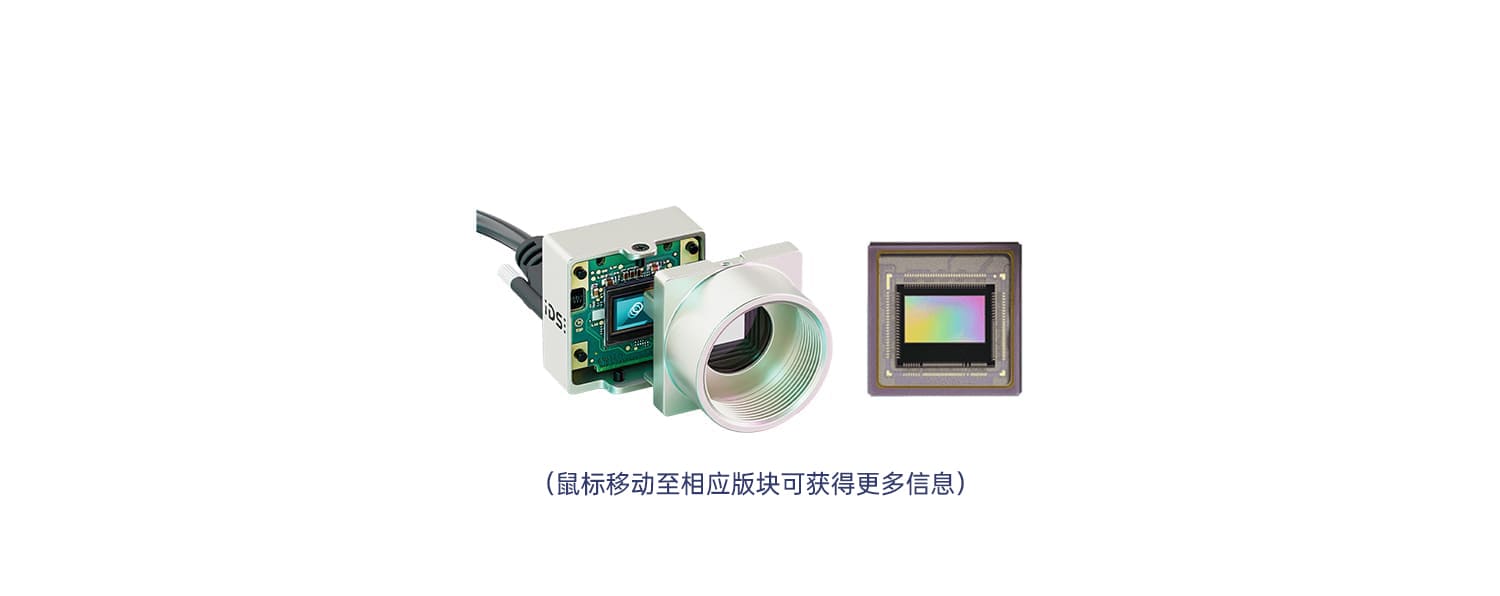

Sony Prophesee IMX636 Sensor

- 1280 x 720 asynchronous smart pixels

- Sensitivity up to 40 mM, 120 dB HDR

- Scene control events with 1µs time resolution

- Variable data volume (10 to 1000 times less than image sensors)

Motion monitoring (high-speed motion capture)

