【虹科方案】虹科 AR 遠程醫療解決方案 – 整合 AI 翻譯與遠程會診,推動跨國醫療合作

虹科 AR 遠程醫療解決方案整合醫療級 AR 智慧眼鏡、AI 即時翻譯與遠程會診技術,支援跨語言醫療溝通、臨床教學與國際醫療合作,推動智慧醫療流程數位化升級。

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

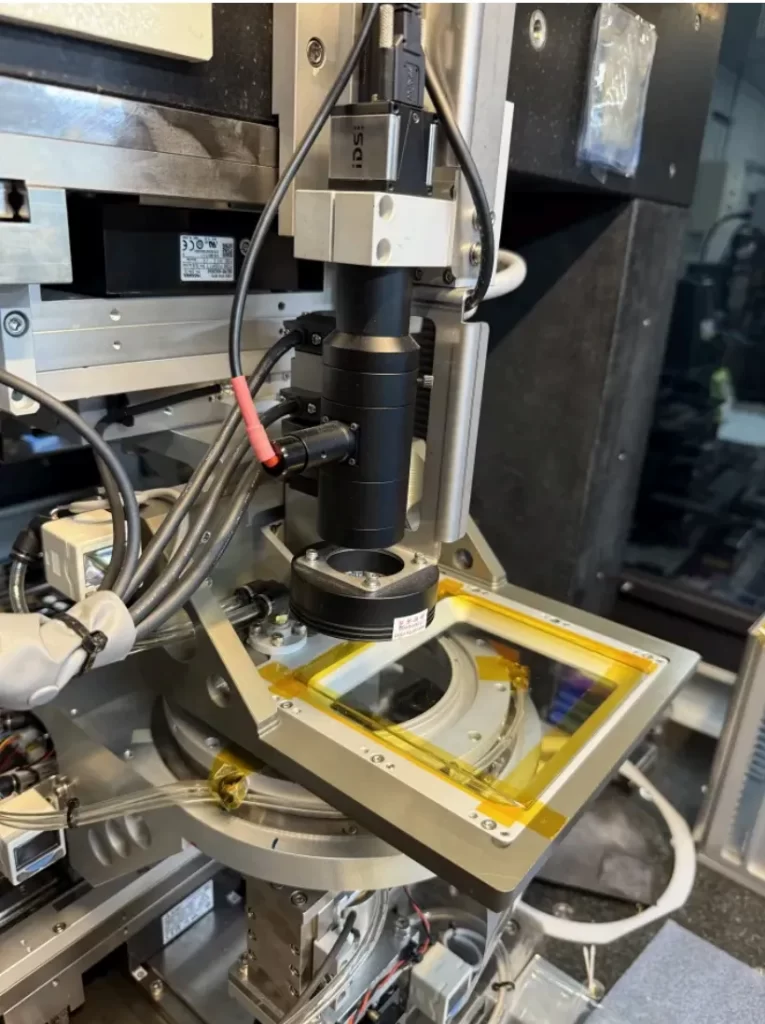

As Micro-LED display technology and advanced semiconductor components continue to push the limits of miniaturization and high performance, the process of Accuracy and Scalability It's more critical than ever. Technology leader Micraft Systems Plus has developed two future-proof high-end machines:

Micro-LED Laser Welder and HBM High Precision Wafer LaminatorThe

Both systems utilize USB3 uEye CP Series Industrial Camera from IDS, a co-brand of HTCThe system is designed to achieve the ultimate in precision, speed and process control. It has already been deployed in volume in the Asian electronics manufacturing market.

The Micro-LED laser soldering machine is designed for high speed and accurate transfer operations on large substrates (e.g. G4.5, G6 glass). Laser welding minimizes thermal and mechanical stresses, and is especially suited for applications where thousands of micro components are handled simultaneously.

The camera is first responsible for acquiring global datum marks to establish the relative position of the substrate in the machine's coordinate system; the positioning information is then transmitted to the motion control system so that the overall mechanism can be ±1 µm repeatability Completes high-precision movements.

