【虹科方案】AI+AR 重塑 PCB 質控流程|虹科 AR 智慧質檢解決方案

虹科結合 AR 智慧眼鏡與 AI 辨識技術,打造標準化 PCB 質檢工作流程,整合 MES、ERP、AOI 系統,降低漏檢率、提升良率,加速電子製造數位化升級。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The evolution of automotive electronics is accelerating, and the communication protocols between sensors and ECUs are becoming more and more diversified - the precise application of protocols such as PSI5, SPI, SENT, and DSI3 in power systems and vehicle safety modules has a direct impact on the reliability and performance of the entire vehicle. For leading automobile manufacturers and component suppliers, a complete test tool library covering multiple protocols is the core competitiveness to support parallel development of multiple product lines and quickly respond to technology iterations. The Seskion series of protocol simulators from HONGKE has become a practical choice for global leaders to strengthen their tool matrix with its in-depth adaptability to test scenarios.

As a globally renowned Tier 1 supplier, Bosch Automotive has officially introduced the "Tier 1" program in order to improve its protocol testing capabilities. SENT Sensor Protocol Simulation Test Solution by HONGKEIThis decision not only represents a high degree of recognition of the technology accumulated by Avision, but also benefits from the overall solution strength of Avision's full range of simulators spanning PSI5, DSI3, SENT, and SPI.

For automotive giants that invest huge amounts of R&D costs every year, the choice of tools is never about "whether they can be used or not", but "whether they can be matched with the strategy".

When the SENT protocol is widely used in pressure, acceleration and other critical sensors due to its simple frame structure and strong interference resistance, a set of test equipment that can accurately simulate the SENT signal and quickly locate communication faults has become an essential part of the R&D system. RequirementsThe

The nature of the supplemental SENT protocol tool is to fulfill three major R&D needs:

Covers multi-protocol parallel test scenariosTo avoid disruption of the R&D schedule due to lack of tools;

Reduce cross-team collaboration costs with standardized testing toolsThis allows for consistency and comparability of test data across different projects;

Relying on high-precision professional tools to identify communication risks in advanceThe company's products are designed to reduce potential rework costs during the mass production phase.

As Bosch Automotive said when they introduced the SENT simulator: "The comprehensive library of protocol tools allows us to stay ahead of the curve when it comes to getting new technologies off the ground."

The SENT simulator was favored by Bosch because of its "precise alignment" to the SENT test requirements.

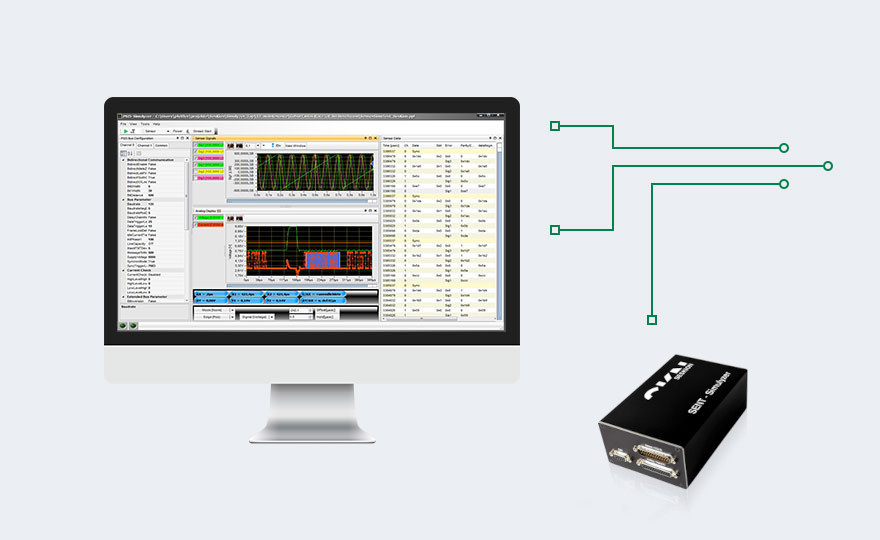

The SENT simulator is equipped with USB 2.0 and dedicated interfaces to ensure stable operation for long periods of time through external power supply. The device supports Windows 10/11 and .NET Framework 2.0, and also provides Linux APIs for seamless integration into an organization's existing test infrastructure.

3Ms/s high speed sampling rate: Capture SENT signal details with pinpoint accuracy

≥3 μs pumping time design: meets the stringent requirements of the protocol for timing accuracy

Full support for all SENT specification modes: From R&D, validation to pre-production conformance testing.

The optional Windows GUI visualization system provides a SENT-specific interface that can be configured:

Signal Definition

Data Format

Error Detection Rules

Trigger Conditions

Live Bus View" in the GUI helps engineers quickly locate communication anomalies; all data is automatically timestamped and supported. CSV (Excel) and .tdms (NI) Format export.

In addition, the equipment is built in:

ANSI-C API

LabVIEW 2016 (32/64bit) Function Library

It can be easily integrated into an automated test system to support highly customized requirements.

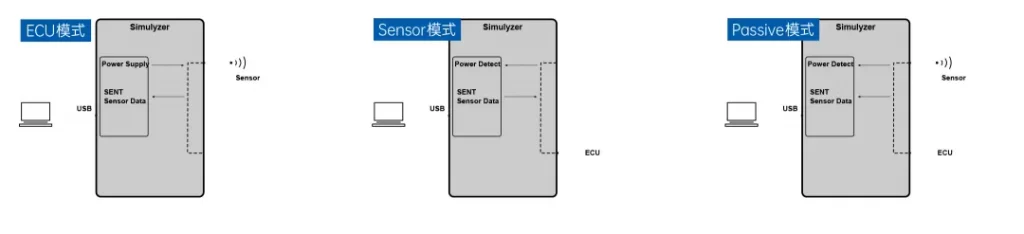

The SENT simulator supports three scene modes - creating a complete test closure:

ECU Mode: Simulate ECU commands to verify sensor reception logic.

Sensor Mode: Simulate signals of different operating conditions to check ECU resolution capability.

Spy mode: Real-time recording of bus traffic for protocol conformance analysis

This "one-machine-multiple-use" design effectively improves tool utilization and reduces the complexity of switching between multiple devices.

For enterprises focusing on R&D efficiency and technology precipitation, the tool itself is only the first step, and the "service capability" is the real key to determine the value.

Rainbow Technology's technical engineering team is available to companies:

Ensure that the equipment can be stabilized in the R&D and production chain from introduction to landing, so that enterprises can really reduce the cost of time and the risk of trial and error.

With a matrix of protocol simulator products covering PSI5, DSI3, SENT, SPI, Avision has become a technology partner of many leading companies in the field of automotive electronics.

HONGKE SENT simulators not only fill the gap in SENT test tools for automotive companies, but also provide solid support for sensor technology research and development as well as automotive electronics architecture upgrades with their high stability and flexible scalability.

虹科結合 AR 智慧眼鏡與 AI 辨識技術,打造標準化 PCB 質檢工作流程,整合 MES、ERP、AOI 系統,降低漏檢率、提升良率,加速電子製造數位化升級。

深入解析虹科 GNSS 模擬器如何支援無人機整機測試,涵蓋多星座 GNSS 仿真、RTK 公分級定位、抗干擾測試與多感測器融合驗證,助力高效、安全的 UAV 研發。

增材製造(PBF-LB/M)中的高精度過程監控與誤差檢測,虹科 iDS USB3 工業相機助力粉末層、再熔化層與動態飛濺監控,提升部件品質與研發效率,適用航空航天、醫療、汽車等行業。