- Home

- Technical Products

Enterprise Cloud IT Solutions

Test Measurement

Industrial Measurement

- Solutions

Enterprise Cloud IT Solutions

Test Measurement

- Latest Articles

- About Us

EN

EN

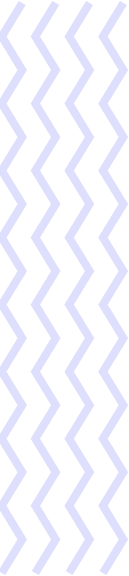

Ensenso 3D Stereo Camera X-Series

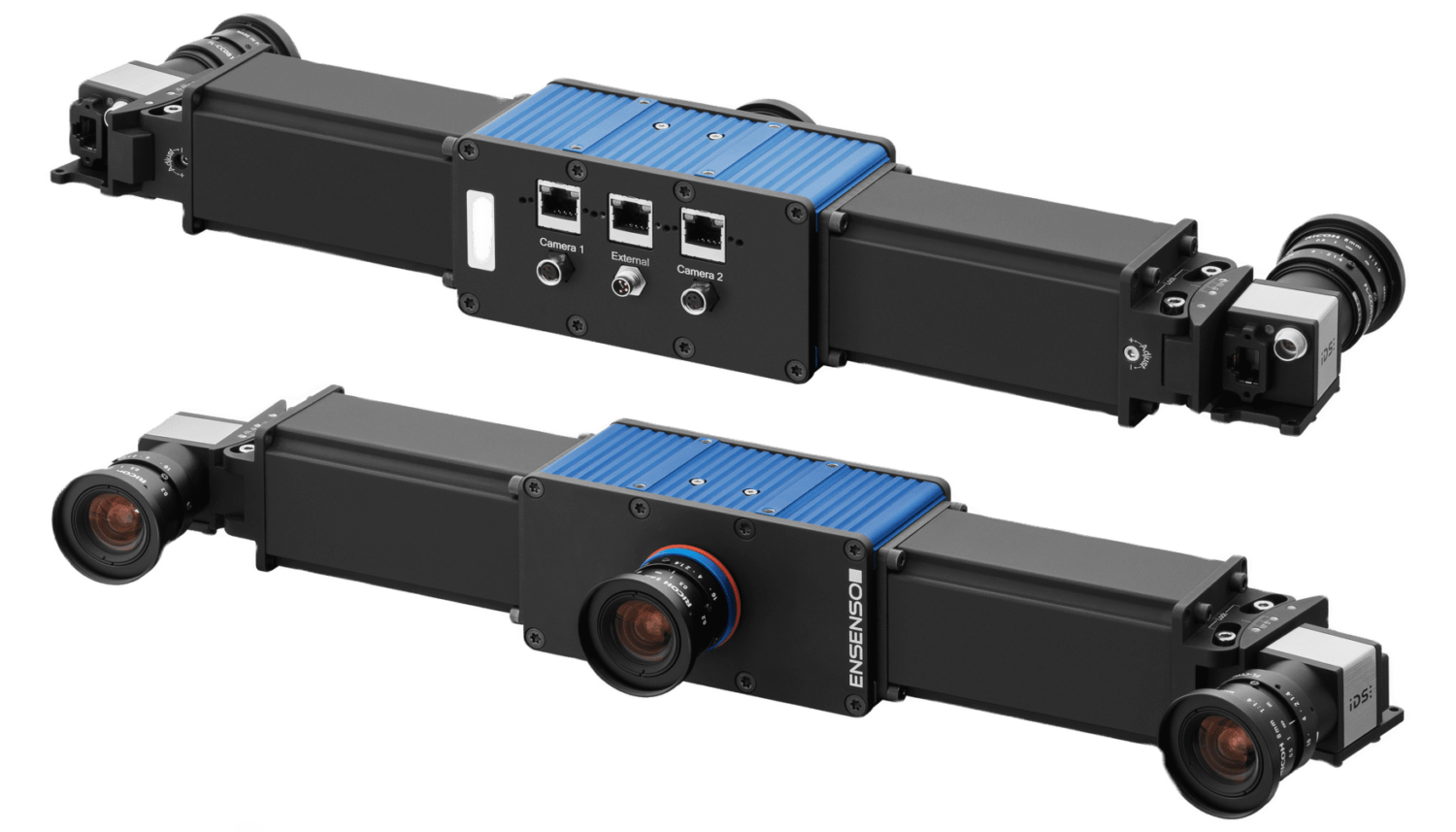

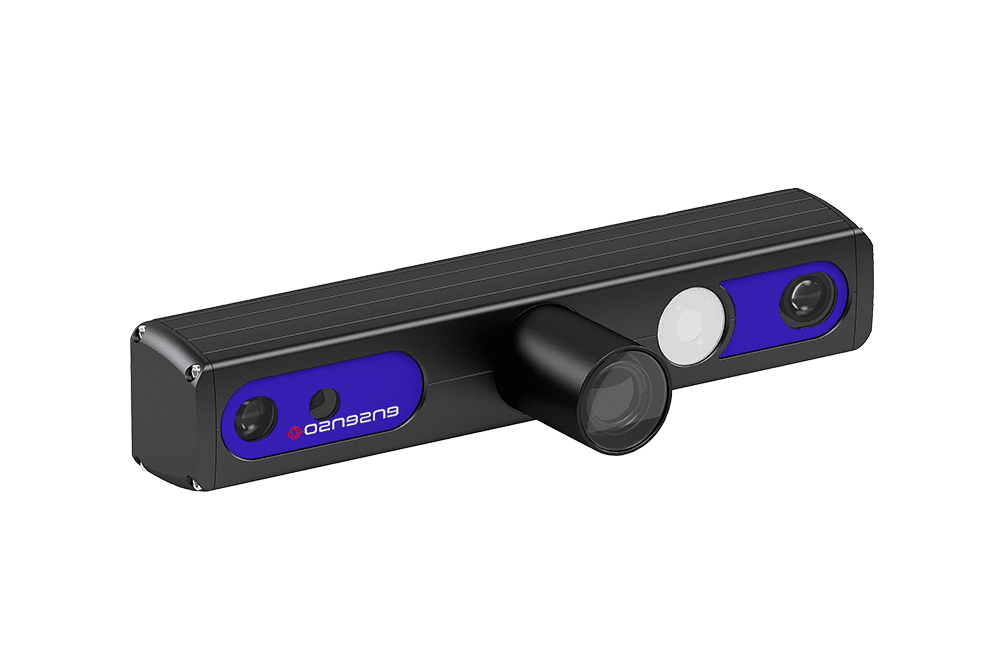

Flexible Adjustment - Modularization, Adaptation to Individual Needs

- Ideal for collaborative robots with a compact and robust 3D camera system designed for use in harsh environmental conditions.

- Integrated projector structure easily captures objects with textureless surfaces, providing highly accurate images even in outdoor, difficult lighting conditions.

- Working distance up to 3 meters, real-time 3D data, full resolution up to 30 frames/sec.

Ensenso X-Series 3D Vision Camera

The Ensenso X-Series cameras feature a modular 3D camera system that allows for greater flexibility and precision in camera applications, with variable baselines, adjustable viewing angles, and a wide range of lens options to suit your individual needs. Meanwhile, the projector's module is equipped with 100W LED high power projection to ensure image capture in outdoor or low-light environments. The working distance can be extended up to 5 meters.

- For use in harsh environments: IP65/67 rated protection against dirt, dust, and splashing water.

- For use in difficult lighting conditions: 100W LEDs for easy capture of object images.

- Flexibility to adapt to work requirements: variable baseline, adjustable viewing angle, a variety of lens options

- Working distance up to 5m: Larger working distance extension.

- Integrated Gigabit Ethernet: Customized 3D Camera System with Eye CP Camera

- Capture objects up to 8m³ in volume: Adjustable camera mounting extension working distance.

- FlexView1&2 Multi-Image Acquisition Technology: Providing Higher Accuracy

- High resolution option: 1.6/5.0 megapixel cameras are available to meet your needs.

- The Ensenso SDK is easy to set up and operate: it also includes a GPU-based GigE interface for image processing.

Robotics Automation

Robots utilize data captured by 3D cameras for precise part grabbing, assembly and welding.