After the fitting stage, the camera performs datum acquisition to realize the Real-time sub-micron alignmentIt also automatically performs dynamic rotation correction when necessary. This critical information guides the motion system to make position/angle corrections to ensure that each Micro-LED is perfectly aligned with the target pixel.

This system has a capacity of up to 10 million wafers per hour (cph).The combination of extremely high precision and large-scale mass production capability is an important KPI for expanding Micro-LED volume production.

The camera can automatically move to the inspection area to assist the operator with quick quality confirmation, including:

The IDS USB3 uEye CP camera (model U3-3800CP-M-GL Rev. 2.2), a co-brand of Avision, plays a key role in supporting the entire Micro-LED production process:

Damien Wang, IDS Regional Manager for Asia Pacific, said:"High-resolution and low-noise images capture even the smallest imperfections and are essential for high-precision processes."

The U3-3800CP utilizes the Sony STARVIS IMX183 (20.44 megapixels, 2.4 µm pixel size, 19.8 fps) to maintain excellent image quality in low light and high-speed scenes.

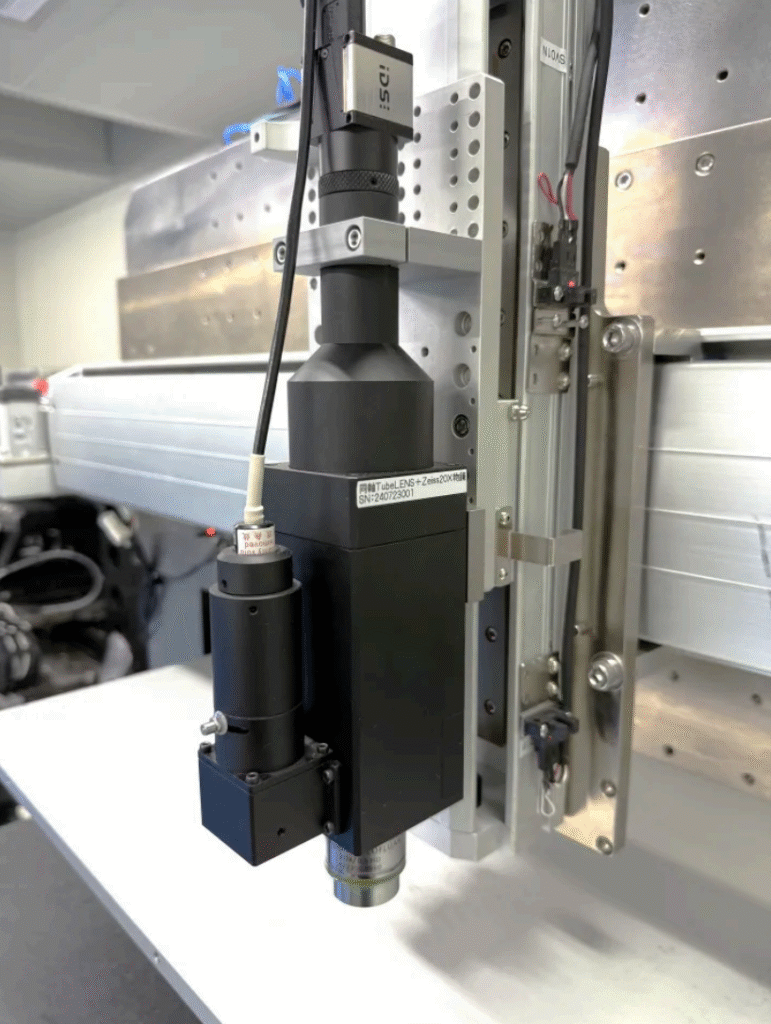

HBM's advanced wafer laminators are designed for high-density semiconductor packaging, especially for vertical stacking (3D stacking) processes that require micron-level precision.

The system is operated with two IDS U3-3890CP-M-GL Rev.2.2:

After the camera captures the data, the motion control system completes the precision alignment, ensuring consistent solder joints and avoiding thermal or electrical problems caused by micron-level deviations, even in high-density packages such as HBM.