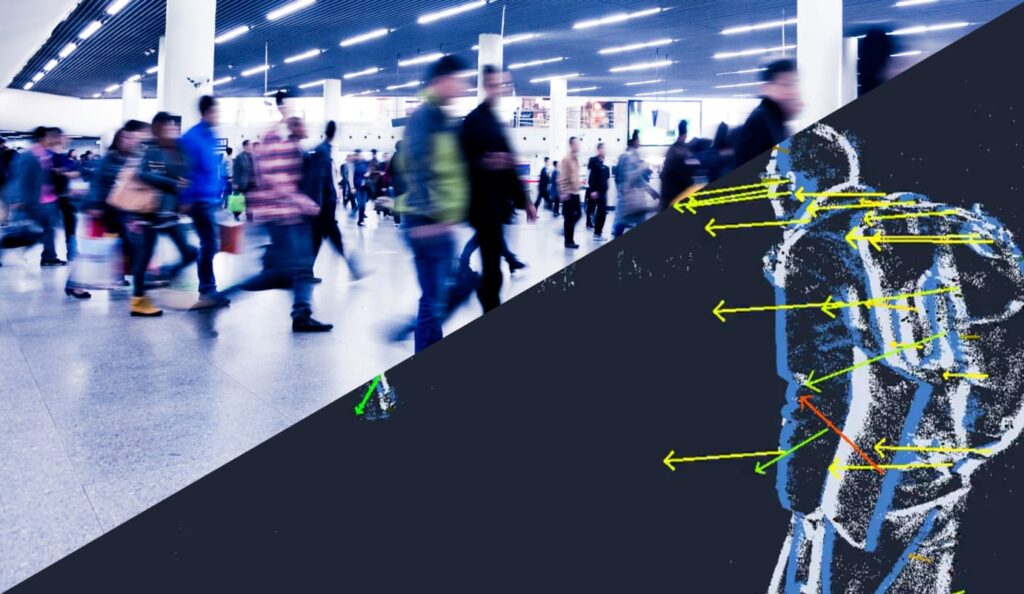

Crowd monitoring and tracking (capturing the direction and path tracking of human movement)

High-speed pick-and-place positioning/guiding/assembly (μs time resolution without motion blur)

Fluid dynamics monitoring (continuous process tracking of flow, 10,000+ FPS capture details)

High-speed pick-and-place positioning/guiding/assembly (μs time resolution without motion blur)

Fluid dynamics monitoring (continuous process tracking of flow, 10,000+ FPS capture details)

Splash Monitoring (Industrial Application Analysis)

Mass prediction (tracking of small particles with splash-like motion)

Traditional milling/laser process monitoring (tool/beam vibration waveform identification)

Traditional milling/laser process monitoring (tool/beam vibration waveform identification)

Online particle/object size monitoring (high-precision distribution measurement)

High-speed counting (real-time counting of pharmaceutical tablets)

High-speed measurement of the size of the target object (real-time measurement of the size of a high-speed moving object in the channel/transfer belt)

High-speed measurement of the size of the target object (real-time measurement of the size of a high-speed moving object in the channel/transfer belt)

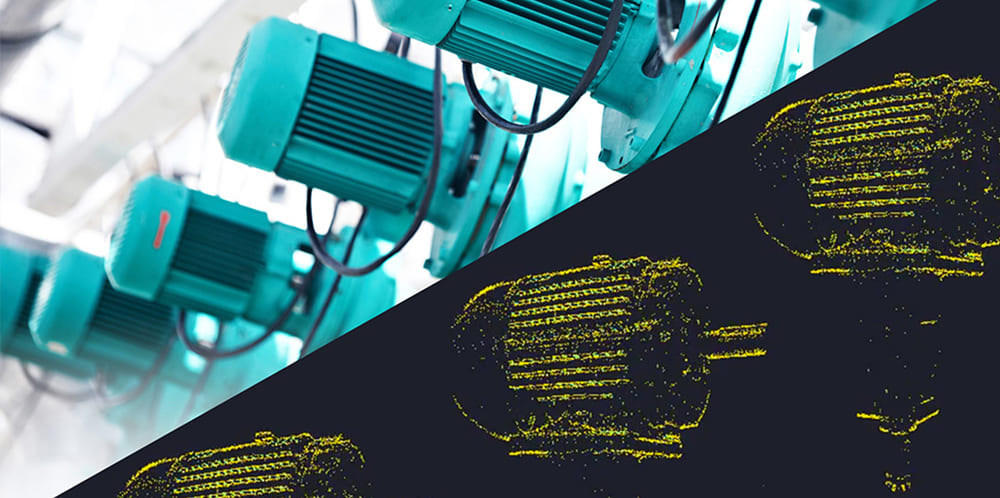

Predictive maintenance (frequency domain analysis)

Vibration mode detection of mechanical components (e.g. early abnormal vibration capture of motor bearings)

Equipment health monitoring (periodic frequency anomaly detection based on vibration/motion events)

Equipment health monitoring (periodic frequency anomaly detection based on vibration/motion events)

Customer Examples

Application case

100 μs

Time resolution less than

10,000 FPS

Frame rate capture

0

Motion blur

120 dB +

Dynamic range

Vibration monitoring applications for industrial equipment

Customer Needs:Vibration monitoring of industrial equipment (e.g., large machinery, fans, pumps) is crucial for predictive maintenance. Traditional frame-based cameras have three major limitations: (1) insufficient frame rate leads to loss of high-frequency vibration signals (affecting the accuracy of fault diagnosis); (2) high frame rate generates massive amounts of data (increasing storage/processing costs and system complexity); (3) reduced imaging quality in complex lighting environments (decreasing the reliability of monitoring).

Solution:The event camera continuously monitors vibration frequency through pixel-level tracking (recording coordinates/polarity/timestamps), analyzes vibration patterns in real time, detects anomalies at an early stage and supports predictive maintenance, reduces downtime and spare parts costs, and improves equipment reliability.

More application examples:

- High Speed Counter

- Analyze the frequency and mode of vibration

- Ultra-slow motion for analyzing the finest motion dynamics.

