- Home

- Technical Products

Enterprise Cloud IT Solutions

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Latest Articles

- About Us

EN

EN

OCT Imaging Systems and Solutions

- 1310nm center wavelength

- Up to 6mm deeper imaging depth

- Suitable for more biological/industrial testing scenarios

- Compact OCT host with integrated

- Includes spectrometer + reference arm + micro-computer

- Can be customized according to customer requirements

What is it? OCT ?

Technical Principles of OCT Imaging

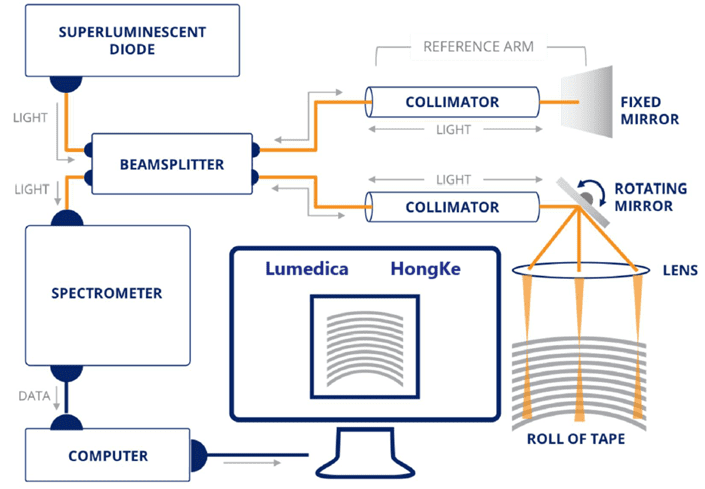

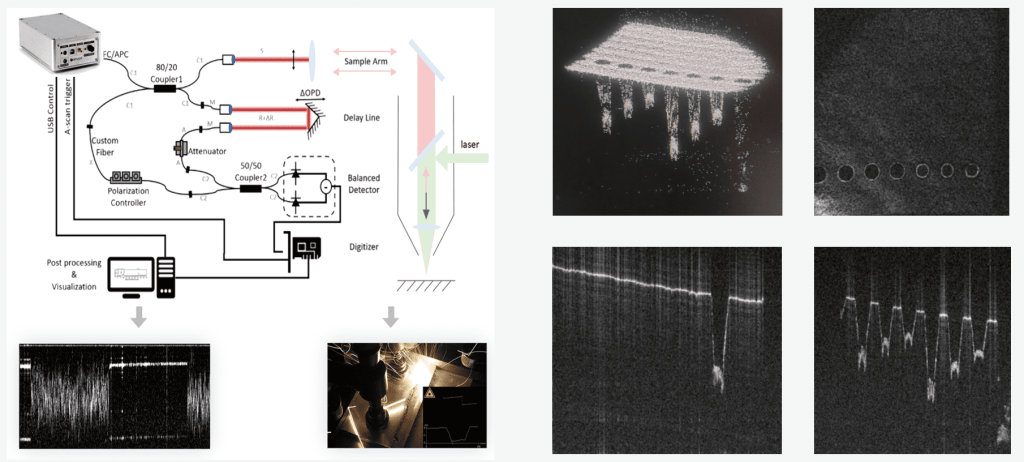

Light from the system light source, in the coupler is divided into two beams of the same frequency, the initial phase difference is constant parallel light, respectively, into the reference arm of the structure of the Michaelson interferometer and the sample arm, which the reference arm of the light by the reference mirror reflection and return to the subsequent optical path, the sample arm of the light to go through the sample layer of the scattering and reflection of the role of the light back to the optical path. If the optical range difference between the two returning beams is kept within a coherence length, interference can occur in the coupler. For time-domain OCT, the interference signals of different optical ranges can be obtained by moving the reference arm or changing the delay, while for frequency-domain OCT, single-point full-depth information can be obtained from a single scan by calculating the interference term through a fast Fourier transform.