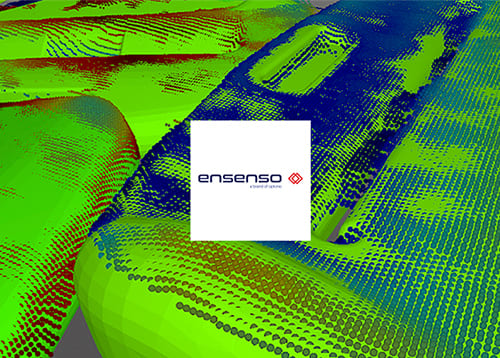

Quality Inspection and Testing

3D cameras are used to check the quality, size, integrity or location of products, such as automotive parts detection, workpiece surface defect detection, parts modeling, etc.

Logistics and Warehouse Automation

3D camera for automated parcel sorting or cargo stacking, such as feeding, palletizing/unloading, warehouse picking

Medical and Biomedical Imaging

3D cameras are used for body scanning, surgical assistance, or for imaging in other medical applications.

Product Advantages

Quick Capture

Precision Measurement

Compact and lightweight

Variable Basis

Easy to use

IP65/67 Protection

100W Projector

FlexView2 High Precision Technology

Flexibly adjustable to provide a high level of protection options to facilitate project personalization needs.

- Camera stands are available in a range ofDifferent widthsThe baseline configuration can be realized in different sizes.

- as wellSelf-adjusting camera angleThe C-lens is the most suitable focal length to be installed on the camera and projector from a wide range of C-lenses.

- Flexibility in adjustability facilitates a variety of settings at working distances of more than five meters, allowing the user to capture theVolume of objects over cubic metersFor example, large heavy pallets or entire rooms.

- X30/X36 with IP65/67 protection options.Protects the camera from dust, splashes or any liquid cleaners.It also prevents accidental changes to the lens settings.

- You can choose to use1.6 million resolutionThe camera, or5 megapixel resolutionThe camera is designed to cope with applications that require a larger field of view and greater detail.

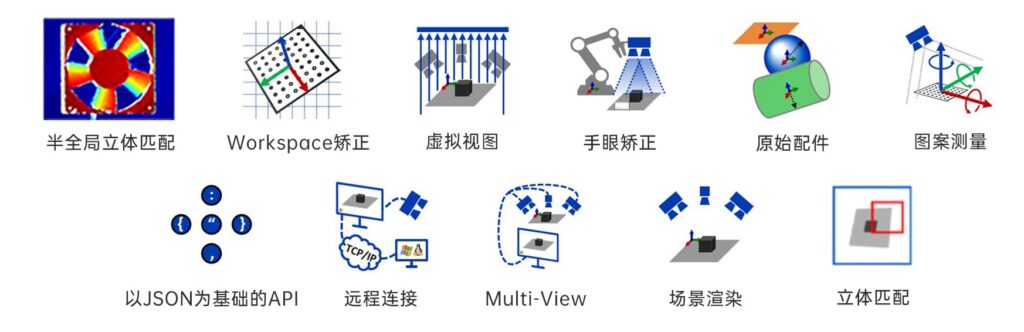

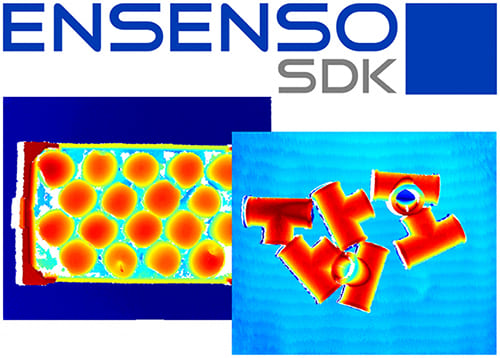

Ensenso SDK is provided for easy operation of the product.

With the Ensenso SDK, the Ensenso N Camera Series cameras are easy to set up and operate.

In addition to providing easy-to-configure wizards and camera calibration support for 3D cameras, it also includes GPU-based image processing for faster 3D data processing.

