【虹科方案】從被動防禦到主動預防:用 KnowBe4 輕鬆應對關鍵基礎設施條例風險評估與審核

KnowBe4 為企業應對香港《關鍵基礎設施保護條例》提供了化繁為簡的解決方案。面對第 24 條與第 25 條的嚴格挑戰,它將難以量化的「人為風險」轉變為可追蹤的實戰數據,不僅彌補了傳統評估的盲點,更為年度審核提供了證明控制措施「有效運作」的鐵證。透過自動化報告與持續演練,企業能在大幅降低安全風險的同時,輕鬆滿足監管要求,實現從「被動合規」到「主動防禦」的關鍵轉型。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

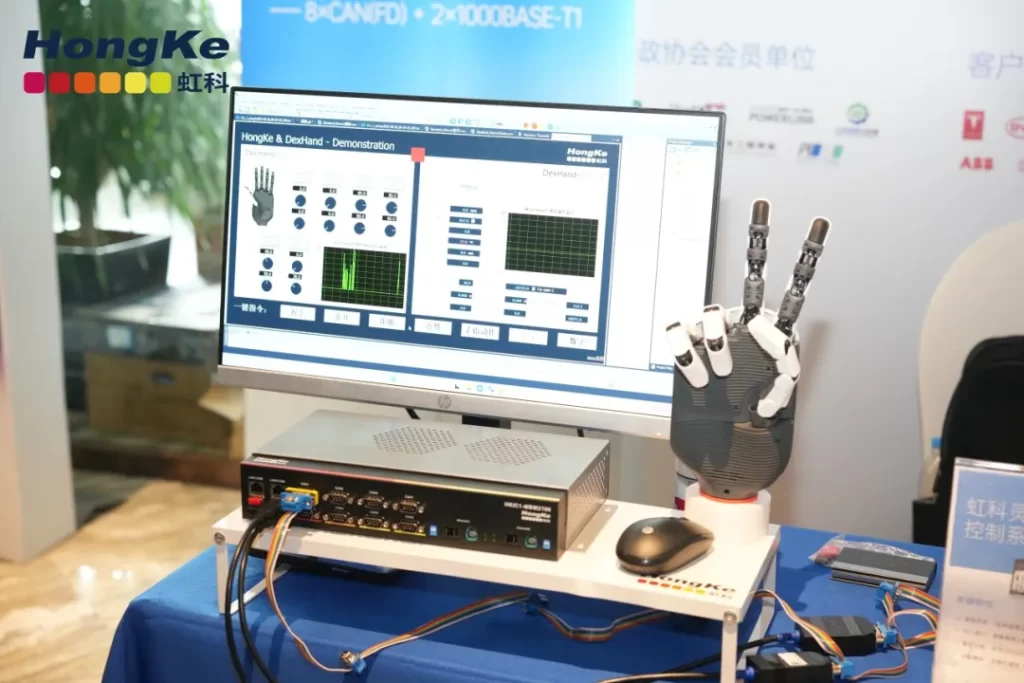

In the R&D landscape of humanoid robots, dexterous hands are the key bridge connecting technological conception and practical application. In order to realize millimeter-level motion and millinews-level force control, a set of efficient and accurate testing and verification program is the core guarantee for this pair of "robotic hands" to move from laboratory prototype to mass production.

The CAN FD technology-based test solution created by HONGKE is a deep integration of high-speed communication, intelligent monitoring and precise control, providing full-dimensional capability support for the R&D, quality inspection and application of the dexterous hand. The Smart Hand, which is the core execution task in this program, comes from HTC's partner, Smart Smart, and its excellent hardware performance provides a key carrier for the value verification of HTC's test program.

As the core execution part of humanoid robot, robot dexterous hand needs to be equipped with multi-degree-of-freedom movement, force sensing and precise operation ability, and its application scenarios cover various fields such as industrial sorting, medical rehabilitation and scientific research experiments.

