- Home

- Technical Products

Enterprise Cloud IT Solutions

Test Measurement

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Latest Articles

- About Us

EN

EN

HONK B-Primis SC

Safety Controller

Save money by staying safe

Integrated CODESYS Programmable Security Solution

Product Advantage

Programmable

In this day and age, modern safety concepts are a must. The combination of macro safety relays and programmable safety technology gives machine and system manufacturers a competitive edge.

Reduce downtime

By providing a comprehensive overview of the process, safety relays ensure that errors are better located and diagnosed when they occur, which minimizes system downtime.

Product Composition

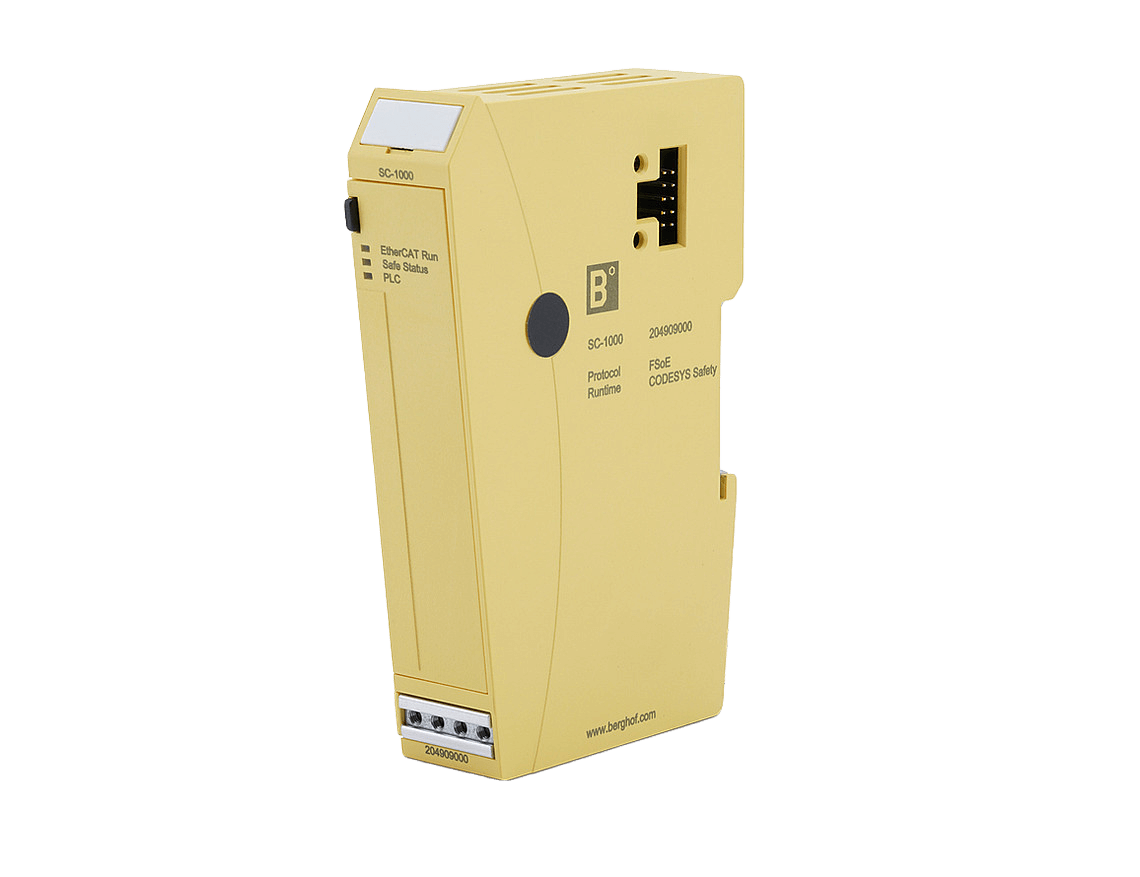

HONGKE SC-1000 Safety PLC/Safety Relay

Integrated, powerful and fully certified safety relays

- Certified PLCopen function blocks at basic and extended levels

- Certified Hardware

- Cross-communication between PLCs and safety PLCs

- Compatible with all standard products in the Berghof range.

- Expandable via modules and freely assignable within the system controller

- Direct connection to any FSoE slave (e.g. safety I/O, drive controller)

- Integration of security software into standard CODESYS

- Exchangeability of diagnostic, status and signaling information between levels.

- Security features: e.g. change tracking, secure signal flow, secure version control

- Online monitoring of safe and unsafe data

- SIL3 according to IEC 61508

- PLe in accordance with DIN EN ISO 13849

HONGKE SC-I/O Safety Module

Powerful, scalable and integrated

- Secure I/O with 4 digital inputs, 2 digital outputs

- Allows connection to all common security devices

- The signal is sent to the safety PLC via the internal EtherCAT bus system.

- Cross-communication between PLCs and safety PLCs

- Safe switching of actuators such as contactors, signal lights or drives via module outputs

- Comprehensive process overview

- Safety according to IEC 61508 SIL 3 and DIN EN ISO 13849-1 Ple.

- EtherCAT® Fail Safe (FSoE)

- Modular Scalability

Program Advantage

- programmable

- Modular safety features and modules

- Security Applications

- Solving Security Problems with an Expert Approach

The high degree of automation increasingly requires the flexible integration of individual safety functions, which makes theProgrammable Safety ControllerTruly state-of-the-art in future-oriented, competitive machines and systems. The innovative, integrated safety solutions from Avision include freely programmable CODESYS safety PLCs and safety I/O modules that meet the requirements of safety standards such as IEC 61508 SIL 3 and DIN EN ISO 13849-1 PLe.

The development environment provided by HONGKE SC Safety Relays allows the user to design the safety-related and functional parts of the application in an integrated manner. Although this requires a great deal of freedom, it meets the stringent requirements of safety applications without exception.

To enable project planners to accomplish their tasks in the best possible way, HOSCO SC adheres to the challenging PLCopen safety standard. The specifications defined for PLCopen safety are implemented consistently in both levels of programming rules. The basic level provides the user with certified function blocks, while the extended level offers almost unlimited possibilities in terms of safety-related functions.

HONGKE SC safety relays do not limit the range of functions and offer further safety programming verification mechanisms. Additional functions to protect all created safety applications are taken for granted. The number of available modules is limited only by the device memory.

These services offer the user almost unlimited possibilities. Common safety devices for the monitoring of operating elements, sensors or output signals pose no challenge, as do complex safety functions, depending on the requirements of the particular task.

CODESYS is considered one of the best and most popular manufacturer-independent programming standards. HOSCO SC offers the standard in its most comprehensive, unmodified form, thus providing numerous advantages to customers and end-users alike. The most common security concepts tend to focus on the hardware, but forget about the user's needs in terms of achieving a reasonable software integration.

The HONK SC safety package optimizes the interaction between hardware and software so that there is no boundary between "safe" and "non-safe" components for the user, which significantly simplifies programming and configuration. As a result, you can easily exchange diagnostic, status and signaling information between the two levels.

Being fully integrated in the CODESYS standard, the solution offers significant added value compared to other security solutions on the market.

Not leaving this important aspect to chance, Avision provides its users with training on all security-related topics to ensure the safe operation of the hardware and software. The basics are taught in the corresponding training modules:

-Using the CODESYS security plug-in

-Use a version of CODESYS that meets safety requirements

-Integrate security components into projects

-Security-related target system settings

-Creating security applications

-Introduces the most common safety modules

-Special use of safety components

-Put the controller in a safe state

-Data exchange between the secure CPU and the main CPU.

-Application Examples

-Q&A based on your individual needs