- Home

- Technical Products

Enterprise Cloud IT Solutions

Test Measurement

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Latest Articles

- About Us

EN

EN

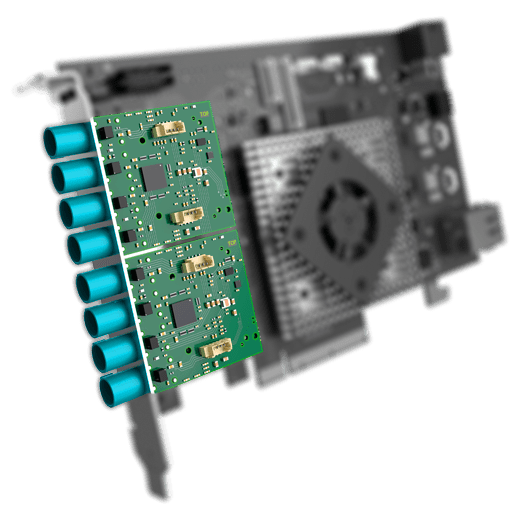

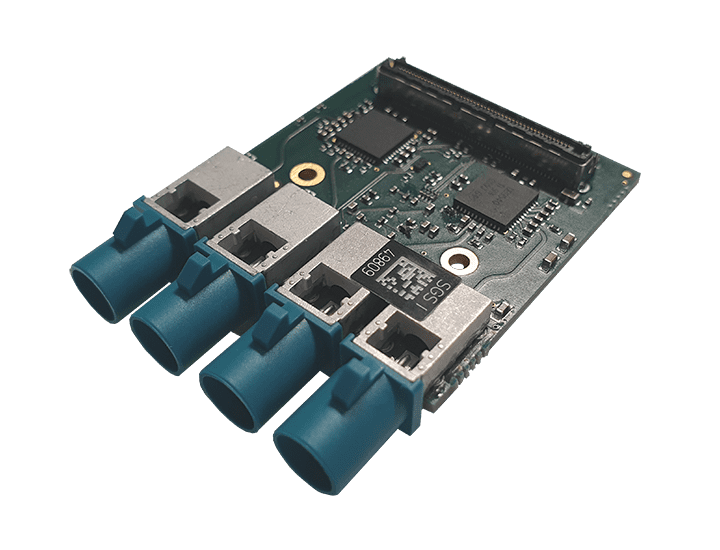

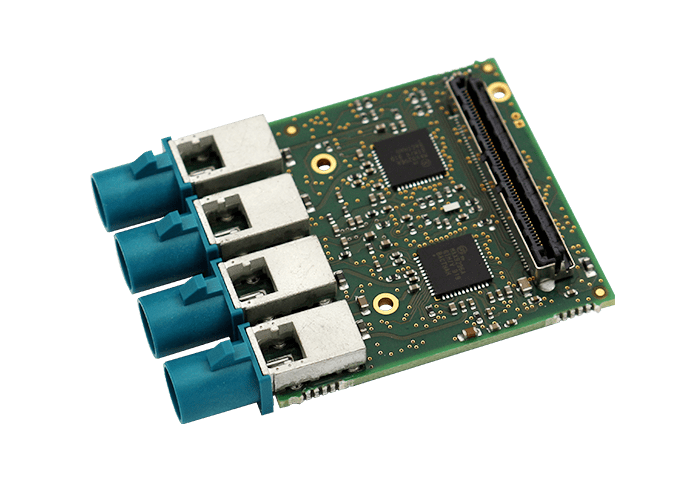

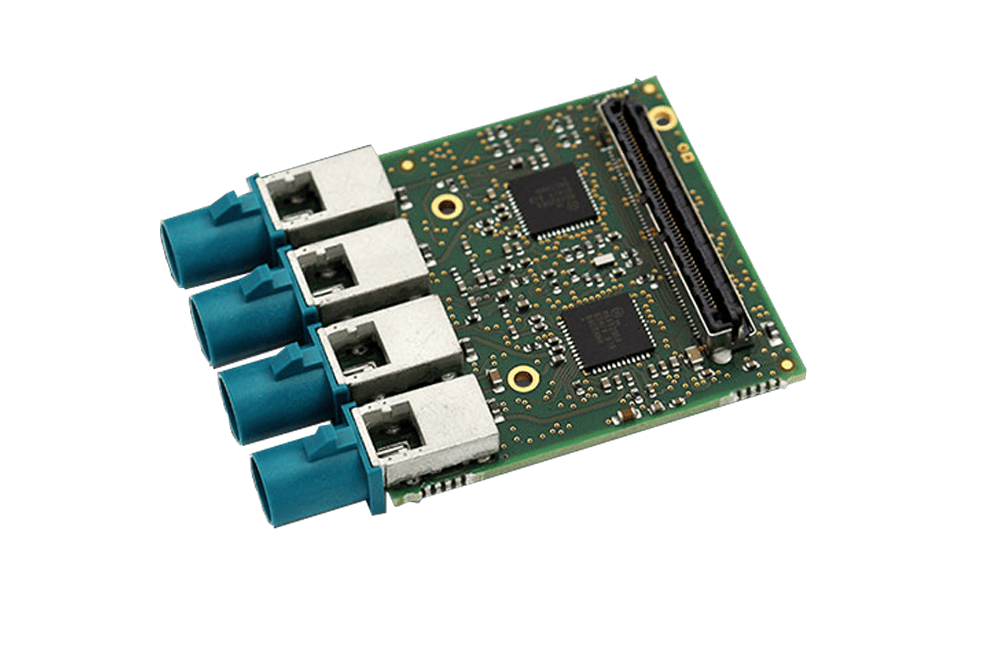

Modular Video Capture and Playback System proFRAME Camera Adapter

MaxicoM/TI Serial Deserialization Chip, Native Data and I2C Control

High-quality products from partner Solectrix System, mounted on corresponding proFRAME boards, available in a wide range of models and containing common (de)serializers to ensure compatibility

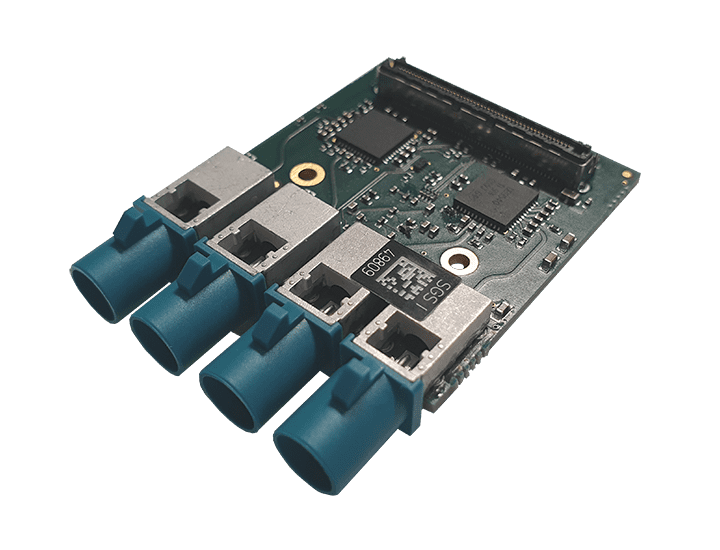

proFRAME 3.0 Camera Adapter

The camera adapter contains the camera interface and is mounted on the corresponding proFRAME system's base plate.

