【虹科方案】從被動防禦到主動預防:用 KnowBe4 輕鬆應對關鍵基礎設施條例風險評估與審核

KnowBe4 為企業應對香港《關鍵基礎設施保護條例》提供了化繁為簡的解決方案。面對第 24 條與第 25 條的嚴格挑戰,它將難以量化的「人為風險」轉變為可追蹤的實戰數據,不僅彌補了傳統評估的盲點,更為年度審核提供了證明控制措施「有效運作」的鐵證。透過自動化報告與持續演練,企業能在大幅降低安全風險的同時,輕鬆滿足監管要求,實現從「被動合規」到「主動防禦」的關鍵轉型。

Description.

Under the wave of Industry 4.0, technological innovation is comprehensively promoting equipment to intelligent and efficient. Among themCAN bus technologyBy virtue of itsLow cost, high reliability, strong electromagnetic interference resistanceWith the advantages of the technology, it has been widely used in the engineering machinery and other industrial scenes, and has become one of the core technologies for efficient communication among equipments.

As a technology service provider specializing in the field of industrial communications.HONGKE PCAN Series ProductsPCAN has been widely used in the field of construction machinery, realizing real-time data exchange and precise control of equipment. In the future intelligent construction sites and intelligent manufacturing scenarios, PCAN is not only a bridge for stable communication, but also a means of realizingData-Driven Decision Making and Remote Collaborative ControlThe key to this is the key sharpener.

CAN bus, known as Controller Area Network, is one of the most widely used field buses in the world. It is a kind of CAN bus specially designed forDecentralized and real-time controlThe CAN bus is a serial communication network designed by BOSCH in Germany in the early 1980s for the exchange of data between the many electronic control units (ECUs) in modern automobiles. As technology continues to evolve, CAN bus technology has matured and become internationally standardized, with applications expanding from automotive to industrial control and sensors.

In traditional control systems for construction machinery, the presence of a large number of sensors, instruments and control components has led to an increase in the number and type of wires and a rise in the number of nodes. This not only increases the complexity of electrical design, but also makes wiring difficult, decreases reliability, and extends troubleshooting time.

In response to these challenges, CAN bus technology has been utilized with itsLow cost, simplified cabling, high reliability, high speed transmission capability and high flexibility.In particular, theExcellent resistance to electromagnetic interferenceThe CAN bus has become the communication solution of choice for the construction machinery industry. Through the application of CAN bus, the intelligence level of construction machinery can be greatly improved, effectively meeting the higher requirements for equipment performance and reliability in the new era.

HONGKE PCAN series devices can connect CAN network messages to computers through various interfaces such as USB, PCI, PCIe and miniPCIe to realize the CAN messages.Monitoring, sending, storing and filteringFunctionality. The series supports CAN 2.0A and 2.0B protocols and CAN bus connection via D-Sub 9 pins, with up to 500V electrical isolationIt is ideal for construction machinery and other demanding industries.

At present, CAN bus technology has been widely used in the field of construction machinery, includingRollers, Excavators, Mining Forklifts, Paversand many other types of equipment, as well as construction machinery equipmentFirmware Download and Upgrade SceneThe technology can be used in a variety of ways. The technology can be used inNo change to the original system operation mechanismto optimize the deficiencies in the control methods of traditional engineering machinery under the premise of theEnhance the performance, safety and stability of your equipment.The

The control system of the roller includes the bus communication programming, controller module and display module. Combined with the CAN bus technology, the data communication can be realized in the serial network, and the whole system can be designed as an upper and lower machine position structure.Avision PCAN-USB provides a free program development interface, PCAN-Basic API.It supports secondary development and system integration.

The PCAN-USB plays a key role in the hydraulic control system of the excavator, collecting real-time driving operation data through the CAN bus and realizing online monitoring of gear position, power and engine status, which further enhances the operation efficiency.Accuracy and SecurityThe

In automated unmanned forklifts, CAN bus technology combined with Avision's PCAN-USB enables efficient data acquisition, analysis and processing of sensors and control systems to support precise control of the forklift and movement.Effectively reduces the risk of manual intervention under adverse working conditions.The

The application of CAN bus technology on the paver realizes the centralized monitoring of equipment operation status. Hongke PCAN-USB with PCAN-View and PCAN-Explorer software, which not only monitors CAN reports, but also graphically displays the signals through a graphic panel plug-in.Dramatically improves the intuitiveness and ease of operation of the surveillance.The

Many machine controllers have CAN bus interfaces in the field to connect to host computer software to support controller firmware programming.Avision PCAN-USB is compatible with a wide range of third-party software.For example, the underlying software for the EPEC controller is flashed through CANmoon software, and the control logic program is written through Codesys software, making the process flexible and efficient.

Supports multiple CAN interfaces: Cover USB, PCI, PCIe, miniPCIe and other connection methods

Optical isolation design: Photo-Isolated version can withstand up to 500V High VoltageTo ensure system stability

Multi-Channel Support: Single Module Support 1 to 6 high speed CAN channels(in accordance with ISO 11898-2)

Standard Bus Connection: Connects to the CAN bus via connection cable and D-Sub 9 connector (CiA®106 compliant)

Flexible Baud Rate Range: Supports baud rate from 5 kbit/s to 1 Mbit/s

Strong protocol compatibility: Fully compliant with CAN 2.0A (11-bit ID) and CAN 2.0B (29-bit ID) specifications

Channel isolation protection: each CAN channel is isolated from each other, some models offer galvanic isolation

Free Software Support: Provide host computer software PCAN-View and secondary development kits PCAN-Basic

Cross-Language Development InterfacePCAN-Basic API supports C++, C#, VB, C++/CLR, Delphi, .

