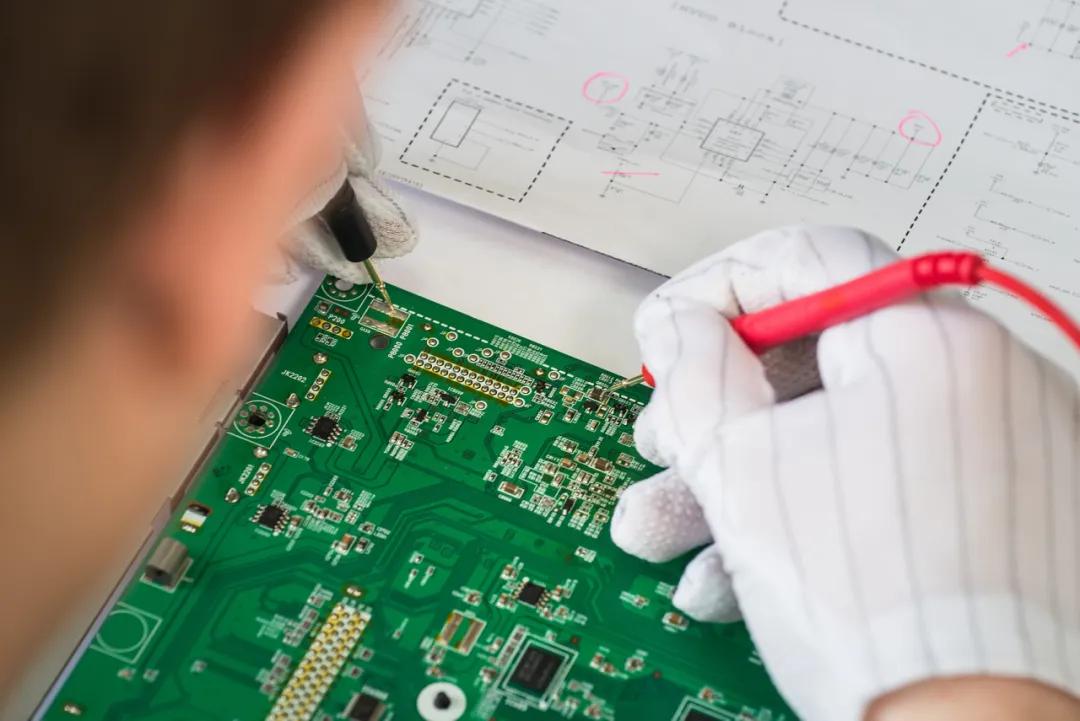

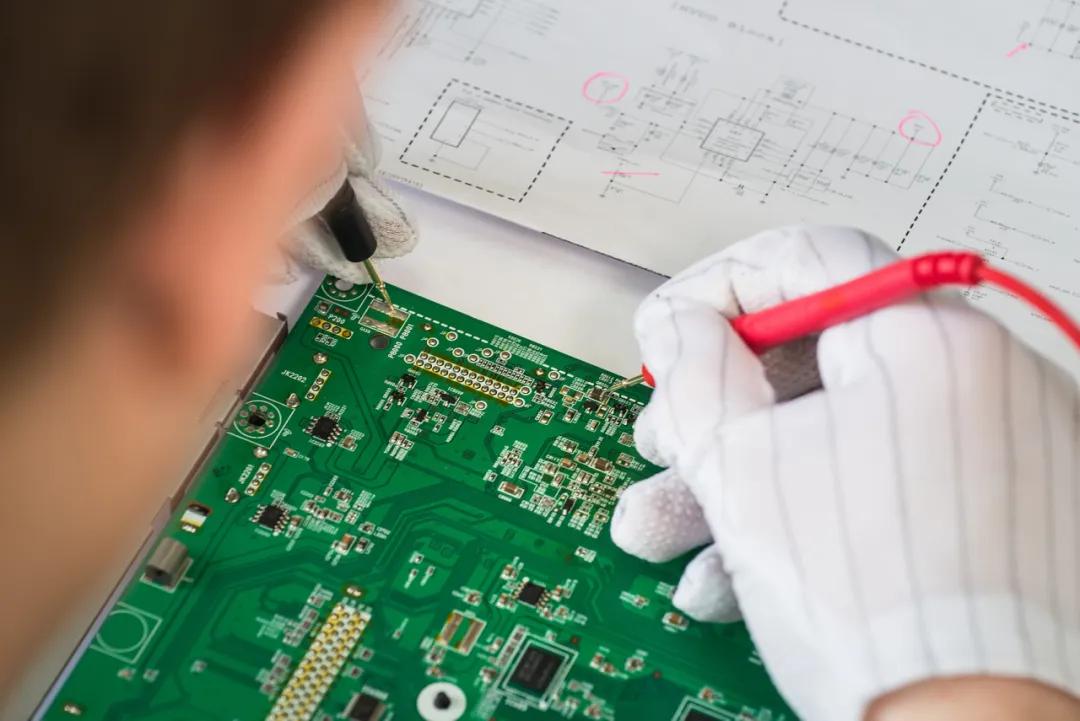

【虹科方案】AI+AR 重塑 PCB 質控流程|虹科 AR 智慧質檢解決方案

虹科結合 AR 智慧眼鏡與 AI 辨識技術,打造標準化 PCB 質檢工作流程,整合 MES、ERP、AOI 系統,降低漏檢率、提升良率,加速電子製造數位化升級。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

With rising energy costs and increasingly stringent energy-saving and emission-reduction policies, building energy optimization has become a key aspect of digital transformation for enterprises. In the face of energy wastage and equipment inefficiency that are invisible to the naked eye, how can business managers accurately identify and tap into the "invisible energy-saving potential"? The answer is exactly:Energy SCADA System (Energy SCADA)The

The core role of SCADA in energy management is to digitize the energy consumption of buildings. Real-time monitoring, analysis and optimizationIt can help enterprises to continuously improve energy efficiency and form a closed-loop energy efficiency improvement mechanism. It can help enterprises to continuously improve energy efficiency, form a closed-loop energy efficiency improvement mechanism, and truly implement smart energy saving.

Through the SCADA platform, the building's Electrical, HVAC, lighting, etc. systems The system can monitor and control all aspects of energy consumption, and provide automatic alerts and intelligent adjustments in the event of abnormal fluctuations or energy wastage. This data-driven energy management model not only effectively reduces costs, but also helps companies meet various energy-saving regulations (e.g., France's Tertiary Energy Efficiency Decree, China's "Double Carbon" standard, etc.).