These adapters are available in a variety of models, including those for GMSL™ 1/2/3 and FPD-Link™ III/IV, as well as common (de)serializers (ADI Devices/Maxim, Texas Instruments) to ensure compatibility with a wide range of camera types. Additional camera adapters, e.g. for GigE Vision®, Camera Link®, etc., are available upon request.

Available Models

- GVIF3 Series:

camAD3 DUAL CXD4966/4967 - FPD-Link™ IV Series:

camAD3 DUAL FPD-Link IV (4xIN) - FPD-Link™ III Series:

camAD3 DUAL TI953/954

camAD3 DUAL TI954 - GMSL3™ Series:

camAD3 DUAL GMSL3 (4xIN)

camAD3 DUAL GMSL3 (2xIN, 2xOUT) - GMSL2™ Series:

camAD3 DUAL GMSL2 (4xIN)

camAD3 DUAL GMSL2 (2xIN 2xOUT) - GMSL1™ Series:

camAD3 DUAL MAX96705/96706

Available Models

camAD3 DUAL CXD4966/4967

- 2×SonyCXD4967 CSI-2® GVIF3 Serializer

- 2× SonyCXD4966CSI-2® GVIF3 Deserializer

- 2 camera outputs (Rosenberger FAKRA connectors), powered from ECU to camera via coaxial cable (PoC)