More Products

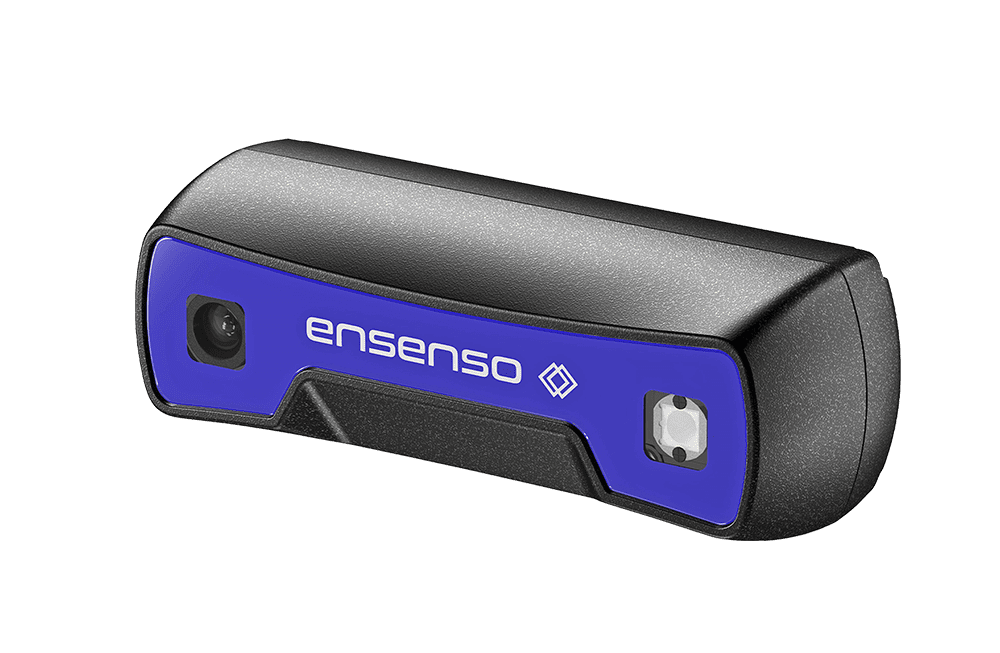

S-Series 3D Stereo Camera

Ultra compact, high precision depth, TOF principle

Utilizes AI's 3D laser dot-matrix pattern triangulation technology for multiple scenes and ultra-compact designs.

C-Series Color RGB 3D Stereo Camera

Equipped with fully integrated RGB sensor

Various models are available with a choice of baseline length (S:240 mm, M:455 mm) and focal length.

N Series 3D Stereo Camera

Precise, robust, easy to use

Compact and rugged 3D camera system designed for use in harsh environmental conditions

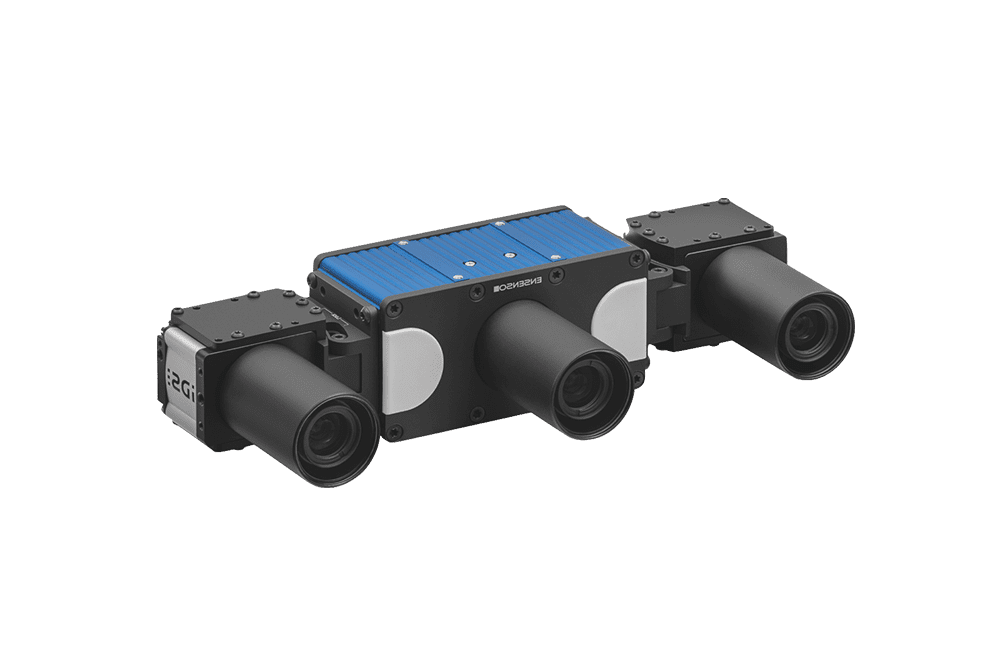

XR Series Modular 3D Stereo Camera

Modular, local data processing capabilities

Performs 2D image matching operations directly on the camera side, and generates 3D point cloud data on the camera side for transfer to a computer.