In order to realize the precise testing of "millimeter-level motion and milli-Nm-level force control" of dexterous hands, the traditional communication and testing means have the pain points of insufficient bandwidth, poor real-time performance, and complicated data parsing.

In the robotics industry, EtherCAT or CAN FD is often used as the core communication protocol. Among them, CAN FD stands out for its stable transmission quality and extremely low cabling costs.

As an upgraded version of the traditional CAN bus, CAN FD raises the data segment transmission rate to 8 Mbps and extends the data load to 64 bytes per frame, while retaining the advantages of high reliability and real-time performance of the CAN bus, which is a perfect match for the needs of dexterous robots for "high-speed command transmission + multi-sensor data return".

With the core logic of "communication + monitoring + control", HONGKE's dexterous motion control solution builds up a complete verification link from signal acquisition to motion execution, so that every action and every set of data of the dexterous hand can be monitored and adjusted.

Supplied by Hongke's partner, Dexterous Intelligence, this dexterous hand features a high degree of freedom (e.g., 19DOF), high-precision force/position sensors, and a biomimetic structure design that reproduces anthropomorphic movements and fine manipulation, and is the core execution unit of the test solution.

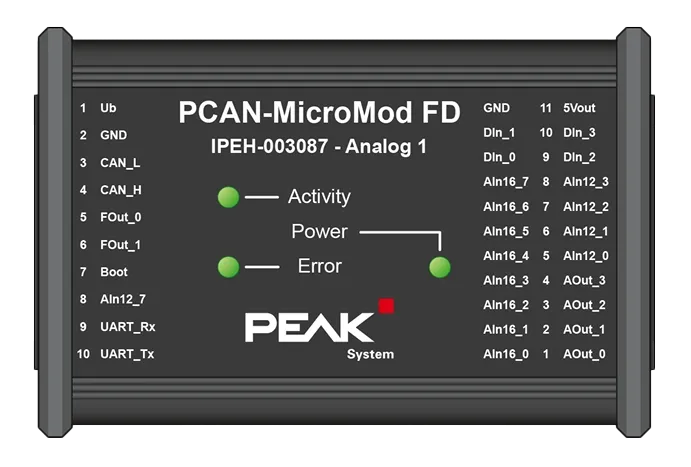

HONGKEI supports 8 CAN(FD) and 2 1000BASE-T1 bus workstations with 1 Mbps transmission rate for smart arbitration segment, 5 Mbps transmission rate for data segment, and 64-bit single frame load with 1-microsecond timestamping accuracy, which provides the hardware cornerstone for "high-speed command issuance + real-time data return".

HONGKE's Vehicle Network Communication Test Board is a high-performance industrial controller motherboard for monitoring, emulating, and simulating CAN(FD) and T1 network messages with powerful data processing and communication capabilities. It integrates 8 CAN(FD) interfaces and 2 1000BASE-T1 interfaces, and is compatible with PCAN underlay driver, which meets the test and data transmission requirements in complex communication network environments, and is widely used in automotive research and development, intelligent transportation, and vehicle inspection.