- 2 Camera Inputs (Rosenberger FAKRA Connector), 5 ~24 V Coaxial Cable Power Supply (PoC), External Power Supply Supporting PoC Voltage

- 4 CSI-2® interfaces to the substrate

- Lattice MachXO3™ management FPGAs

- Status LED

- Synchronized FSYNC triggers from the substrate

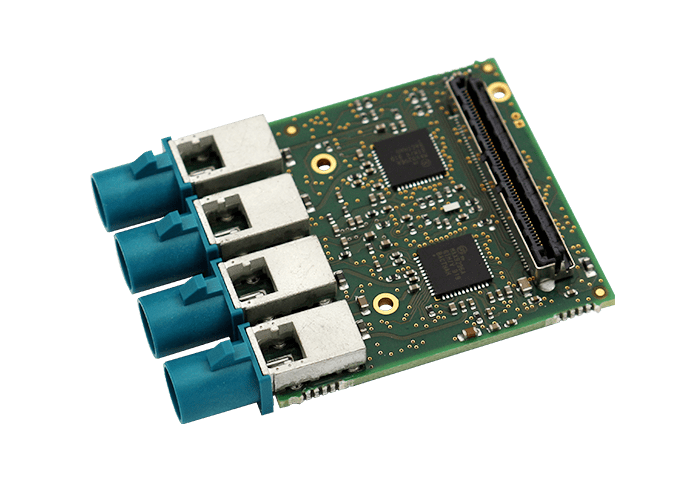

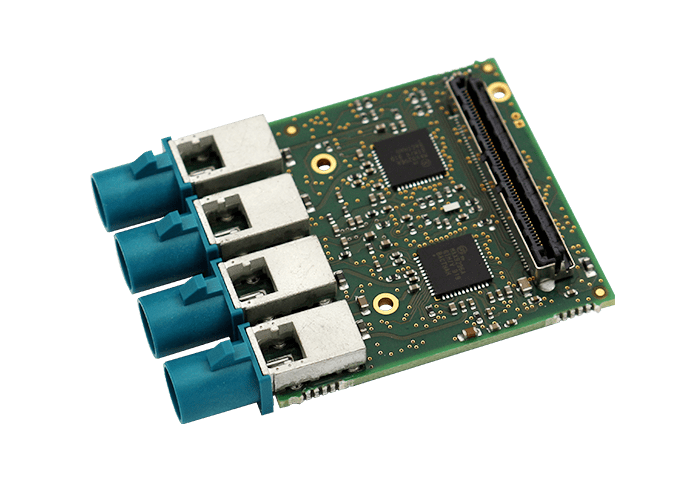

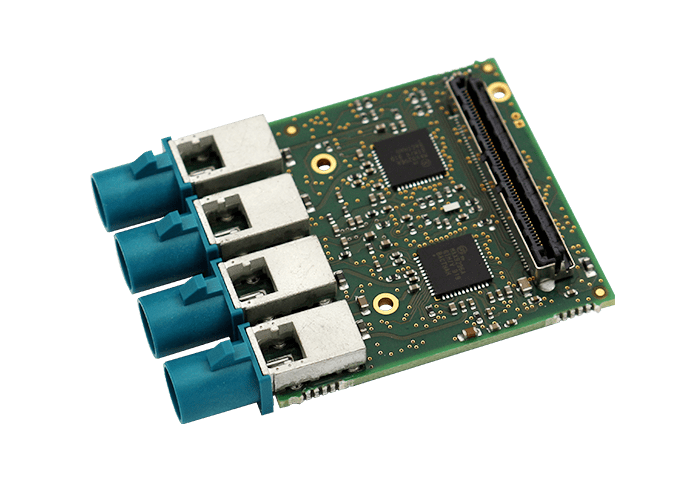

camAD3 DUAL FPD-Link IV (4xIN)

- 2× TI FPD-Link IV Deserializer

- 4 camera inputs (Rosenberger FAKRA connector)