BMS is the core infrastructure of energy SCADA, which collects building operation data through a network of distributed sensors and actuators, and regulates HVAC, lighting and other equipment in an automated manner.

A well-established BMS typically includes:

Environmental SensorsTemperature, CO₂, brightness, etc.

Enforcer: Valves, Thermostats, Lighting Control Modules

controllers: parsing data, triggering control logic

Communication Agreement: BACnet, Modbus, etc.

HMI Human Machine Interface: Visual monitoring and parameter setting

According to Energies Dev, intelligent BMS control can reduce energy consumption by as much as 30%This is especially true for high energy consumption scenarios such as HVAC.

In the SCADA architecture, sensors and smart metering devices are the core of the "sensing layer" of energy monitoring.

High-frequency energy-consuming data collection and remote transmission can be realized through multiple types of sensors (power, heat, motion, etc.) and IoT communication technologies (LoRaWAN, Sigfox).

Focused control is required during deployment:

Accurate mapping of key energy consumption points

Sensors near major energy-consuming equipment to improve representativeness

Real-time data upload to SCADA to support predictive maintenance

This approach significantly reduces the risk of downtime and equipment failures, and enhances the reliability of energy management.

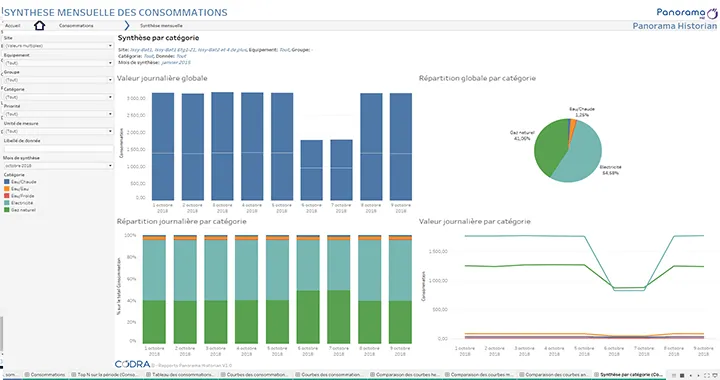

Modern Energy SCADA platform integration:

Real-time monitoring

Trend Analysis

Data Modeling

Visualization

Helps managers to quickly pinpoint building energy consumption problems and develop improvement strategies.