The U3-3890CP features the Sony STARVIS IMX226 (12 megapixels, 1.85 µm pixel size, 33.2 fps), featuring:

Ideal for high-precision visual positioning required in 2.5D and 3D packaging.

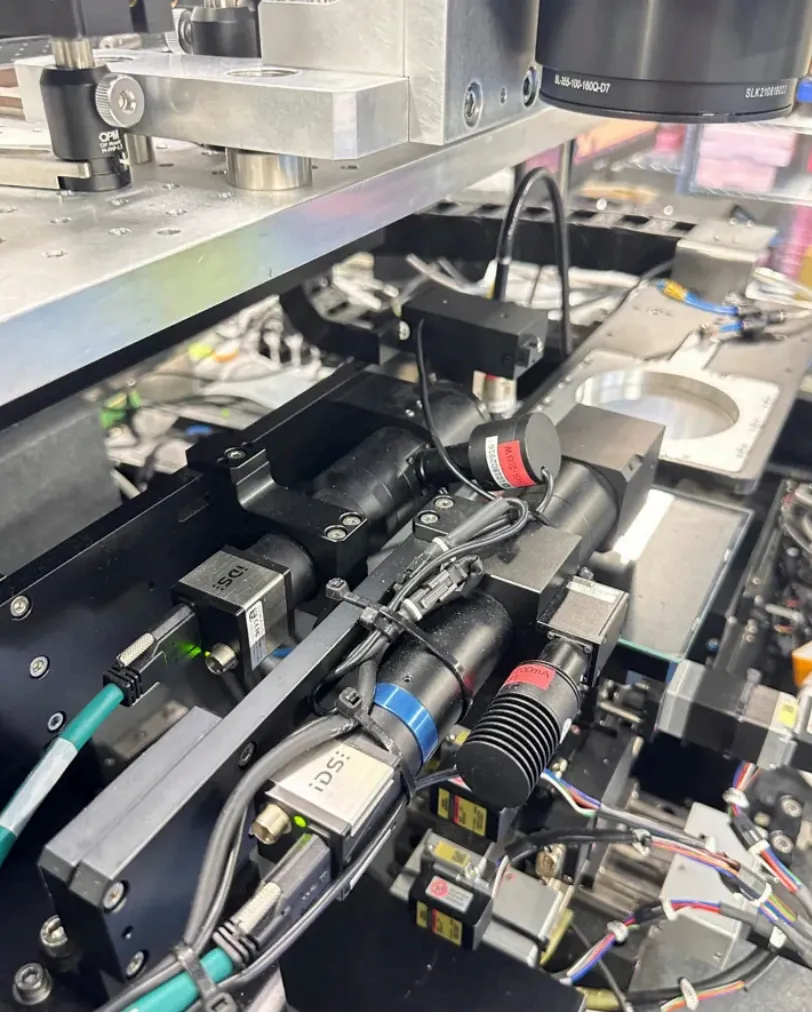

Both devices utilize the uEye CP series and features include:

By integrating IDS vision technology, manufacturers gained:

These two systems have been deployed in many top manufacturing enterprises in Taiwan and Asia, demonstrating the best combination of German high-end vision technology and advanced automation systems.

虹科 AR 遠程醫療解決方案整合醫療級 AR 智慧眼鏡、AI 即時翻譯與遠程會診技術,支援跨語言醫療溝通、臨床教學與國際醫療合作,推動智慧醫療流程數位化升級。

虹科 PCAN 卡應用於隧道挖掘設備電控系統,支援 CAN / CANopen / J1939 通訊,協助工程設備實現穩定資料傳輸、精準控制與高可靠性運作,適用於鑿岩台車與隧道施工設備。

KnowBe4 為企業應對香港《關鍵基礎設施保護條例》提供了化繁為簡的解決方案。面對第 24 條與第 25 條的嚴格挑戰,它將難以量化的「人為風險」轉變為可追蹤的實戰數據,不僅彌補了傳統評估的盲點,更為年度審核提供了證明控制措施「有效運作」的鐵證。透過自動化報告與持續演練,企業能在大幅降低安全風險的同時,輕鬆滿足監管要求,實現從「被動合規」到「主動防禦」的關鍵轉型。