- Lattice MachXO3™ management FPGAs

- Status LED

- Synchronized FSYNC triggers from the substrate

camAD3 DUAL TI953/954

- 2 x TI DS90UB953-Q1 CSI-2® FPD-Link™ III Dual Serializers

- 2 x TI DS90UB954-Q1 CSI-2® FPD-Link™ III Dual Deserializers

- 2 camera outputs (Rosenberger FAKRA connectors), powered from ECU to camera via coaxial cable (PoC)

- 2 Camera Inputs (Rosenberger FAKRA Connector), 5 ~24 V Coaxial Cable Power Supply (PoC), External Power Supply Supporting PoC Voltage

- 4 CSI-2® interfaces to the substrate

- Lattice MachXO3™ management FPGAs

- Status LED

- Synchronized FSYNC triggers from the substrate

camAD3 DUAL TI954

- 2 x TI DS90UB954-Q1 CSI-2® FPD-Link™ III Dual Deserializers

- 4 Camera Inputs (Rosenberger FAKRA Connector), 5 ~24 V Coaxial Cable Power Supply (PoC), External Power Supply Supporting PoC Voltage

- 2 CSI-2® interfaces to the substrate

- Lattice MachXO3™ management FPGAs

- Status LED

- Synchronized FSYNC triggers from the substrate

camAD3 DUAL GMSL3 (4 x IN)

- 2 x Maxim CSI-2® GMSL3 Dual Deserializers

- 4 x Camera Inputs (Rosenberger FAKRA Connector), 5 ~24 V Coaxial Cable Power Supply (PoC), External Power Supply Supporting PoC Voltage

- 4 CSI-2® interfaces to the substrate

- Lattice MachXO3™ management FPGAs

- Status LED

- Synchronized FSYNC triggers from the substrate

camAD3 DUAL GMSL3 (2 x IN, 2 x OUT)

- 2 x Maxim CSI-2® GMSL3 Serializers

- 2 x Maxim CSI-2® GMSL3 Dual Deserializers

- 2 camera outputs (Rosenberger FAKRA connectors), powered from ECU to camera via coaxial cable (PoC)

- 2 Camera Inputs (Rosenberger FAKRA Connector), 5 ~24 V Coaxial Cable Power Supply (PoC), External Power Supply Supporting PoC Voltage

- 4 CSI-2® interfaces to the substrate

- Lattice MachXO3™ management FPGAs

- Status LED

- Synchronized FSYNC triggers from the substrate

camAD3 DUAL GMSL2 (4 x IN)

- 2 x Maxim CSI-2® GMSL2 Dual Deserializers

- 4 Camera Inputs (Rosenberger FAKRA Connector), 5 ~24 V Coaxial Cable Power Supply (PoC), External Power Supply Supporting PoC Voltage

- 4 CSI-2® interfaces to the substrate

- Lattice MachXO3™ management FPGAs

- Status LED

- Synchronized FSYNC triggers from the substrate

camAD3 DUAL GMSL2 (4 x IN)

- 2 x Maxim MAX96705 CSI-2® GMSL1 Serializers

- 2× Maxim MAX96706 CSI-2® GMSL1 Deserializer

- 2 camera outputs (Rosenberger FAKRA connectors), powered from ECU to camera via coaxial cable (PoC)

- 2 Camera Inputs (Rosenberger FAKRA Connector), 5 ~24 V Coaxial Cable Power Supply (PoC), External Power Supply Supporting PoC Voltage

- 4 CSI-2® interfaces to the substrate

- Lattice MachXO3™ management FPGAs

- Status LED

- Synchronized FSYNC triggers from the substrate

Development, Diagnosis and Verification of Autonomous Driving / ADAS

The proFRAME system can be used to capture video data of the vehicle's surroundings.

real-time analysis of information on road conditions, vehicles and pedestrians.

and diagnose and verify the functionality and performance of the ADAS system.

Ensure system stability and accuracy.

Hardware-in-the-Loop (HiL System)

The proFRAME system can be used to capture and process data using sensors, actuators and other hardware.

Realize the simulation and modeling of the system.

It can capture HD video data in real time and synchronize it with other systems.

Provides more comprehensive data support for HiL testing.

Digital Microscope Technology

The system helps to realize high-definition video capture and playback of tiny objects.

Researchers in the fields of biology, medicine, materials science, etc. can use proFRAME

Observe microscopic structures, perform image analysis and measurements, and promote scientific research.