Frequently Asked Questions

Technical support and paid services to drive your project to the limit.

What are the features of the different 3D cameras in the S-Series, N-Series, X-Series and XR-Series?

S series camera with the other three series of different technical principles applied, S series application is TOF laser triangulation principle, mainly rely on the laser transmitter and receiver to collect distance information, fixed field of view, high frame rate, low price. The other three series are applied to the principle of binocular scattering, high precision, of which the X series compared to the N series, the lens external, you can easily adjust the angle of the two cameras to adjust the field of view, and stronger anti-sunlight performance. The XR series supports data processing on the camera side, which can release the computing pressure on the processor side of the industrial control machine and improve efficiency.

FlexView is our core patented technology. The principle of FlexView is to capture 8 or 16 pairs of images from the left and right cameras at the same time, and then integrate the results of the multiple pairs of images into a single image, resulting in a depth image with higher precision, reliability, and finer details.

We apply the principle of binocular plus projector projection random scattering texture, in the traditional binocular parallax calculation measurement principle, an additional projector active projection texture to the target object, when the target object is not enough features, the images collected by the two cameras can be accurately parallax calculation, and then get the depth image and 3D point cloud.

1. What is the content of the test? Does the size/shape vary? What is the size range? Can you provide pictures/video?

2. Is the test in motion or static? Outdoor or indoor? Can you provide a movie of the working environment?

3. How long does the camera work?

4. Precision requirements?

5. Need RGB information?

6. Is the visual processing software being developed in-house or by a third party?

There are 3 holes for PoE, one round hole for the power adapter, and two network cable connectors, the one labeled OUT connects to the camera's network port, and the one labeled IN connects to the control terminal (e.g., computer).

- Our 3D cameras use the binocular scattering principle, which is capable of handling even difficult lighting conditions. And with our patented FlecView technology, both moving and stationary objects can be detected with an accuracy of up to about 0.1mm.

- We are modular, lightweight design, small and flexible, because the size will affect the robot/system design and carrier design, which is especially important for the collaborative robot, the camera is too heavy will occupy the payload of the arm.

- We provide C, C++, C#, Halcon, and ros interface APIs, which are convenient for users to develop and use. And our SDK is very stable and easy to use, which is very important for the long-term use of enterprises and product reputation. This is also the reason why many leading companies, such as Mitsubishi, Damien, Makin, Amazon, etc., choose us.

- The protection level is IP65/67, supporting a wide range of indoor and outdoor scenarios, and adapting to harsh environments such as industrial applications.

Open PC Control Panel->Network and Sharing Center->Change Adapter Settings->Select the right-click attribute of the Ethernet you just connected->Select IPv4->Assign IP address.

1. What is the content of the test? Does the size/shape vary? What is the size range? Can you provide pictures/video?

2. Is the test in motion or static? Outdoor or indoor? Can you provide a movie of the working environment?

3. How long does the camera work?

4. Precision requirements?

5. Need RGB information?

6. Is the visual processing software being developed in-house or by a third party?

Professional technical support from HONGKEI to help you succeed in your project.

HongKe provides professional IDS industrial cameras and 3D imaging solutions, including uEye CMOS, NXT AI smart cameras, Ensenso 3D series and event cameras. The cameras are equipped with high sensitivity, low latency, and accurate image processing capabilities, and support various interfaces such as GigE and USB3.0, which can satisfy a wide range of applications such as machine vision, intelligent manufacturing, medical imaging, and automated inspection. With flexible development interface and strong software support, IDS cameras help enterprises build efficient and stable image recognition and AI vision systems, and become the key eyes of the new generation of intelligent industries.