0.08 lux

Contrast Change

Extremely high dynamic range

Capture information in real time

Dimensional quantity deviation

Particle/object size monitoring and high-speed counting

Customer Needs:On production lines in manufacturing industries, such as electronic component production, pharmaceutical industry, food processing, etc., there is a need for precise size control, real-time technology and measurement of objects moving at high speeds in channels or conveyor belts, such as ensuring that the dimensions of parts are in accordance with standards, or strictly monitoring the size of pharmaceutical pills. Conventional measurement and counting methods may have problems such as slow measurement speed, lack of accuracy, and inability to process in real time.

Solution:Event vision sensors with high temporal resolution and dynamic range, the sensor can accurately measure the dimensions of individual objects on a high-speed production line and provide real-time quality statistics and counting information during the production process, helping customers to detect dimensional deviations and quantitative discrepancies in a timely manner to ensure product quality and production efficiency.

More application examples:

- Process monitoring under photocopying conditions

- HDR Driver Assistance System

- "Image + Event", RGB and EVS camera synchronization, high-speed shooting of clear images even in poor lighting conditions

Get Direct Results

High time resolution

High dynamic range

No chemical analysis required

Plume/Fluid Dynamics Monitoring

Customer Needs:In industries such as food and beverage production, oil and gas transportation, and biotechnology manufacturing, there is a need for real-time monitoring of continuous liquid flow, as well as the detection of abnormal fluid dynamics due to residue buildup, spot contaminants, or unwanted air or air bubbles, such as ensuring the accuracy and stability of liquid filling, and monitoring the state of the oil stream to prevent leakage and clogging. Traditional monitoring methods often rely on chemical analysis, which has a slow response time and cannot meet the demands of real-time production monitoring.

Solution:Event-based optical flow technology enables real-time fluid monitoring, providing immediate feedback on fluid health and behavior by analyzing light change events during fluid flow. The method quickly identifies process interruptions that affect yield without waiting for chemical analysis.

More application examples:

- Tracking Mobile Objects

- Analyzing the motion of the smallest particles

Capture only changes

Ignore static areas

Capture the edge with precision

Tracking Data Stabilization

Followed by EDGELET

Customer Needs:In the fields of 3D modeling, VR, AR application development, and industrial inspection, it is necessary to accurately track the edge characteristics of objects. For example, accurately capturing the edges of objects to generate highly accurate models, and real-time tracking of baseline markers in the environment to realize the fusion of virtual and real. Customers need a solution that can improve the accuracy and robustness of edge tracking applications. Traditional edge tracking methods may be affected by factors such as light variations and motion blur, resulting in reduced tracking accuracy.

Solution:The Event Camera has a high temporal resolution and is capable of accurately capturing events that change the edge of an object. By tracking 3D edges and datum markers in AR/VR applications, the sensor provides more accurate and stable edge tracking data, maintaining high accuracy even in complex environments.

More application examples:

- Native motion segmentation supports embedded motion analysis

- Continuous Traffic Data Collection

Technical Resources

Technical Resources

Since 1997, iDS has been committed to the development and production of industrial image processing products. With a visionary approach to technology and a keen eye for the future, iDS continues to keep abreast of current trends and innovatively transforms key consumer-grade technologies to meet the needs of industrial applications: it is iDS that has made the USB interface the dominant and highly compatible type of interface in the industrial camera industry.

"The event-based camera achieves excellent time resolution down to the microsecond level, ideal for highly dynamic scenes. The ability to capture rapid object motion provides the best prerequisites for dynamic monitoring while avoiding the unavoidable loss of information associated with traditional image-based sensors."

-Patrick Schick, Product Owner, 3D and Visual Software, IDS.

As a long-term partner of iDS, Terasic has been committed to providing state-of-the-art machine vision technologies and solutions to customers in the Greater China region. Since the establishment of the strategic partnership, Terasic has been providing superior products and services to meet the ever-growing and changing market needs of various industries, and working together with iDS to promote the development of the machine vision field. For event cameras, iDS team can provide you with product selection, one-stop solution design, testing and other technical services, welcome to contact iDS staff for more information.

Professional technical support from HONGKEI to help you succeed in your project.

HongKe provides professional IDS industrial cameras and 3D imaging solutions, including uEye CMOS, NXT AI smart cameras, Ensenso 3D series and event cameras. The cameras are equipped with high sensitivity, low latency, and accurate image processing capabilities, and support various interfaces such as GigE and USB3.0, which can satisfy a wide range of applications such as machine vision, intelligent manufacturing, medical imaging, and automated inspection. With flexible development interface and strong software support, IDS cameras help enterprises build efficient and stable image recognition and AI vision systems, and become the key eyes of the new generation of intelligent industries.