EOL Testing

The proFRAME system can be used to detect, acquire and analyze product quality data on the production line. Through video capture and playback, it is possible to visualize the product appearance, dimensions, manufacturing process, and other aspects of the product.

Testing and evaluating to ensure product compliance.

At the same time, it can help optimize production line efficiency and quality management.

Product Advantages

Modular system consisting of three parts with system accessories

The proFRAME series of modular video capture and playback systems consists of proFRAME boards, camera adapters, and supporting software, which can be paired with system accessories.

for capturing, playing back and processing raw video streams in a variety of applications, supporting common transmission technologies such as GMSL2™ and GMSL3™, FPD-Link™ III and IV (other technologies available upon request).

In the automotive field it is often used to verify ADAS systems or autonomous driving functions, but also in industrialized applications such as medical technology, digital microscopy and EOL testing.

Validate ADAS/AD embedded control units as intermediate media

In Hardware-in-the-Loop (HiL) testing of ADAS or AD functions, theThe corresponding ADAS/AD embedded control unit (ECU) provides the driving scene in the form of a video stream recorded during the test drive.

The key to verifying ADAS/AD functionality is the ability to accurately play back individual video frames with time stamps during the recording process. AndThe proFRAME system in HiL enables precise and synchronized playback of driving scenes for efficient verification.

The system provides a variety of different camera adapters that can be used to playback video streams using common serializers on the market (GMSL, FPD-Link), with playback based on single-image frame timestamp information or external triggering.

For HiL systems based on the software platforms ROS or ADTF, special integration templates in the form of ROS™ kits (ROS 2) and ADTF plug-ins (ADTF) are available.

Provide proFRAME SW API to connect with corresponding software platforms, thus realizing fast integration between proFRAME and HiL system.

High-performance system captures multiple camera data streams

ADAS systems such as traffic sign recognition, lane assist, parking assist, and autonomous driving (AD) functions require efficient and accurate collection of real-time data from vehicle sensors, especially video data from embedded cameras.

Validation of these features requires synchronized capture of video streams from each camera, with corresponding timestamps, and storage. These driving scenes are then played back into the verified ADAS/AD ECU during hardware-in-the-loop (HiL) testing.

proFRAME provides the perfect solution, which supports most common automotive cameras and can record up to 8 simultaneous 4K video streams (including sideband communication I2C), and has been successfully used for many years in a variety of data recorders.

The timestamps of the input data are processed with high precision in the hardware and can be synchronized with other recording devices via an external trigger cable. The camera can be supplied with programmable voltage via a coaxial cable (Power over Coax, PoC).

More Products

Door Vision Camera System

Clear all-weather imaging at night and in rain, fog and snow

VST VISDOM T Series

Modular adapters for collector cards

MaxicoM/TI Serial Deserialization Chip

Raw data and I2C control

Modular Capture Card Software

GPU-accelerated software libraries that enable video signal processing.

proFRAME SW/FW library

Modular Capture Card Accessories

Enabling the system to be used in more project scenarios

Thunderbolt3Box, LedAD3, SYNC

Frequently Asked Questions

What transmission technologies are supported by the proFRAEM system?

- MaxicoM: GMSL2™ & GMSL3™

- TI: FPD-Link™ III and IV

- Sony Semiconductor: GVIF

- (Other technologies available upon request)

How does the proFRAEM system synchronize the multiphase machines?

proFRAME supports synchronization of multiple cameras per board and synchronization of multiple boards. With the proFRAME SYNC adapter, synchronization signals for camera triggering can be obtained from an external triggering source and triggering signals can be generated in our proFRAME boards. These signals can be sent to the camera or to an external trigger receiver, and the adapter is available in both I/O and Dual-Input versions.

What are the common application areas?

As proFRAME has the ability to capture, playback and process raw video data streams from a variety of applications. The system is used in the automotive field to validate ADAS systems, hardware in-situ testing or autonomous driving functions. proFRAME is also used in industrialized applications in medical technology, in the field of digital microscopy (e.g. sinaSCOPE, a 3D digital microscopy platform) and in end-of-line testing.

How to quickly select a model for a project?

You can contact our staff and provide project information, our machine vision team will provide you with professional selection service.