Wide temperature design: Supports extended operating temperature range -40 ~ 85°C (-40 ~ 185°F)

Conclusion:

Hongke PCAN-USB is not only a key bridge for the intelligentization of construction machinery, but also a gas pedal for the technological upgrading and digital transformation of the industry. With the continuous evolution of technology, Hongke PCAN-USB will continue to play an important role in the field of construction machinery, and provide more efficient and smarter solutions for customers around the world.

📩 For more information, please contact our professional team, we are happy to provide you with technical support and application consulting.

KnowBe4 為企業應對香港《關鍵基礎設施保護條例》提供了化繁為簡的解決方案。面對第 24 條與第 25 條的嚴格挑戰,它將難以量化的「人為風險」轉變為可追蹤的實戰數據,不僅彌補了傳統評估的盲點,更為年度審核提供了證明控制措施「有效運作」的鐵證。透過自動化報告與持續演練,企業能在大幅降低安全風險的同時,輕鬆滿足監管要求,實現從「被動合規」到「主動防禦」的關鍵轉型。

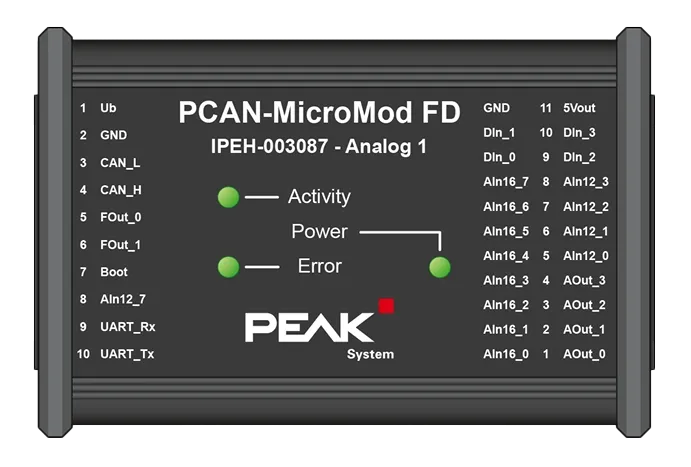

安鵬精密於實際 NVH 路測中,透過虹科 PCAN-MicroMod FD,將車輛 CAN / CAN FD 訊號即時轉換為類比電壓,無需二次開發即可完成訊號同步,低成本整合既有 NVH 資料採集系統。

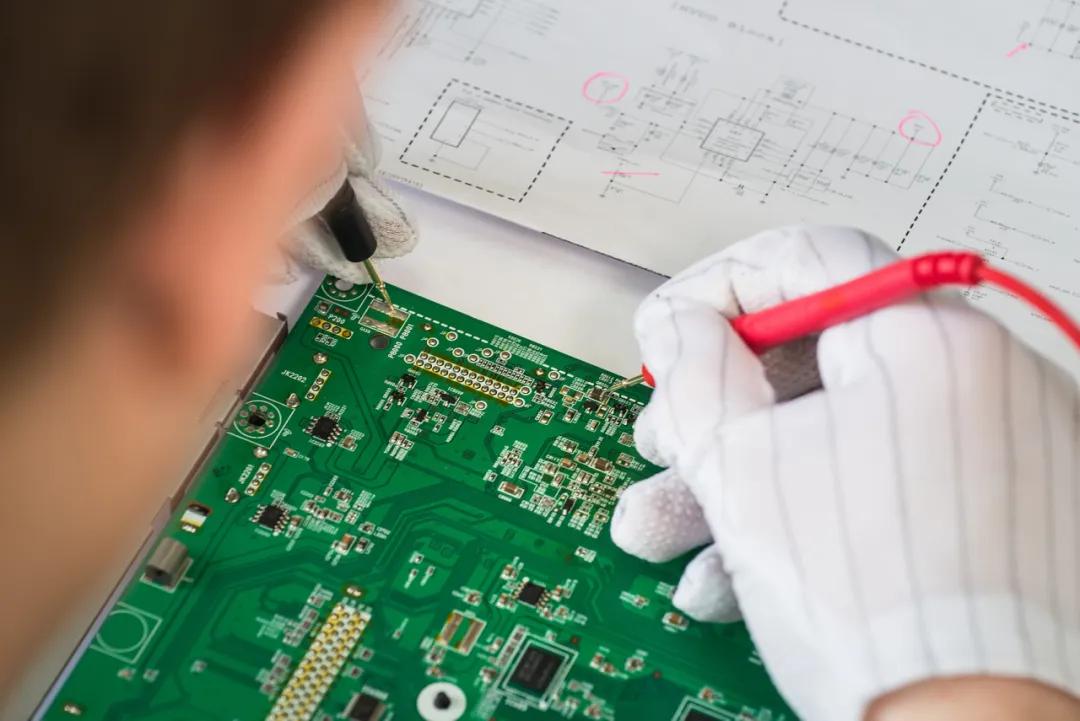

虹科結合 AR 智慧眼鏡與 AI 辨識技術,打造標準化 PCB 質檢工作流程,整合 MES、ERP、AOI 系統,降低漏檢率、提升良率,加速電子製造數位化升級。