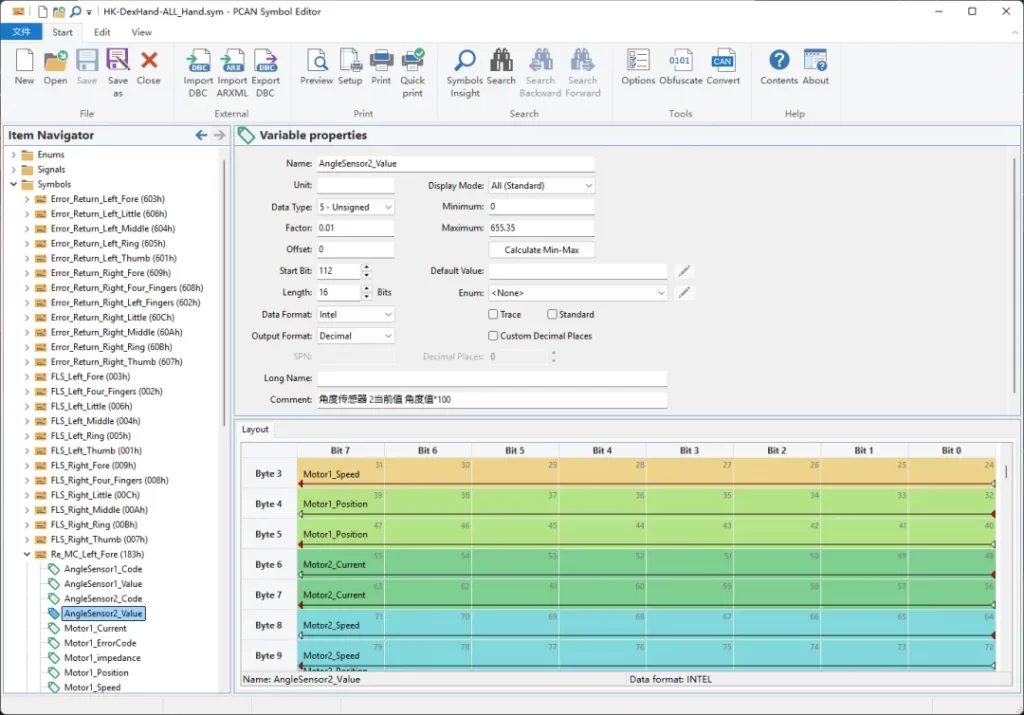

Based on HONGKE's PCAN-Explorer 6, the software platform is specially adapted to the communication protocols of the Dexterity Smart Hand, making the complex testing process simple and efficient:

Instantly collects and analyzes the multi-dimensional signals from the motor current, temperature, angle sensor, force sensor, etc. of the dexterous hand, and presents them in the form of graphs and charts (as shown in this article's "Left and Right Hand Software Monitoring Chart", you can independently monitor the status of the motor and sensor data of the left hand and the right hand, respectively).

It supports one-touch motion command sending for key gestures, and also realizes fine motion control for single-joint and multi-joint through the parameterized interface, with a measured delay deviation of less than 5 microseconds to meet the synchronization requirements of milli-Nm force control.

Converts raw data on the CAN FD bus into easy-to-understand physical quantities through database file parsing and supports data logging, offline analysis and fault tracing.

The whole system deployment process is simple and efficient, and no complicated professional operation is required to complete the test preparation.

As shown in the figure, the whole system consists of Dexterous Intelligent Smart Hands, HONGKE BUS workstations and the host computer (running HONGKE PCAN-Explorer 6 customization project).

After completing the hardware connection, the "Bus Configuration" module of Avision PCAN-Explorer 6 can be used to set the CAN FD communication parameters (e.g., baud rate, communication data, etc.) to establish a high-speed communication link between the dexterous hand and the test tool.

In the Symbol Editor of the PCAN-Explorer 6 software, you can freely create a CAN (FD) bus-based communication database, including descriptions of specific messages and signals, layout configurations, and various data parameters that may be used in virtual variables or customized projects.

By loading database files, customized projects can be advanced from the "link level" to the "application level", allowing even non-technical people to complete basic communication tests and command drivers with this set of customized projects:

Motor status monitoringReal-time monitoring of motor speed, position, current and temperature to ensure safe operation.

Sensor Data MonitoringAnalyze the output of angle sensors and force sensors (normal force, tangential force) to verify the positional accuracy and force control performance.

Communication status monitoringReal-time tracking of CAN FD bus load rate and error frames to ensure communication link stability.

Based on the CAN FD technology, the HONGKEI robotics dexterity test solution constructs a complete, high-precision full-link test system through the deep synergy of hardware and software.

