【虹科方案】從被動防禦到主動預防:用 KnowBe4 輕鬆應對關鍵基礎設施條例風險評估與審核

KnowBe4 為企業應對香港《關鍵基礎設施保護條例》提供了化繁為簡的解決方案。面對第 24 條與第 25 條的嚴格挑戰,它將難以量化的「人為風險」轉變為可追蹤的實戰數據,不僅彌補了傳統評估的盲點,更為年度審核提供了證明控制措施「有效運作」的鐵證。透過自動化報告與持續演練,企業能在大幅降低安全風險的同時,輕鬆滿足監管要求,實現從「被動合規」到「主動防禦」的關鍵轉型。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

In the process of drug research and development and production, a seemingly simple capsule actually involves a complex preparation process and high-precision control technology. The uniform dissolution and mixing of the capsule contents is the key to determining the quality and efficacy of the drug.

Drip method: The gelatin solution is wrapped around the liquid and dropped into the coolant to form a spherical pellet;

Pressing methodThe medicine is sandwiched between two sheets of plastic and then pressed into a steel mold.

Regardless of which capsule molding method is used, the premise is that the raw materials of the drug must beDissolve and homogenizeThis is the only way to ensure the accuracy and bioavailability of the final dosage.

In the capsule manufacturing process, numerous pharmaceutical ingredients need to beSpecific TemperatureThe shaker equipment plays a key role in the formation of a stable solution or suspension by fully dissolving and mixing under the shaker.

If the mixing is not efficient enough, it may result in:

Incomplete dissolution of the drug;

Uneven formulation;

Eventually, the capsule contents become unstable, affecting quality and consistency.

HONGKE Grant OLS-26 Circumferential Reciprocating Shaker provides the following four core functions to meet the high demands of dissolution and mixing in pharmaceutical capsule manufacturing process:

1. Dual-mode oscillation system for efficient mixing

It also supports two modes of oscillation, circular and reciprocal, to automatically adjust the mixing rhythm according to the different viscosities of the liquid, and effectively improve the homogeneity and dissolution rate of the raw materials.

2. Precise temperature control to ensure process consistency.

Equipped with a digital PID temperature control system and a sensitive PT1000 probe, the temperature range is from ambient +5°C to 99°C with a stability of ±0.1°C, which ensures that sensitive materials are dissolved under consistent conditions.

Adopting magnetic coupling oscillation and Heat mat heating membrane technology, the sink has no exposed heating filament, anti-corrosion and anti-electricity leakage, which strengthens the safety of the laboratory and prolongs the service life of the equipment.

Built-in audible reminder countdown timer, self-defined high temperature alarm and power failure protection functions, realizing full sample protection and process accuracy.

Since the introduction of "Hongke Grant OLS-26 Water Bath Shaker" to a well-known pharmaceutical company in China, the equipment has been running continuously and stably for more than five years, and the performance of the equipment is still outstanding as it has been undertaking the key raw material dissolution process for a long time.

Usage practices have shown that the OLS-26 has the following distinct advantages:

low failure rate: Magnetic coupling drive reduces wear and tear and lowers maintenance frequency;

Stable operationThe oscillation is highly stable over a wide range of speeds;

Anti-corrosion design: Stainless steel sinks with high alloy steel components to meet the needs of pharmaceutical laboratories;

Easy MaintenancePlug and play type drain valve, simple interface, greatly reduce maintenance difficulties.

In the high-standardPharmaceutical Manufacturing and Quality Control ProcessesThe reliability and stability of the equipment determines the consistency and safety of the final product.

Hongke Grant OLS-26 water bath shaker provides strong support for capsule dissolution and mixing with its excellent mixing capability, temperature control accuracy, long-lasting durable design and intelligent operation experience.

🌟 Five years of stable operation is not the end, but the beginning of the high quality of Hongke OLS-26. Choosing Hongke is to choose the commitment to the quality of drugs and to be responsible for the safety of patients.