An ideal SCADA system should have:

Real-time Alarms: Instant alerts for energy abnormalities

Multi-source data analysis: Electricity, gas and water analysis

Highly interoperable: Seamless integration with BMS/building equipment

Compliance Support: Compliance with EU BACS regulations, etc.

HOSCO Panorama SCADA Platform Adopting modular architecture and open communication interface, it can flexibly integrate architectural and industrial equipments, and open up the complete chain from data collection, visual display to energy consumption analysis, thus truly realizing energy transparency.

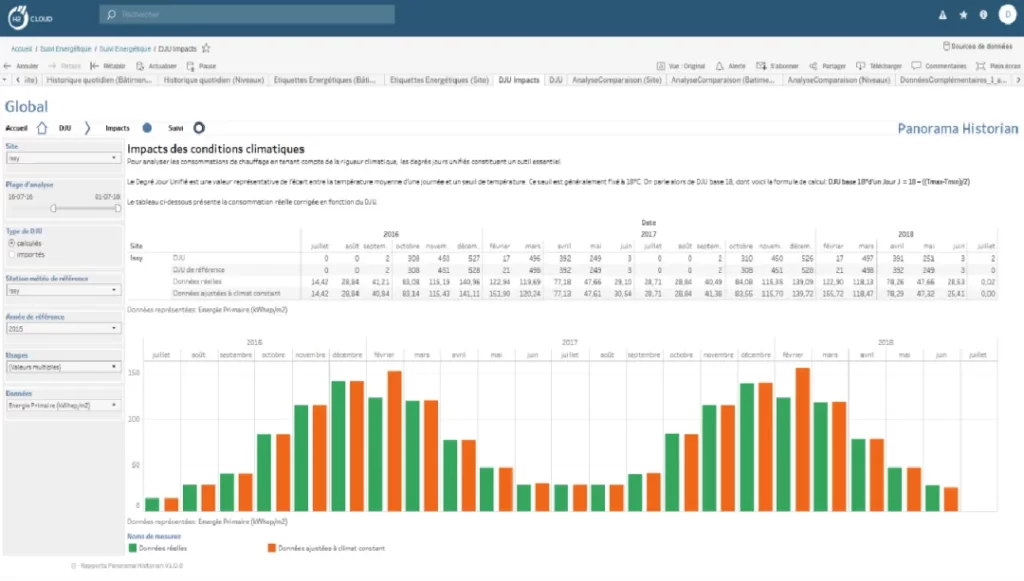

In complex commercial buildings, energy wastage is often the result of subtle deviations in a number of areas. For example:

Improper HVAC settings

Lighting not automatically adjusted according to occupancy

Data omissions lead to analytical bias

Modeling and algorithmic analysis through SCADA can reveal:

Energy efficiency KPI deviation

Energy flow imbalance between lighting and air conditioning systems

Early warning of potential waste through predictive algorithms

The Panorama SCADA platform enables cross-system energy consumption correlation analysis to help managers identify "deep inefficiencies" and continuously improve overall energy efficiency.

虹科結合 AR 智慧眼鏡與 AI 辨識技術,打造標準化 PCB 質檢工作流程,整合 MES、ERP、AOI 系統,降低漏檢率、提升良率,加速電子製造數位化升級。

深入解析虹科 GNSS 模擬器如何支援無人機整機測試,涵蓋多星座 GNSS 仿真、RTK 公分級定位、抗干擾測試與多感測器融合驗證,助力高效、安全的 UAV 研發。

增材製造(PBF-LB/M)中的高精度過程監控與誤差檢測,虹科 iDS USB3 工業相機助力粉末層、再熔化層與動態飛濺監控,提升部件品質與研發效率,適用航空航天、醫療、汽車等行業。