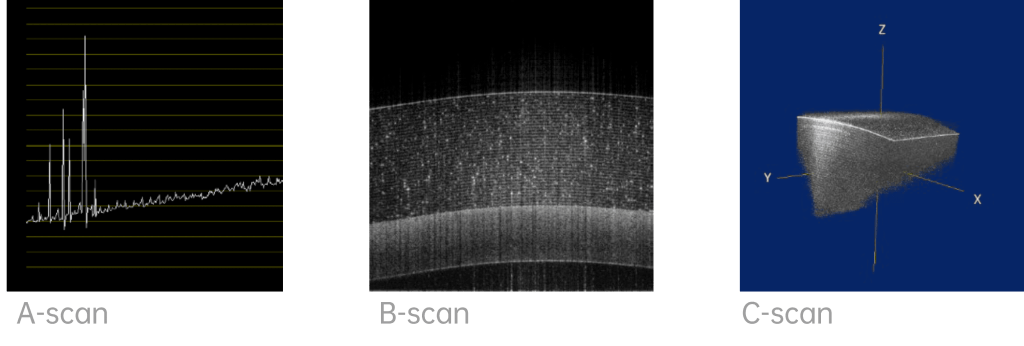

Imaging Example of Hongke OQLabscope Series OCT System

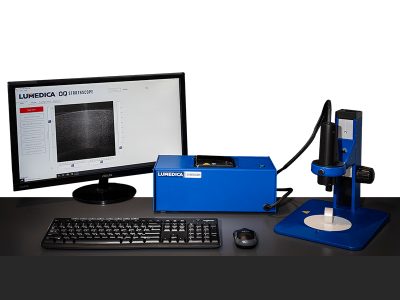

Hongke Partners with Lumedica to Provide Innovative OQLabscope Series of OCT Imaging SystemsWith its highly integrated, patented design, portable, and low-cost architecture, medical/biotech practitioners, innovative researchers, factory testers, and educators can easily take advantage of OCT's powerful imaging capabilities.

The OQ LabScope series generates 512 x 512 pixel images with 2um depth resolution, comparable to OCT systems costing three times as much as ours; fast image generation - up to 80kHz-A scanning speed for real-time 3D rendering; customized modules can be configured on demand for specific applications; optional workstation configurations - microprobe displacement stage, portable package configurations - handheld version, different light source wavelengths, scanning speeds, etc., supporting OEM customization. Handheld version, microscope, different light source wavelengths, scanning speeds, etc. OEM customization is supported.

Imaging Advantage Deciphering the Unknown

Low cost, high performance

Generates images of 512 x 512 pixels.

Depth resolution up to 2um

Equivalent performance to OCT systems costing three times as much as ours

Ultra-fast 3D imaging

Quickly generates images

Up to 80 kHz-A scanning speed

Real-time 3D rendering

Customizable Multi-Application

Configurable custom modules

Match your specific application

Fulfillment of your multiple needs

Workstation or Carrying Case

Workstation Configuration: Microminiature Stage

Carrying case configuration: Handheld version - microscope, different light source wavelengths, scanning speed, etc.

Support OEM customization

Wide range of applications with unlimited possibilities

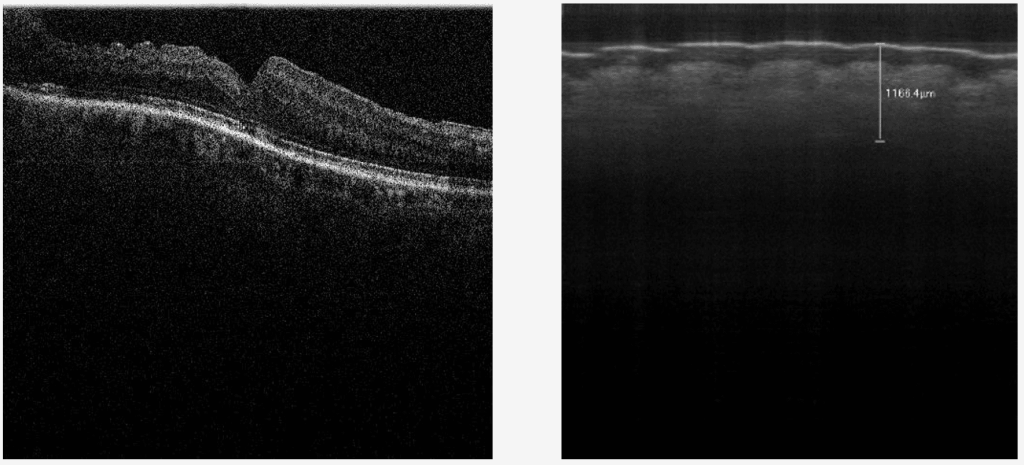

Ophthalmology/Skin Testing

Multilayered structure of the retina:OQ LabScope systems can be optionally equipped with specializedRetinal Imaging ModuleThe compact design offers the potential for a portable ophthalmic viewing device that can be easily combined with a fundus camera to provide multimodality testing.

Skin tissue stratification image:OQ StrataScope Maximum Imaging Depth Up to4.5mmIt can be widely used inIntradermal Stratigraphy 3D Characterization

