【虹科方案】 SimData 高保真虛擬數據集 – 基於 aiSim 的自動駕駛多傳感器感知數據方案

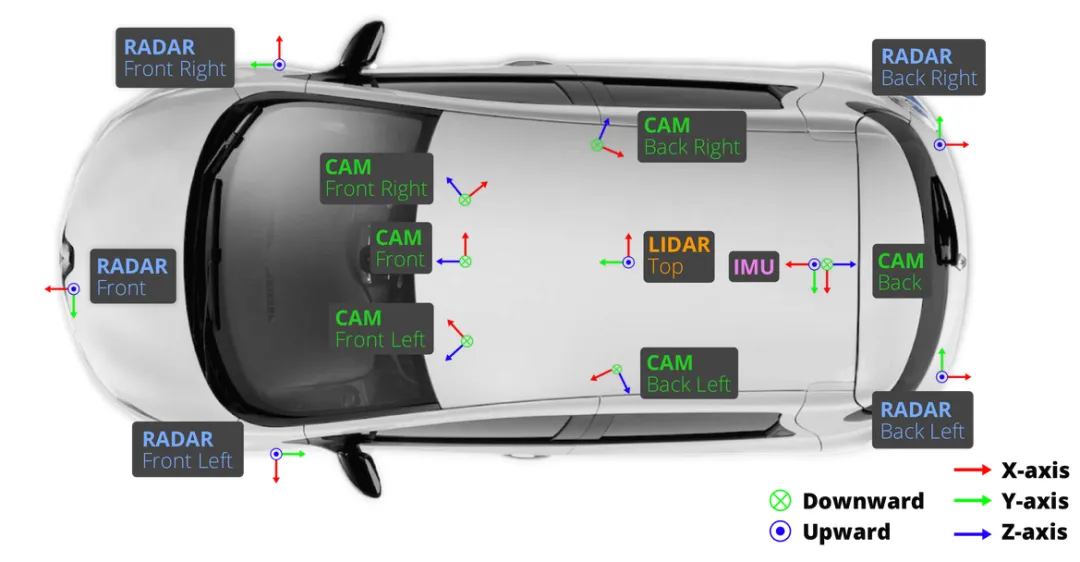

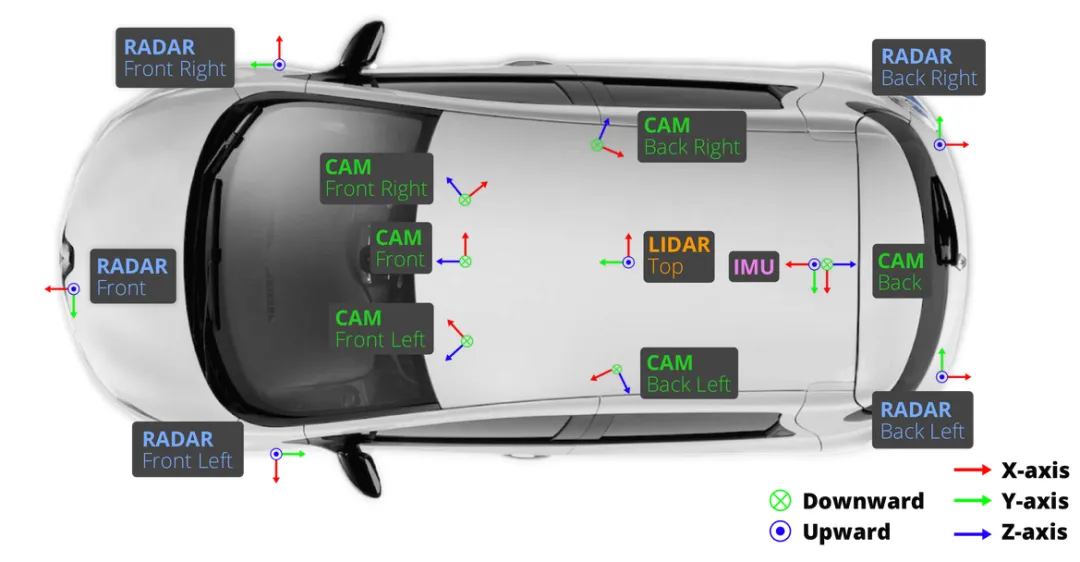

SimData 為基於 aiSim 仿真平台生成的高保真虛擬感知數據集,支援 Camera、LiDAR、Radar、IMU 多傳感器同步數據,結構完全對齊 nuScenes,可直接使用 nuscenes-devkit 進行解析與模型訓練。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

