【虹科方案】虹科 AR 遠程醫療解決方案 – 整合 AI 翻譯與遠程會診,推動跨國醫療合作

虹科 AR 遠程醫療解決方案整合醫療級 AR 智慧眼鏡、AI 即時翻譯與遠程會診技術,支援跨語言醫療溝通、臨床教學與國際醫療合作,推動智慧醫療流程數位化升級。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

In the process of smart manufacturing transformation, the site for equipmentFlexibilityandInformation in real timeThe traditional fixed HMI (Human-Machine Interface) is gradually showing limitations in terms of operational convenience, safety and multi-device management. Traditional stationary HMI (Human-Machine Interface) is gradually showing limitations in terms of ease of operation, safety and multi-device management - engineers cannot move freely, debugging requires repeated trips, and device information cannot be synchronized across regions.

To address these pain pointsHONGKE EXOR Launch of the new generation X-Series Mobile Handheld HMIThe concept of "Mobility, Intelligence, and Security" has been put into practice, allowing human-computer interaction to move from fixed screens toA New Era of Freedom of ControlThe

In automated equipment manufacturing or complete production line applications, operators are often required to switch, monitor and commission multiple machines.

Hongke EXOR X Series Mobile HMIs Supports one machine to connect to multiple base stations, flexible switching of control objects, without the need to configure additional operating panels for each device, realizing "one machine, multiple control".

With only one X-Series machine, operators can freely switch between multiple production lines for process adjustment, program download and real-time monitoring.

For packaging, filling, inspection, or assembly lines consisting of multiple modules, users can always bring the HMI to key nodes to perform local operations or maintenance.

This kind ofMulti-purpose"The 'live' mode of operation not only reduces the cost of hardware investment, but also makes the on-site operation process more intuitive and efficient.

In the field of intelligent logistics, warehousing and material handling, equipment such as AGVs (Automated Guided Vehicles), transport robots and elevating platforms are becoming more and more popular. These equipments have their own mobile attributes, and the traditional fixed control panels can no longer meet the needs of operators for real-time control and monitoring at different locations.

HONGKE X-Series Mobile Handheld HMIs passable Wireless or PoE Stable communication with multiple mobile devices. Built-in emergency stop button and Dual-channel secure signal (Black Channel) transmission technologyThis ensures that the absolute safety of equipment and personnel is maintained during wireless operation.

Engineers can move freely around the plant with the handheld HMI to monitor the operation status of the AGVs, and quickly make route adjustments and troubleshooting.

In multilevel stacking systems, handheld HMIs allow operators to set up and operate in the field without having to climb up or return to the control room.

Through X-Series Mobile HMIThe logistics and warehousing companies can truly realize the "TheMotion Control × Security Collaboration"It also enhances the flexibility of system scheduling and maintenance efficiency.

For manufacturers of large-scale automation equipment, the sheer size of the equipment, complexity of the structure, and dispersed points of operation often result in lengthy commissioning and maintenance processes. Engineers have to go back and forth between the front and back of the equipment to confirm status, modify parameters, and observe actions - time-consuming and potentially risky.

Hongke EXOR X Series Handheld HMIs The perfect solution to this pain point:

Field engineers can carry the X10 HMI directly to the end of the production line or module area for process optimization without having to return to the control cabinet repeatedly.

When an alarm or abnormality occurs during operation, you can immediately check the source, adjust parameters, or perform reset operations.

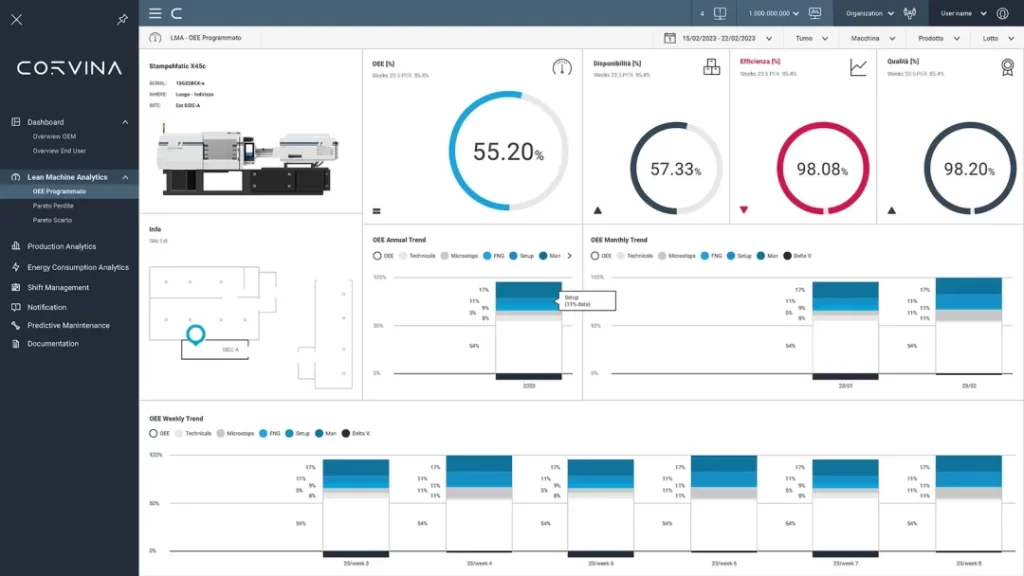

X-Series Mobile HMI More than just a handheld panel, it's a movableEdge Node. It can be paired with EXOR JMobile Software and CORVINA Cloud PlatformIt also realizes real-time connection between on-site data and the cloud system.

When service engineers conduct diagnosis on-site, the data can be synchronously uploaded to the cloud for real-time analysis by back-end experts, shortening the time to locate the problem.

Combined with the CORVINA platform dashboard, operators can view key indicators and alarms in real time on a handheld device, enabling mobile data visualization and status monitoring.

This combination enables equipment manufacturers to benefit from theHardware Sales"Turning toEquipment + ServiceThe "value model" of the company enhances business value-added and customer adhesion.

As a device built for the industrial field, thesecurityThis is the core concept of HONGKE X-Series HMI.

These details make the HONGKE X-Series HMI becomeIdeal for mobile operation and safety controlThe X-Series offers a wide range of features. At the same time, the X-Series offers 5", 7", and 10 Multiple screen sizes for flexible adaptation to different smart manufacturing scenarios.

虹科 AR 遠程醫療解決方案整合醫療級 AR 智慧眼鏡、AI 即時翻譯與遠程會診技術,支援跨語言醫療溝通、臨床教學與國際醫療合作,推動智慧醫療流程數位化升級。

虹科 PCAN 卡應用於隧道挖掘設備電控系統,支援 CAN / CANopen / J1939 通訊,協助工程設備實現穩定資料傳輸、精準控制與高可靠性運作,適用於鑿岩台車與隧道施工設備。

KnowBe4 為企業應對香港《關鍵基礎設施保護條例》提供了化繁為簡的解決方案。面對第 24 條與第 25 條的嚴格挑戰,它將難以量化的「人為風險」轉變為可追蹤的實戰數據,不僅彌補了傳統評估的盲點,更為年度審核提供了證明控制措施「有效運作」的鐵證。透過自動化報告與持續演練,企業能在大幅降低安全風險的同時,輕鬆滿足監管要求,實現從「被動合規」到「主動防禦」的關鍵轉型。