Retina Human skin

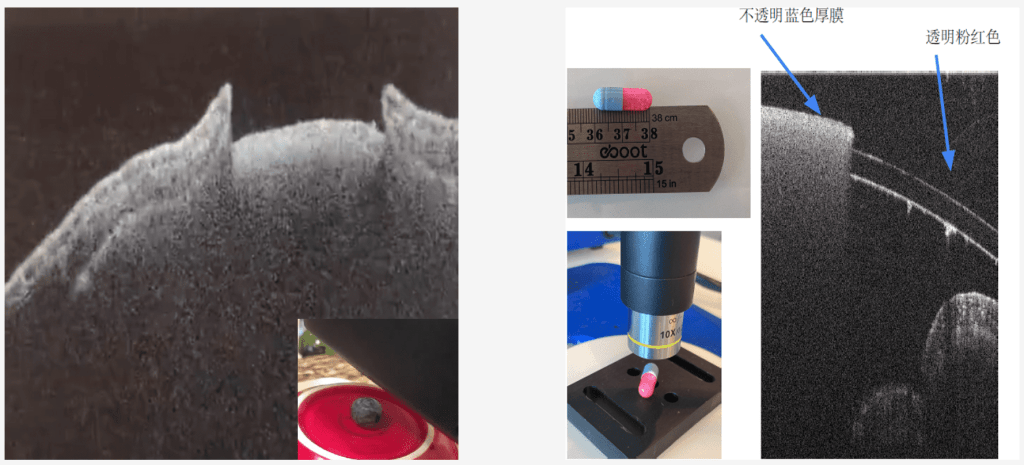

Blueberry capsule

Fruit/Drug Testing

Blueberry near epidermis:OQ LabScope 3.0 utilizes theHarmless near-infrared - short-wave infrared light sourcesThe scan can penetrate well into biological tissues, transparent/semitransparent materials, such as the epidermis of fruits at a depth of a few millimeters.

OCT image of the capsule:Reflective signals from the upper and lower surfaces of the capsule can be clearly identified and precisely analyzed.Thickness Measurement

The software also comes withAverage thickness measurement functionAutomatic measurement of capsule wall thickness.

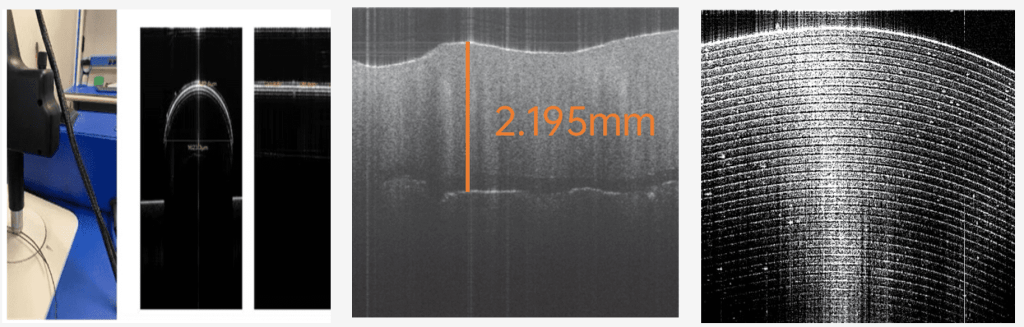

Non-destructive testing of industrial materials

Multi-reflective layers can penetrate the material:Typical OCT imaging samples - plastic polymer coatings, ceramics, various tapes (regular, insulated, insulated, cured, etc.)

OCT:Depth of penetration at the millimeter levelandMicron-level resolutionIt can clearly detect defects, bubbles, etc. within the object.

- Industrial production lineOK/NOOK Product Determination

- Easy access to optical interference informationDepth/Thickness/SizeMeasurement Data

Lead Layer Ceramics DefectsTape

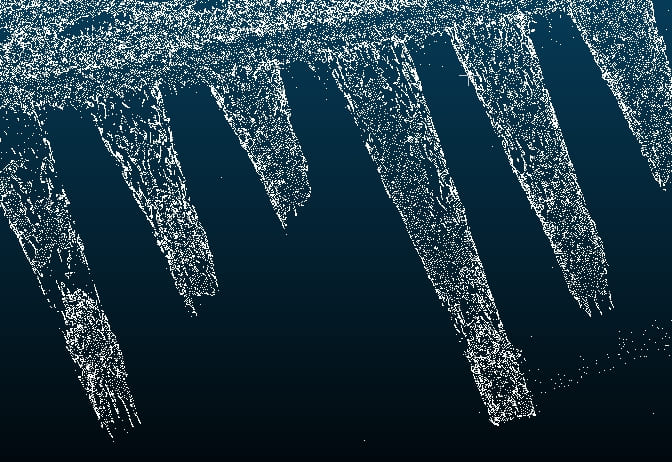

Inline Depth of Melt laser perforation

Laser Welding/Laser Punching

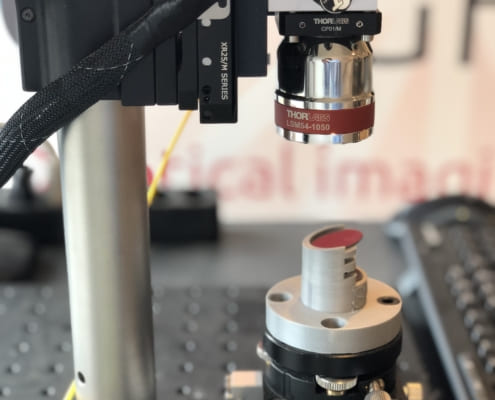

The OCT optical path can be easily combined with theCoaxial integration of processing optical paths

Laser Processing OCT Inline Depth of Melt Monitoring SystemBasic principle: OCT detecting light path and processing light path are coaxial, real-time monitoring of welding depth.

Laser drilling(OCT image of a workpiece (0.5mm hole diameter): Machining contour inspection over a wide area using a vibrating mirror.

Professional technical support from HONGKEI to help you succeed in your project.

As a provider specializing in machine vision and optoelectronic inspection solutions, Avision is also committed to providing you with a range of paid technical services related to this product, aiming to help you succeed in your project in the most cost-effective way. Please contact us if you need technical services related to this product!