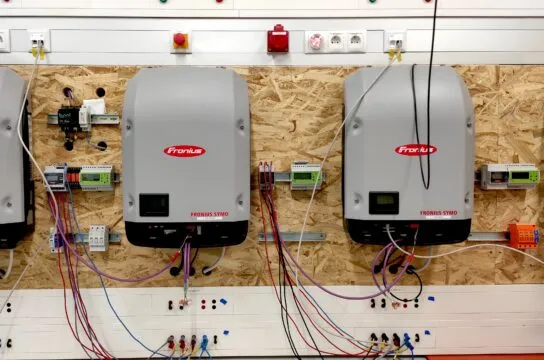

In recent years, the number of new energy vehicles has continued to grow at a steady rate. Annual growth rate of 30%+Demand for charging is surging in tandem with the rise in demand. With the rapid rollout of large-scale charging infrastructure, the "How to ensure the safe and stable operation of charging stations"andHow to Reduce Operation and Maintenance Costs and Increase EfficiencyThe "charging" has become a core issue for charging operators.

A new centralized charging station, configured by a regional operator:

Such a high-density, high-power configuration allows the station to be Power Quality, Protection Response Speed, Remote Visualization Management We are facing a great challenge in this regard.

In actual operation, the centralized charging station has revealed a number of technical bottlenecks:

The above conditions can interfere with other equipment in the station and cause stability risks in the communication and power modules.

The worst case scenario can lead to power module damage, insulation breakdown, and possibly even toVehicle BatteryThis has led to significant safety hazards.

In order to solve the above problems, the project owner needs a set ofFast response, accurate protection, remote managementThe "Intelligent Electrical Protection Program.

In view of the high power characteristics and operation and maintenance requirements of centralized charging stations, the project team finally selected HONGKE TELE NA003 Grid and System Protection RelayIt also provides a layered deployment and parameter optimization to realize the protection strategy and visual monitoring of the whole link.

exist 10 kV feeder main cabinetand distribution boxes in each district NA003 → Realization Total → Divisions → Returns Full Chain Protection.

Monitor voltage 0-560 V, frequency 40-65 Hz, RoCoF, phase deviation, and support forCustomized Trip Threshold,The delayed start time can be set.

NA003 Ownership Millisecond cutoff capabilityIt is very suitable for fast charging pile high transient scenarios, can quickly isolate the fault to avoid collateral damage.

With this setup, HONGKE TELE NA003 not only provides "millisecond fast protection", but also incorporates the protection data of the whole station. Remote Maintenance SystemIn addition, the management of charging stations has become more intelligent and transparent.

Hongke TELE NA003-M64 Designed for distributed power grid protection with:

In the event of a power supply interruption or energy supplier failure, it can be used in Milliseconds Cut the circuit to ensure the safety of small power generating equipment and personnel.

Key Features:

After three months of actual operation, HONGKE TELE NA003 has brought significant results:

After the centralized charging station has been in operation for three months, the effect of HONGKE's TELE NA003 deployment is very obvious. First of all, the overall downtime has decreased by more than 40% compared to the initial period of operation, and the overall availability of charging stations has increased from about 95% to nearly 99%, which has greatly enhanced the service capacity and operational stability of the stations. Secondly, during high load periods such as morning and evening peaks, the service capacity of a single station has been increased by 20 to 30 units, enabling the charging station to maintain a more stable power supply quality and operational efficiency in the face of rapid changes in load.

At the same time, since NA003 supports Modbus real-time data upload and seamless access to SCADA system, operation and maintenance personnel can remotely locate abnormalities and significantly shorten the troubleshooting time, which reduces the frequency of inspection by about 30%, significantly increases the number of stations managed by a single person, and improves the overall efficiency of operation and maintenance.

In addition, the project team estimated that the charging stations could reduce maintenance and downtime losses by about $400,000 to $500,000 per year, mainly due to the reduction in the number of equipment breakdowns, downtime and labor costs. Overall, HONGKE TELE NA003 not only improves operational safety, but also brings quantifiable economic benefits to the stations.

SimData 為基於 aiSim 仿真平台生成的高保真虛擬感知數據集,支援 Camera、LiDAR、Radar、IMU 多傳感器同步數據,結構完全對齊 nuScenes,可直接使用 nuscenes-devkit 進行解析與模型訓練。

虹科 AR 遠程醫療解決方案整合醫療級 AR 智慧眼鏡、AI 即時翻譯與遠程會診技術,支援跨語言醫療溝通、臨床教學與國際醫療合作,推動智慧醫療流程數位化升級。

虹科 PCAN 卡應用於隧道挖掘設備電控系統,支援 CAN / CANopen / J1939 通訊,協助工程設備實現穩定資料傳輸、精準控制與高可靠性運作,適用於鑿岩台車與隧道施工設備。