【虹科動態】 虹科×長城汽車技術交流日回顧 – 智慧汽車、車載以太網、GNSS 測試全鏈路方案

2025年虹科攜手長城汽車於保定技術中心舉辦技術交流日,分享智慧汽車、車載以太網、GNSS測試、T-Box通信及aiSim仿真全鏈路方案,展示前沿技術應用與創新成果,助力汽車通信與智慧駕駛行業發展。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

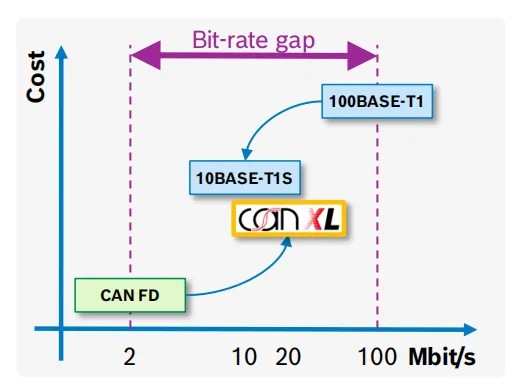

Today, with the rapid development of automotive intelligence and vehicle networking technologies, theIn-Vehicle Communication System It is facing unprecedented challenges. Although the traditional CAN CC and CAN FD buses have been in service for many years, they are still in the process of being replaced by the traditional CAN CC and CAN FD buses.Bandwidth, data throughput and real-time performanceIt has been difficult to meet the needs of the new generation of smart cars.

(indicates contrast) CAN XL Technology (Controller Area Network XL) It revolutionizes in-vehicle communication - not only is it perfectly suited for smart cars, but it also powersFlying carsandIntelligent RobotsThe development of the application.

As a next-generation CAN network protocol, theCAN XL While retaining the core advantages of the CAN series, it has been upgraded with a number of innovations. It follows the original physical layer design as far as possible, and only adopts the new frame format.High compatibility and low escalation costsIt also brings multiple breakthroughs in performance.

in terms of data transmission capacity.Data Field of CAN XL support sth. 1-2048 BytesThis is far more than the 8 Bytes of traditional CAN and the 64 Bytes of CAN FD, which greatly increases the capacity of a single transmission to meet the demand for transmission of large amounts of sensor data and high-resolution images in smart cars.

In terms of transmission rate, CAN XL'sArbitration zone rate ≤ 1Mbit/sbut (not)Data zone rate up to 1-20Mbit/sThe

Rates of up to 20 Mbit/s in a "CAN XL only" network and up to 8 Mbit/s in a "FD + XL hybrid" network.

CAN FD nodes automatically ignore CAN XL messages.The CAN XL node receives CAN XL and CAN FD messages at the same time, ensuring perfect compatibility and a smooth transition between the technologies.

In addition, CAN XL also supports the Virtual Bus (VLAN) concept from Ethernet with theEthernet TunnelingIt enables more flexible network hierarchical management and resource scheduling.

Double CRC verification (leading CRC and frame CRC) significantly improves data transmission accuracy and reliability, ensuring the integrity and stability of the frame header and the whole frame under high-speed transmission.

The CAN XL report (Frame) contains several key fields, each with a specific function, which together ensure efficient and accurate data transfer.

PID (Priority ID): Message ID with priority, 11-bit only, provides 2048 priorities (000h-7FFh) to ensure that high-priority data is transmitted first.

SDT (Service Data Unit Type): 8 bits to describe how CAN XL is compatible with other protocols (e.g. IEEE 802.3).

SEC (Simple/Extend Content)The 1 bit supports higher level functions such as bus safety and load balancing.

DLC (Data Length Code)The following table describes the length of the data area: 11 bits, which defines the data area length range of 1-2048 Bytes.

PCRC (Preamble CRC): 13 bits for header error detection to improve reliability.

VCID (Virtual CAN Network ID)The 8 bits, similar to a VLAN, can distribute messages to a virtual CAN network for enhanced QoS and traffic control.

AF (Acceptance Field): 32 bits for filtering and reception management, ensuring that the node processes only the necessary data.

DATA (Data Field): 1-2048 Bytes for carrying the actual data load.

FCRC (Frame CRC)The 32 bits, whole-frame message validation ensures data integrity.

CAN FD Light As a lightweight extension of CAN FD, it utilizes a master-slave structure (similar to LIN), supports 11-bit ID (no frame expansion), and up to 64 Bytes of data transfer.

Its application covers the scene:

Automotive lighting (headlights, taillights, ambient lighting)

Battery Management System (BMS Submodule)

Actuators / Sensors (HVAC, Ultrasonic, Wiper Control, etc.)

White Home Appliances and Low-Cost Control Scenes

CAN FD Light toLow Cost + High StabilityThe advantages make it an ideal choice for low and medium speed communication applications.

Have you encountered these two difficulties when you first contacted CAN XL?

❌ No adapted docking device

❌ Cannot find professional software to analyze the frame data.

HongKe PCAN XL Starter Bundle (HongKe PCAN XL Starter Bundle) Designed to address these entry pain points - a complete toolset for "hardware connectivity + software analysis" to help newcomers get started with CAN XL.

HongKe PCAN XL Kit of the core configuration is included:

USB to CAN XL interface: Stable connection, plug-and-play;

PCAN-Explorer 7 Professional Analysis Software (Sneak Peek Version): Efficiently analyzes frame data and visually displays communication status;

PCAN-Basic Programming Interface: catering to both beginner and advanced development needs.

Considering that CAN XL communication requires at least two nodes, HongKe offers Single Interface Version / Dual Interface Version Two sets:

A menu interface version is available for users who already have a CAN XL device;

For those who don't have existing equipment, a dual interface version is available to create a complete communication link right out of the box.

From development testing to real-world applications, the HongKe PCAN XL suite makes it easy for companies and engineers to accomplishTechnology upgrade from CAN FD to CAN XLIn addition, it also realizes a higher speed and more flexible in-vehicle communication architecture.

2025年虹科攜手長城汽車於保定技術中心舉辦技術交流日,分享智慧汽車、車載以太網、GNSS測試、T-Box通信及aiSim仿真全鏈路方案,展示前沿技術應用與創新成果,助力汽車通信與智慧駕駛行業發展。

虹科 GNSS 模擬器提供消費電子、導航晶片與定位終端測試解決方案,精準模擬全球衛星導航信號(GPS、GLONASS、Galileo、北斗),提升定位精度、時間同步與數據處理效率,保障產品質量並縮短研發周期。

虹科基於醫療級 AR 智慧眼鏡的遠端醫療解決方案,成功實現中國首例 AR 遠端顱骨修復手術指導。憑藉 ISO 無塵室與 EMI 雙重醫療認證,協助推動分級診療,全面提升手術安全性與醫療協作效率。