【虹科方案】從被動防禦到主動預防:用 KnowBe4 輕鬆應對關鍵基礎設施條例風險評估與審核

KnowBe4 為企業應對香港《關鍵基礎設施保護條例》提供了化繁為簡的解決方案。面對第 24 條與第 25 條的嚴格挑戰,它將難以量化的「人為風險」轉變為可追蹤的實戰數據,不僅彌補了傳統評估的盲點,更為年度審核提供了證明控制措施「有效運作」的鐵證。透過自動化報告與持續演練,企業能在大幅降低安全風險的同時,輕鬆滿足監管要求,實現從「被動合規」到「主動防禦」的關鍵轉型。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

With the rapid development of Software-Defined Vehicles (SDV) and centralized E/E Architecture, traditional CAN buses can no longer support the increasing volume of data and real-time control requirements.

Leveraging our deep experience in automotive network communication, embedded systems and FPGA technology, we have proposed a new technology based on CAN XL × TSN (Time-Sensitive Networking) It is a total solution that enables vehicle manufacturers and Tier-1 suppliers to build efficient, reliable and scalable in-vehicle communication networks of the future.

CAN XL (Controller Area Network eXtended Layer) is the third-generation protocol for CAN networks, combining the three core advantages of "low cost," "high stability," and "strong compatibility," and realizing a cross-generation performance leap through the new design of the physical and protocol layers.

Its main technical features include:

Ultra-high-speed transmission capability: Data rate up to 1-20 Mbit/s (arbitration domain ≤1 Mbit/s, data domain 1-20 Mbit/s)

Data length extension: Supports 1-2048 Byte, far exceeding CAN FD's 64 Byte limit.

Virtual CAN Network (VCID): Supports up to 256 logical virtual networks for greater isolation and flexibility

Multi-Protocol Compatibility: New SDT (Service Data Unit Type) field for interoperability with protocols such as Ethernet.

Hao Chen, Head of Technology at Rainbow Technology, pointed out that CAN XL is a new technology in the ADAS and in-vehicle radar systems This is a significant advantage in the current 2M CAN FD architecture. In the current 2M CAN FD architecture, for example, radar data needs to be split into multiple frames and re-synchronized by the ADAS controller, whereas CAN XL can utilize Single frame 2K payload Transmits all object data at once, dramatically improving synchronization and real-time performance.

In order to help the industry to experience this new standard quickly, HONGKE launched the PCAN XL KitThe content:

USB-to-CAN XL Interface Module

Professional CAN Analysis Software PCAN-Explorer 7

PCAN-Basic SDK programming interface

The kit fully supports CAN CC / FD / XL communications and implements the core functionality of the CAN XL protocol in an FPGA, providing a complete environment for development, test and verification.

As the electrification and intelligence of automobiles increase, the E/E architecture is moving from the traditional decentralized ECU to the "domain controller" and "central computing" forms. In this process, vehicle communication faces five major challenges:

Explosive growth in arithmetic demand

Slow hardware iteration

Fragmentation of communication interfaces and protocols

Increased real-time and functional safety requirements

Cost and Flexibility Contradictions Highlighted

Mr. Law Hin-chi, Senior TSN Engineer of HTC, pointed out thatFPGAs are the "software" of hardware.The three characteristics of "parallel processing", "low latency" and "reconfigurability" can precisely meet the above challenges.

Unlike CPU/GPU time-sharing, FPGAs use space-sharing, where each task is executed simultaneously by independent circuits, realizing true hardware-level certainty.

The FPGA-based TSN (Time Sensitive Networking) solution brings three core values to the automotive E/E architecture:

Breaking the performance bottleneck: Hardware latency in microseconds for ultra-low jitter communication

Unified Communications Architecture: Single chip replaces multiple discrete controllers, supports any-to-any protocol conversion

Upgrade for the future: Adaptation of new standards through OTA reorganization to perfectly match software-defined vehicle requirements

The complete range of FPGA TSN solutions from SOC-E / RelyUm Series TSN IP Cores and Boards,TSN Switches until (a time) Test and Verification Kits The product supports 10M / 100M / 1G / 2.5G multi-rate. The product supports 10M / 100M / 1G / 2.5G multi-rate, and built-in IEEE 802.1AS time synchronization, 802.1Qbv time-aware shaping, and other key TSN standards, which makes it easy to build a highly reliable and accurate in-vehicle network.

CAN XL and TSN are not in competition, but complement each other and work together. The former provides high bandwidth and low cost for low and medium-speed control layers, while the latter provides certainty and high reliability for high-speed backbone networks. In the Central + Zonal Architecture, the combination of the two is driving the automotive industry towards a more efficient and reliable network. Software-Defined Mobility A New Era.

As the automotive E/E architecture evolves from distributed ECUs to domain control, and then to a "centralized computing + domain control" system, the deep convergence of CAN XL and TSN will become a key force in the evolution of in-vehicle networks, laying the foundation for in-vehicle communication, safety and sustainable innovation.

KnowBe4 為企業應對香港《關鍵基礎設施保護條例》提供了化繁為簡的解決方案。面對第 24 條與第 25 條的嚴格挑戰,它將難以量化的「人為風險」轉變為可追蹤的實戰數據,不僅彌補了傳統評估的盲點,更為年度審核提供了證明控制措施「有效運作」的鐵證。透過自動化報告與持續演練,企業能在大幅降低安全風險的同時,輕鬆滿足監管要求,實現從「被動合規」到「主動防禦」的關鍵轉型。

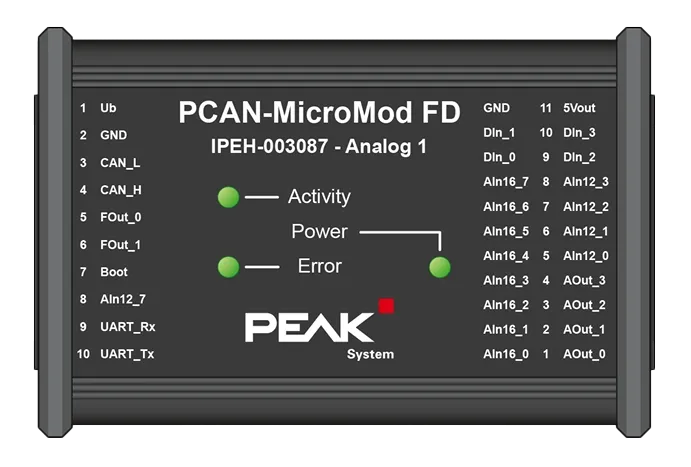

安鵬精密於實際 NVH 路測中,透過虹科 PCAN-MicroMod FD,將車輛 CAN / CAN FD 訊號即時轉換為類比電壓,無需二次開發即可完成訊號同步,低成本整合既有 NVH 資料採集系統。

虹科結合 AR 智慧眼鏡與 AI 辨識技術,打造標準化 PCB 質檢工作流程,整合 MES、ERP、AOI 系統,降低漏檢率、提升良率,加速電子製造數位化升級。