KnowBe4 為企業應對香港《關鍵基礎設施保護條例》提供了化繁為簡的解決方案。面對第 24 條與第 25 條的嚴格挑戰,它將難以量化的「人為風險」轉變為可追蹤的實戰數據,不僅彌補了傳統評估的盲點,更為年度審核提供了證明控制措施「有效運作」的鐵證。透過自動化報告與持續演練,企業能在大幅降低安全風險的同時,輕鬆滿足監管要求,實現從「被動合規」到「主動防禦」的關鍵轉型。

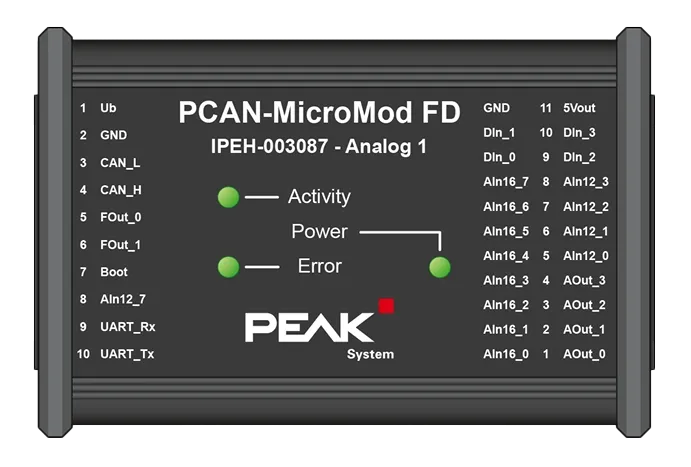

安鵬精密於實際 NVH 路測中,透過虹科 PCAN-MicroMod FD,將車輛 CAN / CAN FD 訊號即時轉換為類比電壓,無需二次開發即可完成訊號同步,低成本整合既有 NVH 資料採集系統。

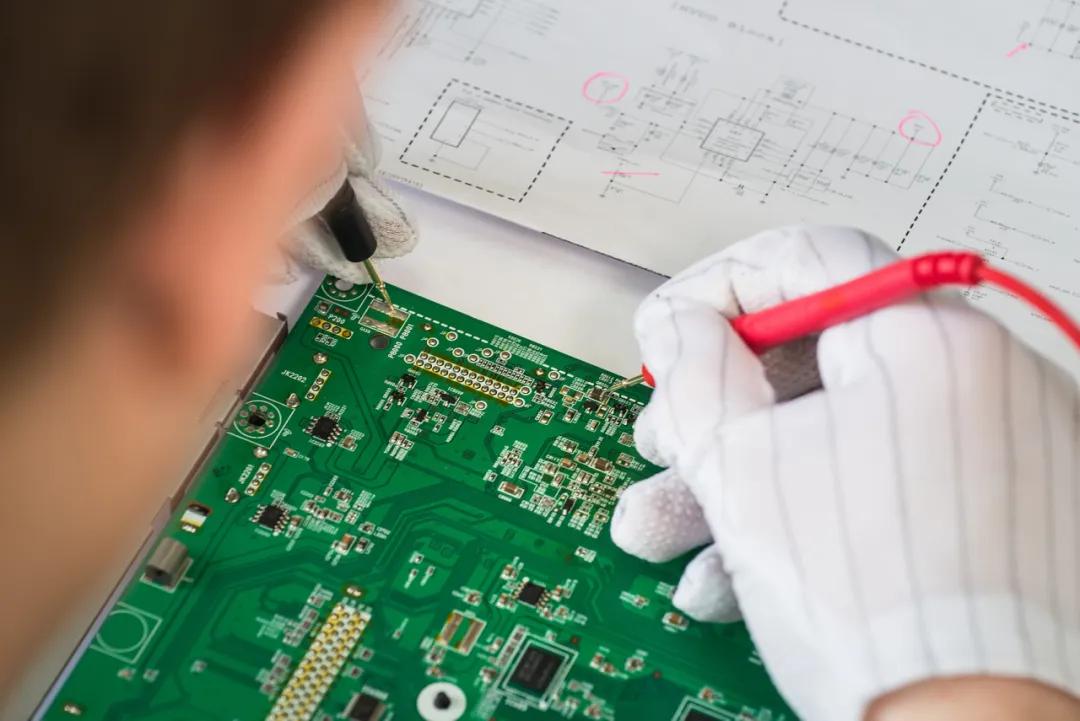

虹科結合 AR 智慧眼鏡與 AI 辨識技術,打造標準化 PCB 質檢工作流程,整合 MES、ERP、AOI 系統,降低漏檢率、提升良率,加速電子製造數位化升級。