With the professional technical structure of "hardware accurate transmission + software intelligent analysis" and the strict logic of traceability of the whole chain data and reproducibility of the testing process, the solution not only provides quantitative support for the iteration of dexterous hand technology, but also becomes an important technological benchmark for the development of standardization and precision in the robotics industry.

At present, the dexterous hand has been applied in mass production in the fields of industrial sorting and power inspection, etc., and the solution will continue to provide reliable technical guarantee and testing support for its industrialization and large-scale landing.

KnowBe4 為企業應對香港《關鍵基礎設施保護條例》提供了化繁為簡的解決方案。面對第 24 條與第 25 條的嚴格挑戰,它將難以量化的「人為風險」轉變為可追蹤的實戰數據,不僅彌補了傳統評估的盲點,更為年度審核提供了證明控制措施「有效運作」的鐵證。透過自動化報告與持續演練,企業能在大幅降低安全風險的同時,輕鬆滿足監管要求,實現從「被動合規」到「主動防禦」的關鍵轉型。

安鵬精密於實際 NVH 路測中,透過虹科 PCAN-MicroMod FD,將車輛 CAN / CAN FD 訊號即時轉換為類比電壓,無需二次開發即可完成訊號同步,低成本整合既有 NVH 資料採集系統。

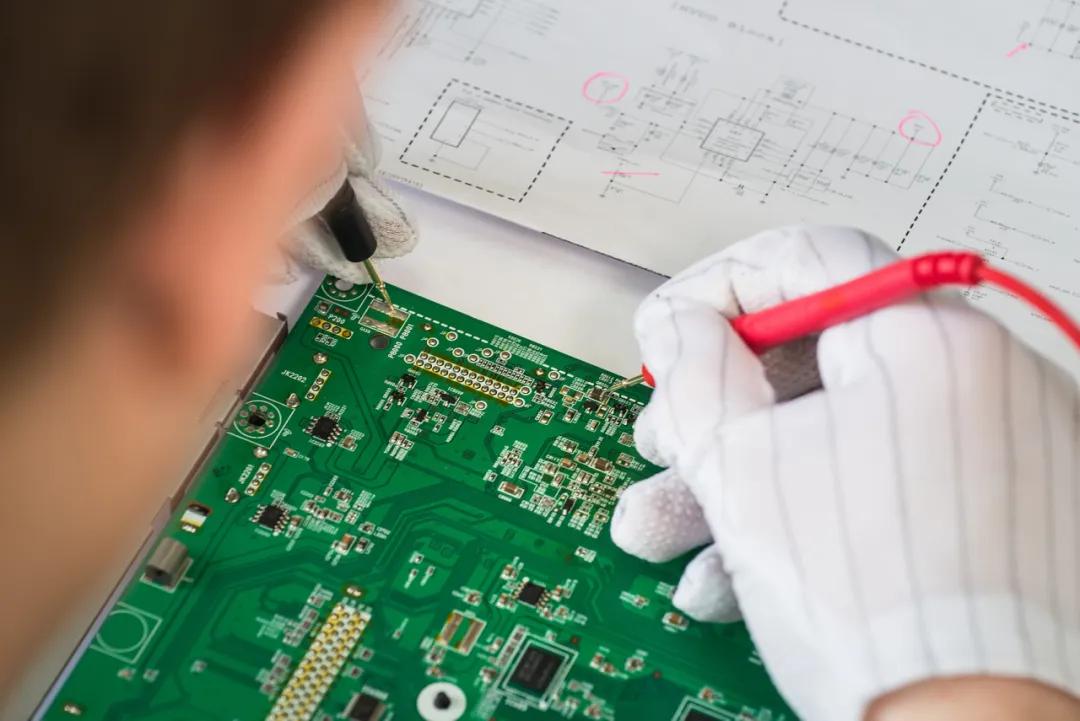

虹科結合 AR 智慧眼鏡與 AI 辨識技術,打造標準化 PCB 質檢工作流程,整合 MES、ERP、AOI 系統,降低漏檢率、提升良率,加速電子製造數位化升級。